Triaxial synthesis oscillation/impact test device

A shock test and platform technology, which is applied in the field of oblique three-dimensional vibration/shock test equipment, can solve the problems of low work efficiency, many labors, and long time consumption, and achieve the effect of simple structure and high test operation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

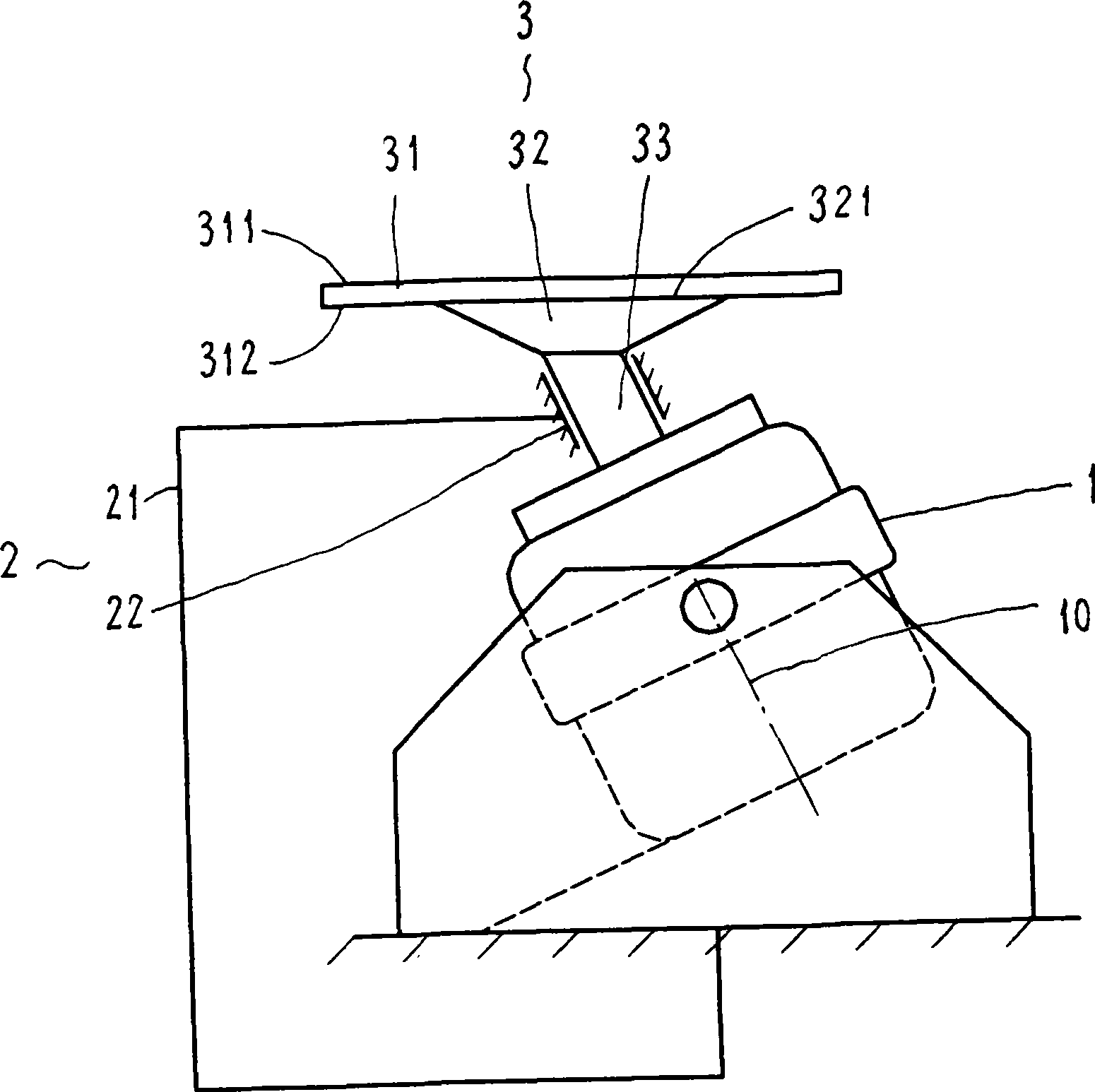

[0010] refer to figure 1 , The three-axis comprehensive vibration / shock test device includes a vibration table body 1, a base 2, and an extension table assembly 3.

[0011] The structure of the vibrating table body 1 is the same or similar to the existing hydraulic or electromagnetic vibrating table. The vibrating table body 1 is installed on the base 2 of the vibrating table surface through a fixing device, and the corresponding extended table surface is in an inclined state, that is, vibrating The axis 10 of the table body 1 (including the excitation source) and the vertical line form an inclination angle θ (such as figure 1 As shown), this structure can decompose the vibration in a single direction along the axis 10 of the shaking table body into the components of any axis on the three-dimensional coordinate axis, that is, one vibration test can meet the requirements of three-dimensional axial test. Compared with the traditional test The vibration excitation in one coordina

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap