High energy-conserving and low energy consumption hydraulic pumping unit

A low energy consumption, hydraulic technology, applied in the direction of liquid displacement machinery, mining fluid, wellbore/well components, etc., can solve the problems of fragility and damage, complex transmission, high power consumption, etc., and achieve non-destructive and simple transmission , the effect of small power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

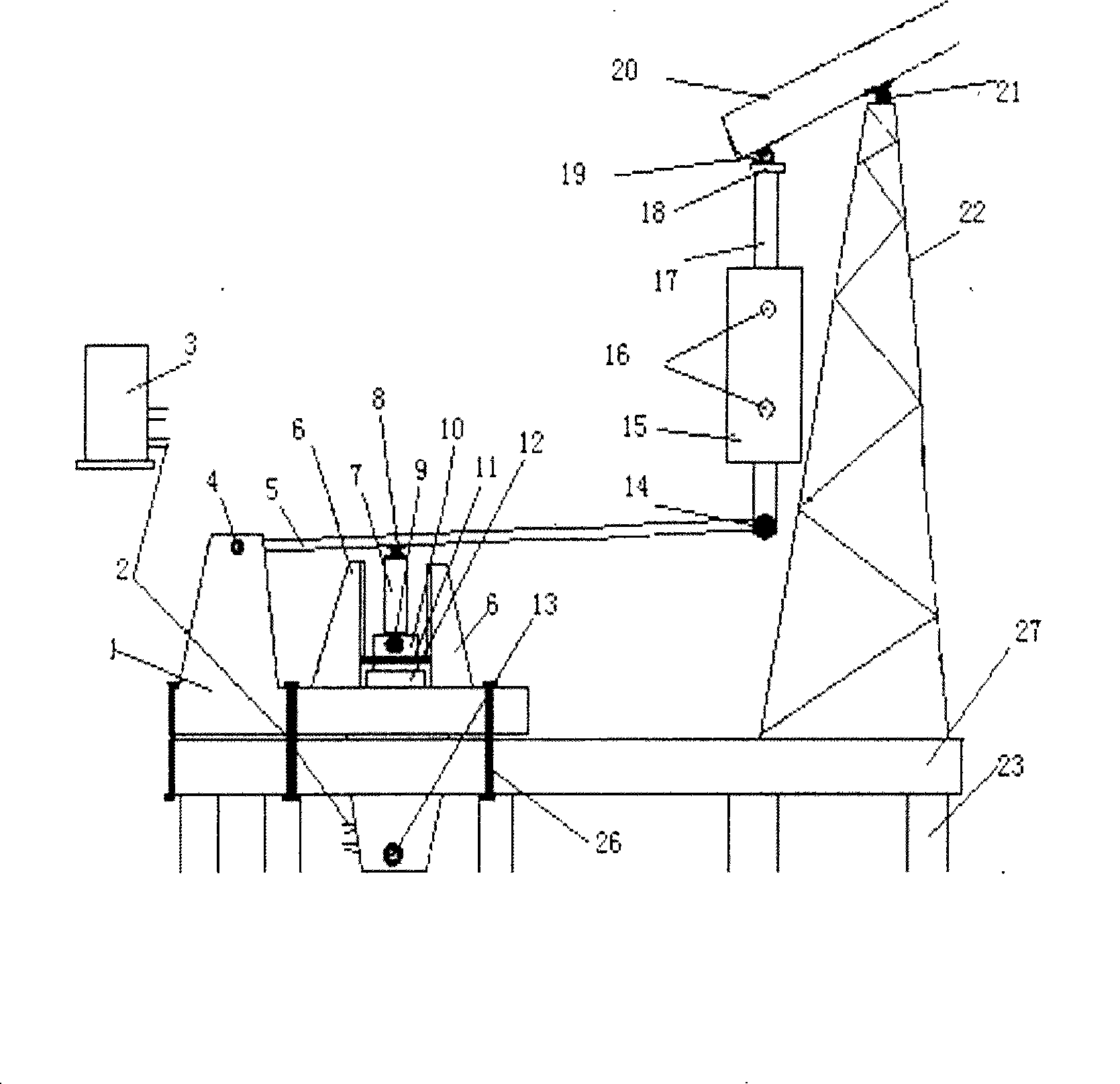

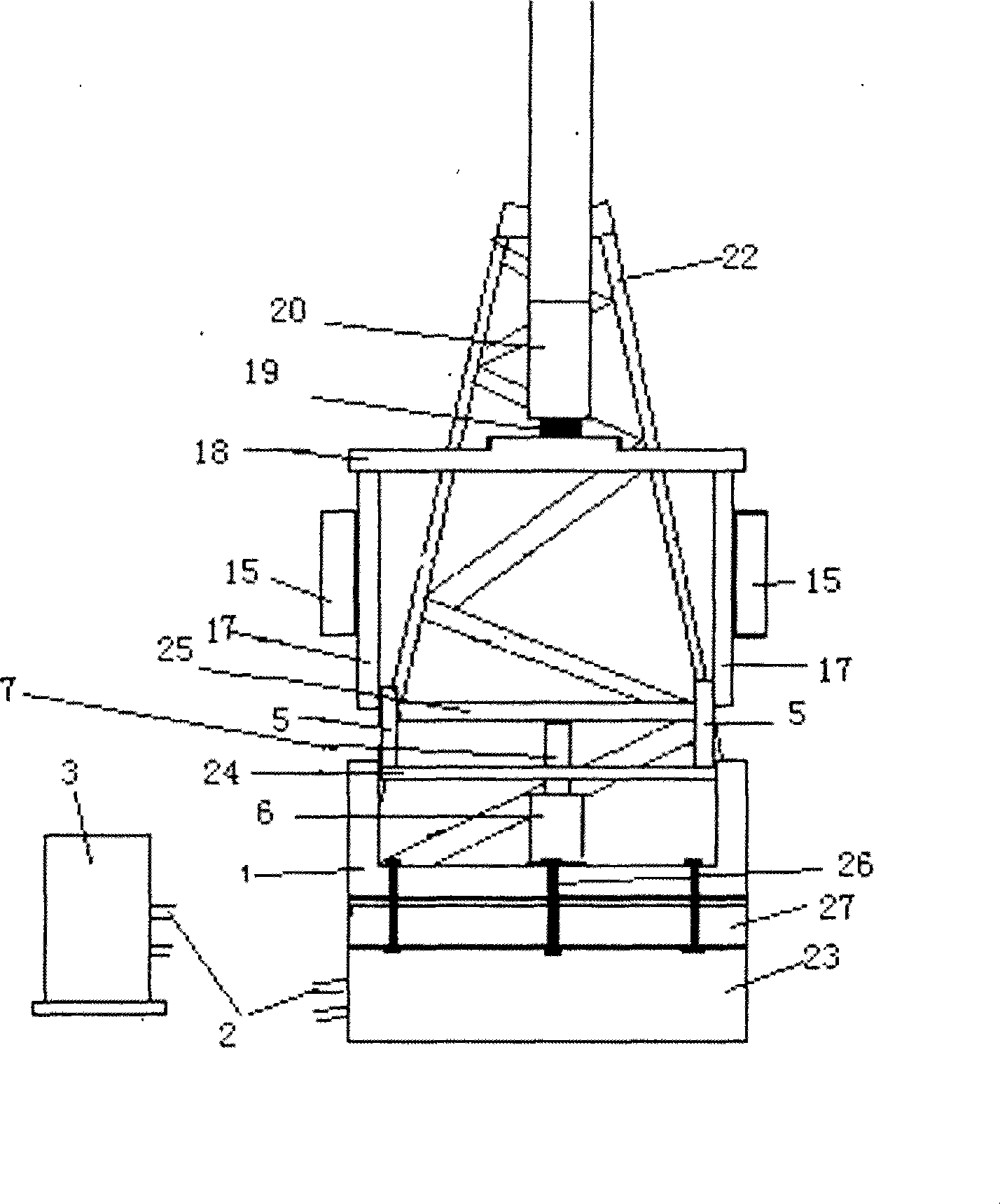

[0014] Referring to the accompanying drawings, a hydraulic pumping device with high energy saving and low energy consumption mainly includes a base 1, a beam 20 and its beam bearing 19, beam 18, connecting rod 17, counterweight 16 and connecting rod bearing 14. Connecting rod bearing 14 is connected with connecting rod 5, and the other end of this connecting rod 5 is connected with the connecting rod bearing 4 that is installed on the base 1 on the former base 27, and the middle part is equipped with top beam 25, and this top beam 25 lower end is connected with The hydraulic cylinder 12 and its hydraulic cylinder telescopic rod 10 installed on the base 1, the hydraulic telescopic rod 10 is connected with the hydraulic telescopic rod bearing 9 and the moving rod 7 are connected with the top cylinder bearing 8 and the top beam 25, the inlet and outlet of the hydraulic cylinder are connected with the hydraulic pressure The control station 3 is connected to the inlet and outlet 2 phas

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap