Processing method before coating plastic parts

A processing method and technology for plastic parts, which can be applied to devices and coatings that apply liquid to the surface, which can solve the problems of plastic chips, high cost of manual grinding, pollution, etc., and achieve the effect of increasing adhesion and avoiding appearance differences.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

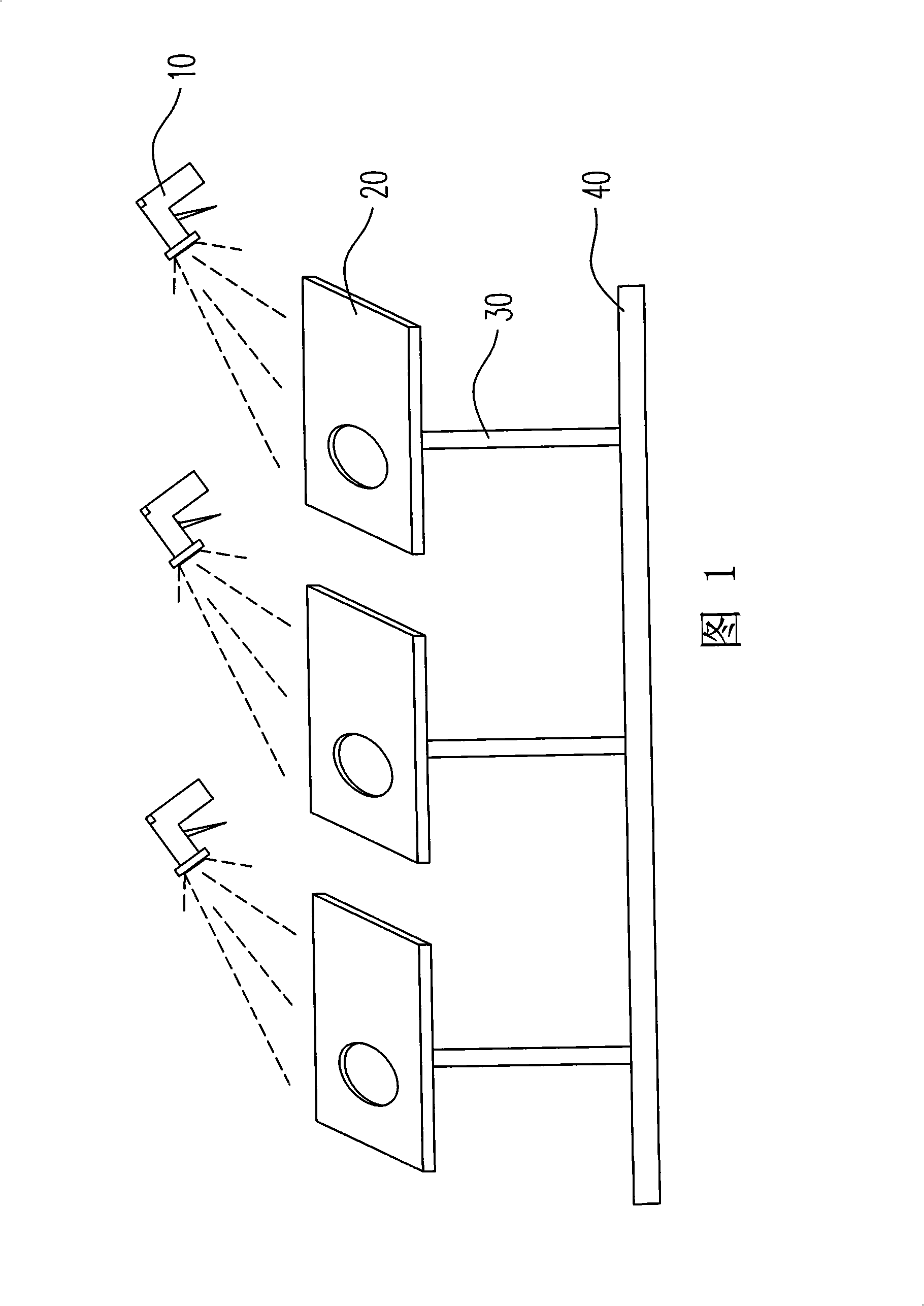

[0010] Please refer to Fig. 1, which is a schematic diagram of spraying of the present invention. The present invention mainly includes several spray guns 10 , several plastic parts 20 , several jig rods 30 and a ground rail cable 40 .

[0011] Wherein, the plastic parts 20 are plastic parts selected after injection molding, and the sprayed surface has obvious defects such as joint lines, air marks or mold marks, and each plastic part 20 is fixed on one end of each jig rod 30 , and the jig rod 30 can rotate around itself, and the other end of the jig rod 30 is fixed on the ground rail stay wire 40, and moves forward at a constant speed along the ground rail stay wire 40. In addition, the spray gun 10 is fixed and suspended above the plastic part 20.

[0012] The steps of the treatment method before the coating of the plastic part of the present invention are as follows: first, the anti-marking water is prepared, the main components of the anti-marking water are white oil and thi

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap