Collating mechanism

A technology of collating and gripping pages, which is applied in the field of collating mechanisms, can solve problems such as inability to complete book block collating work and book block collating difficulties, and achieve the effects of reduced friction and reduced contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

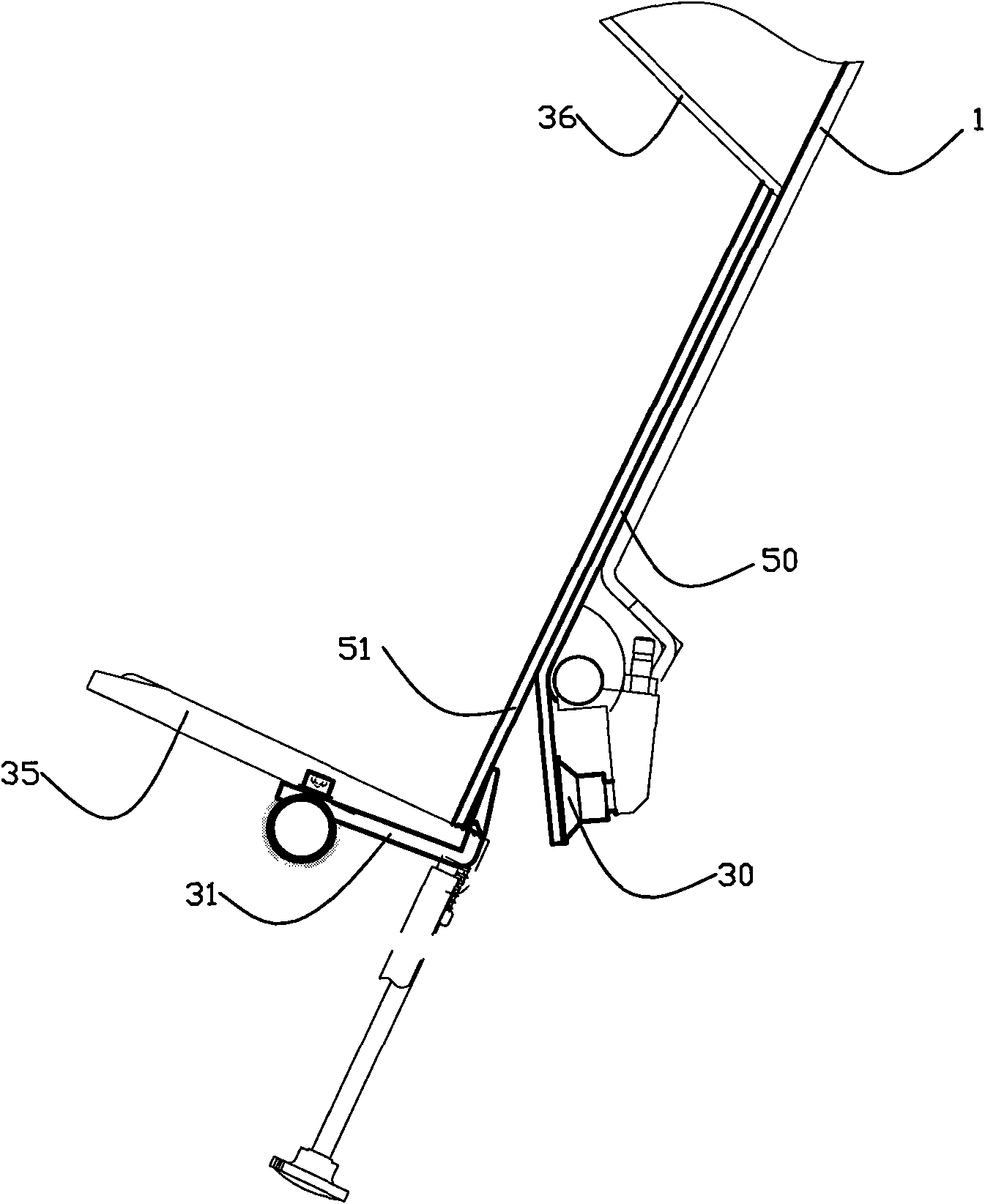

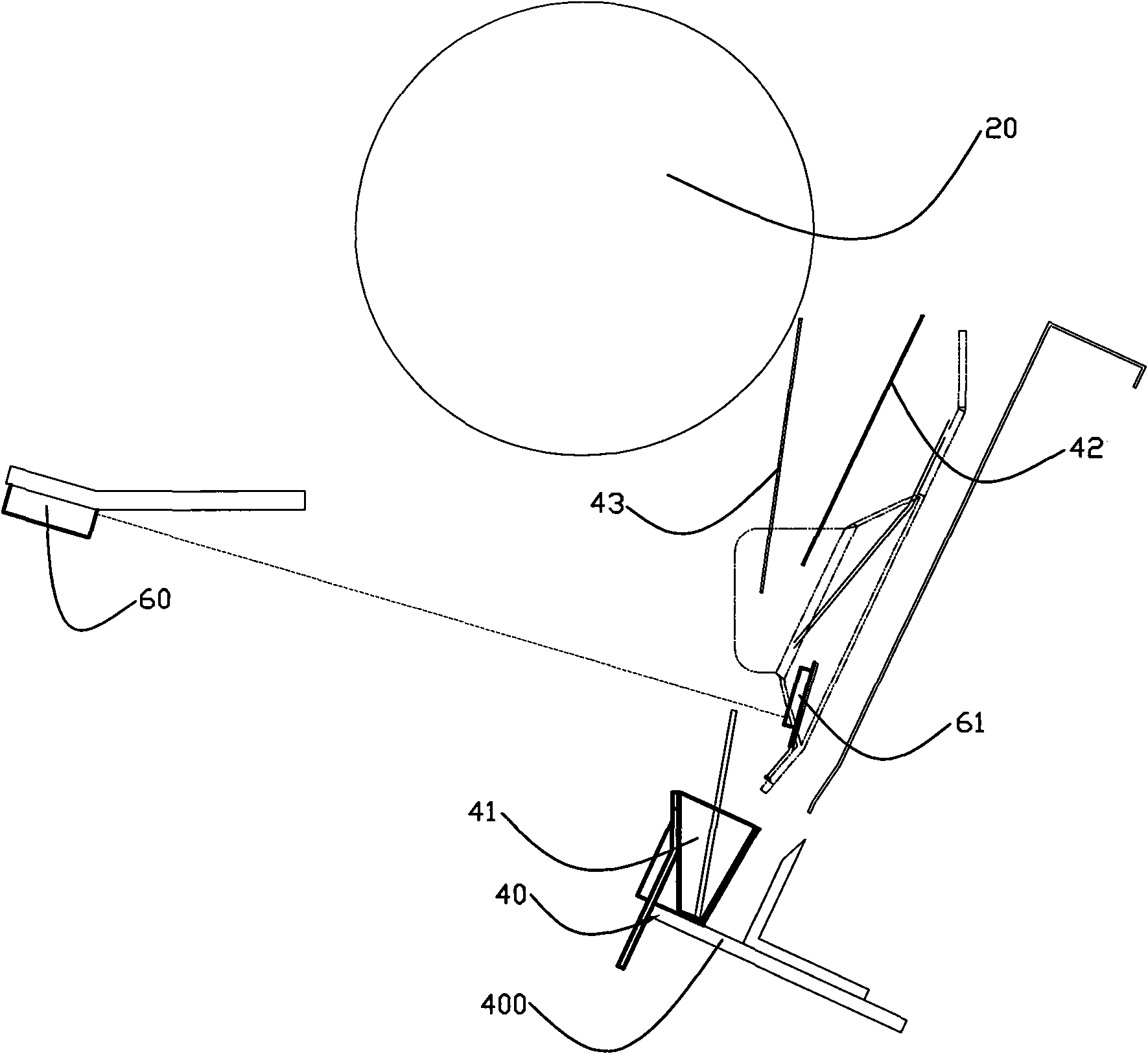

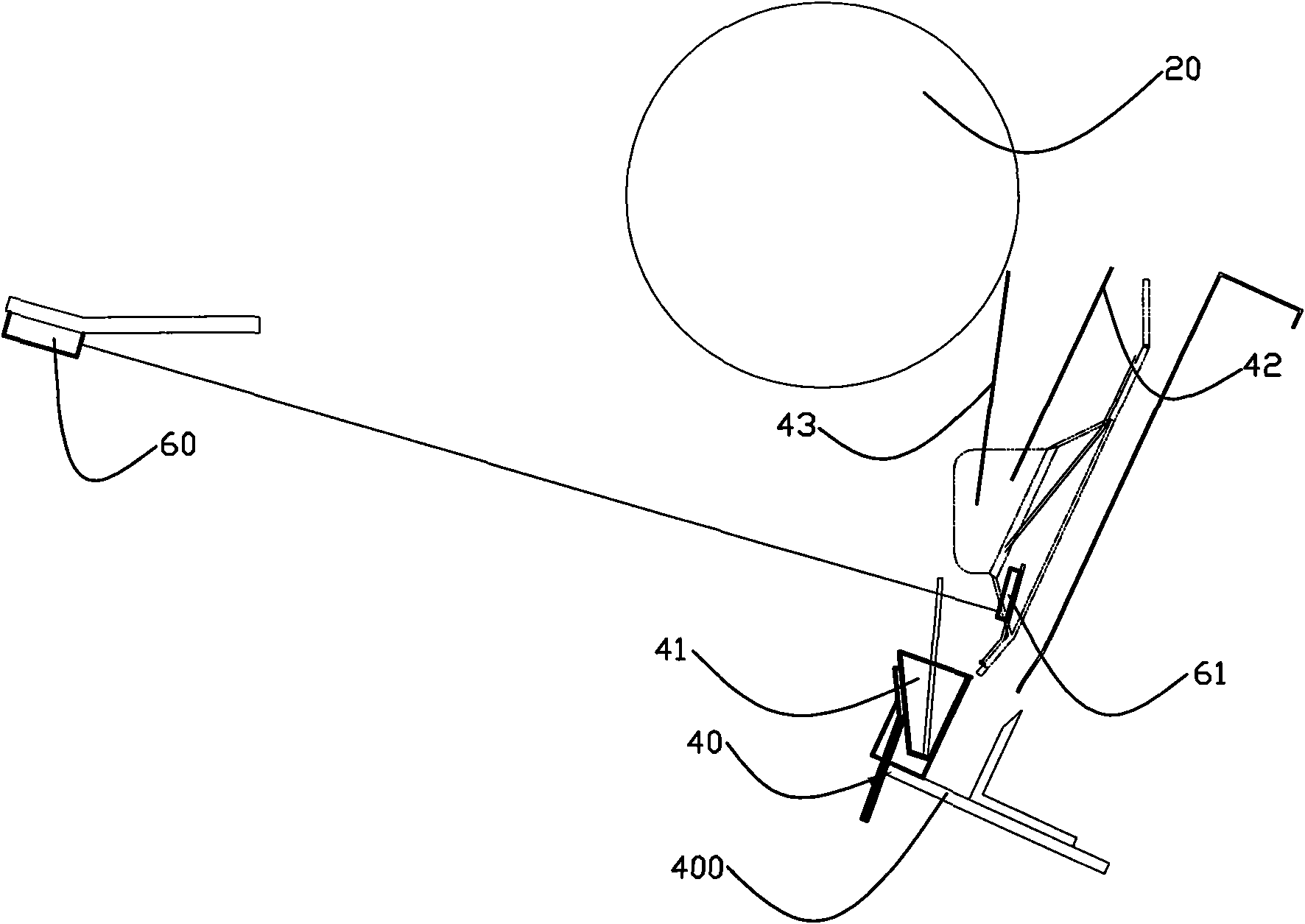

[0028] see Figure 3 to Figure 6 As shown, a collation mechanism of the present invention includes: a frame (not shown), a power element (not shown), a transmission device, a detection device, a control device (not shown), a post storage platform 1, Paging device, gripping page device, book receiving device (not shown). Post storage platform 1, paging device, gripping page device, and book receiving device (not shown) are successively arranged on the frame (not shown) according to the processing procedure. The power element (not shown) is connected with the transmission device, the paging device, the gripper device, and the book collection device and drives the transmission device to drive the paging device, the gripper device, and the book collection device (not shown). The transmission device includes a main shaft (not shown), a transmission unit, and a drive unit (not shown). The main shaft (not shown) is connected with the sorting device and the gripping device. The transp

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap