Wadding machine and processing method for cotton slice

A cotton wadding and carding machine technology, which is applied to home appliances, bedspreads, loose filling materials, etc., can solve the problems of low production efficiency and complex structure of carding machine curtains, etc., and achieve high production efficiency and good connection performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

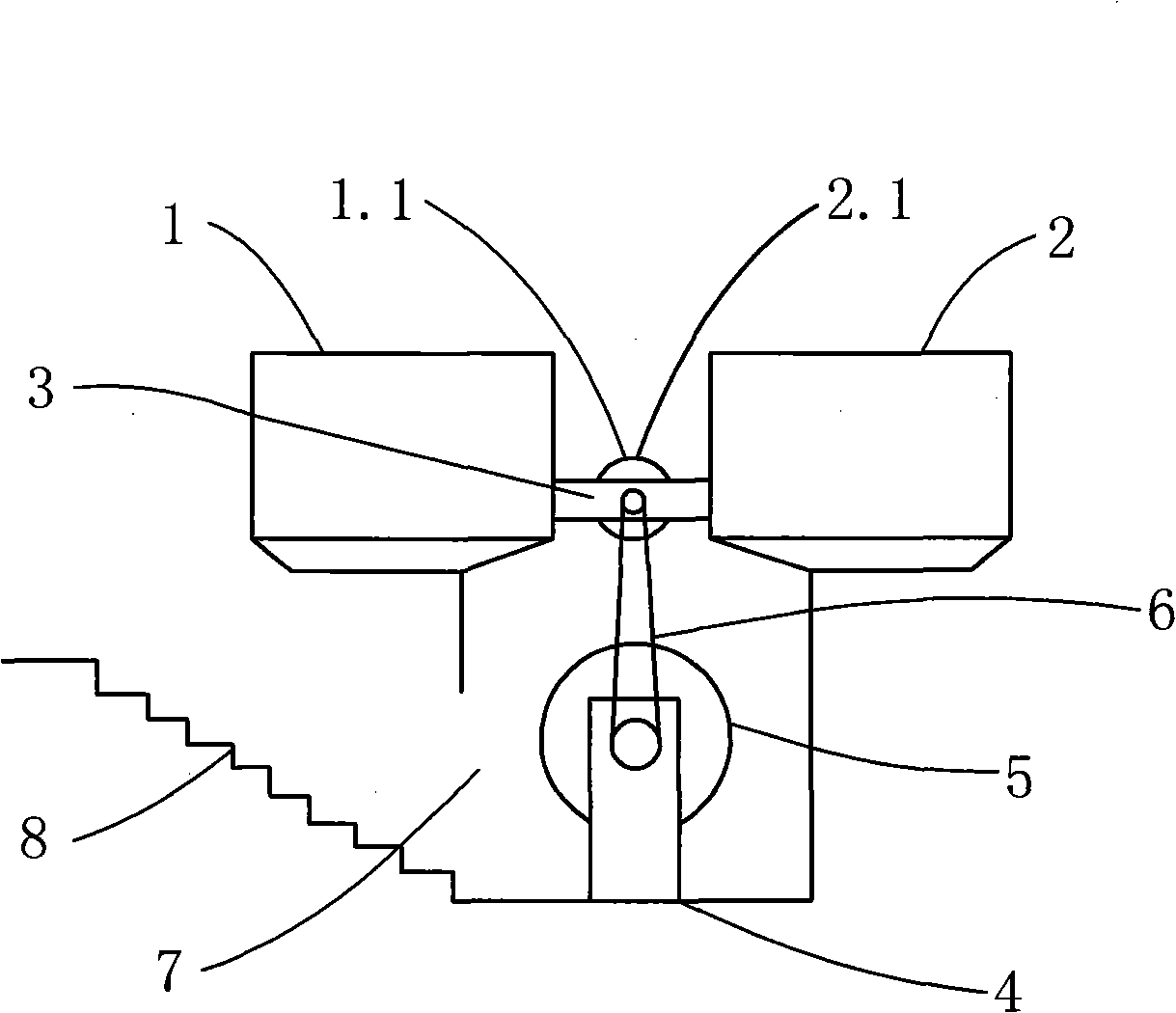

[0015] The main machine of the wadding machine adopts the existing carding machine and power device, and the two wadding machines are installed on the same plane at the top or at an oblique angle.

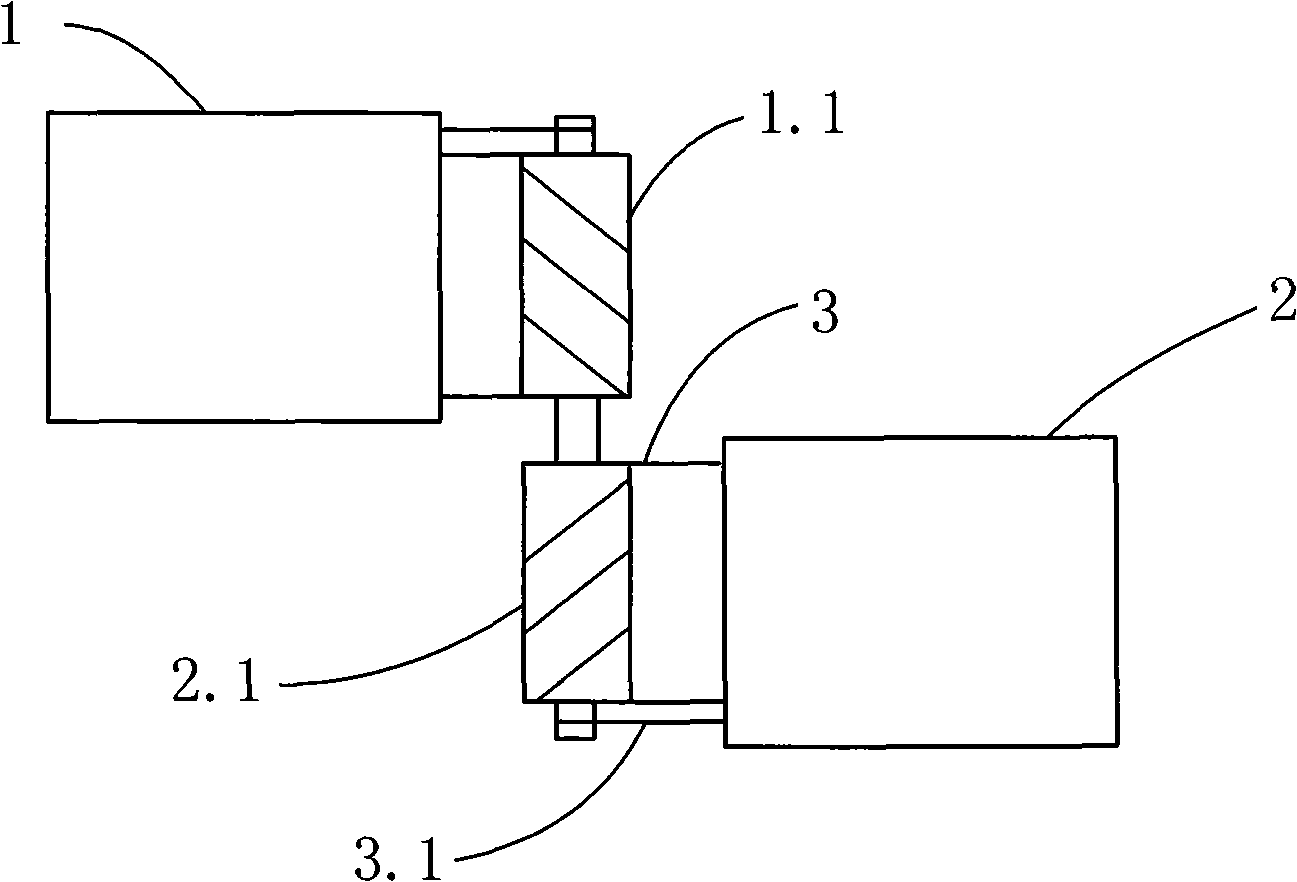

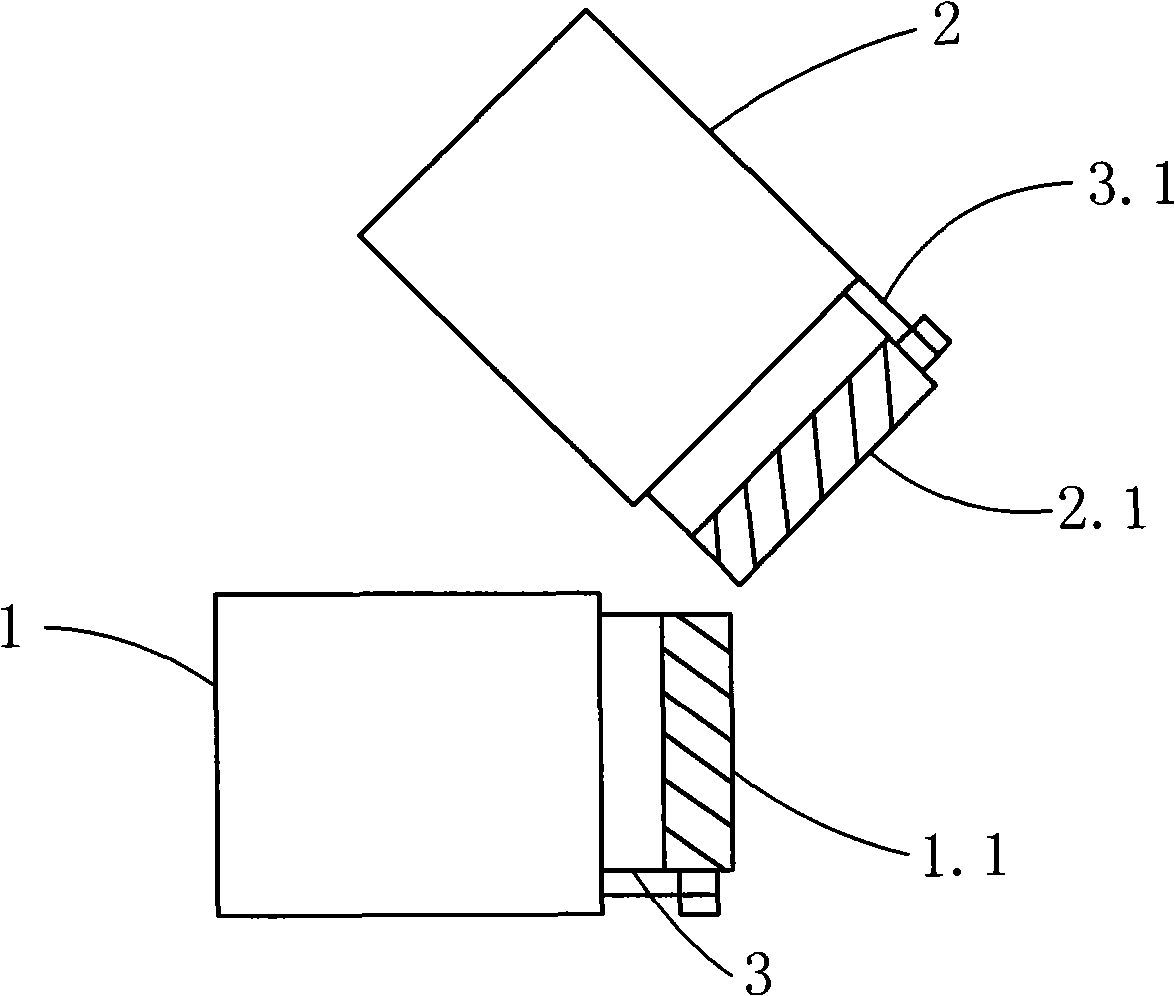

[0016] As shown in the figure,

[0017] Cotton wadding machine guide rollers 1.1 and 2.1 are respectively installed on cotton wadding machines 1 and 2 through guide roller brackets 3, and the power transmission belt 3.1 of the cotton wadding machine is installed on the power device of the cotton wadding machine host to connect with the power transmission of cotton wadding machine guide rollers 1.1 and 2.1 .

[0018] Below the ground plane of the lower part of the wadding machine, an underground room 7 is provided, and the underground room leads to above the ground by an ascending ladder 8. In the basement room, bedding cover cotton sheet rolling roller 5 is installed by quilt cover cotton sheet rolling roller support 4, and winding roller is dynamically connected with one end guiding

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap