Method for manufacturing solar battery

A technology of solar cells and manufacturing methods, applied in the direction of final product manufacturing, sustainable manufacturing/processing, circuits, etc., can solve problems affecting the quality of silicon wafers, high cost of photomask manufacturing process, and complicated steps, etc., to improve photoelectric conversion efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

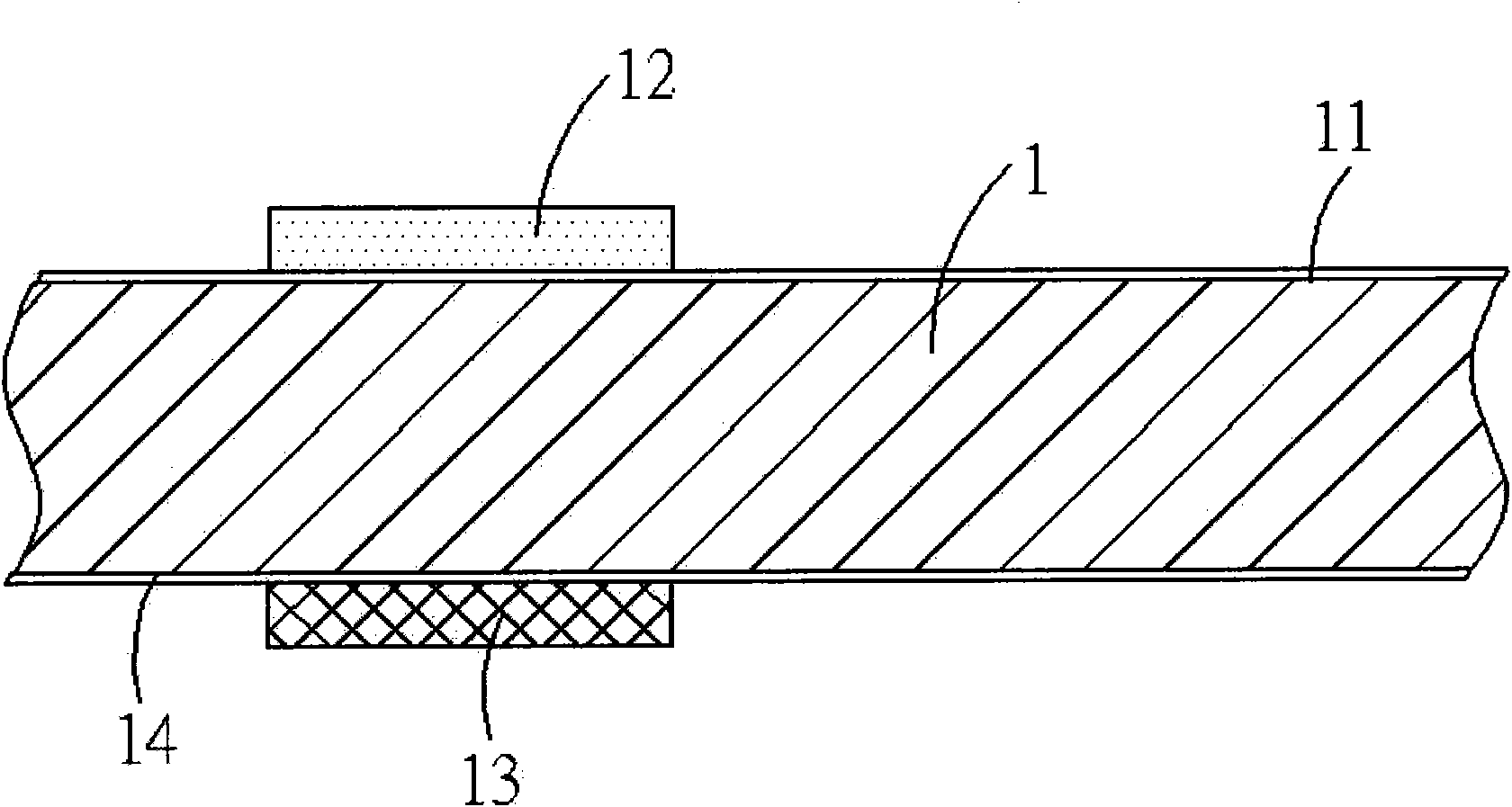

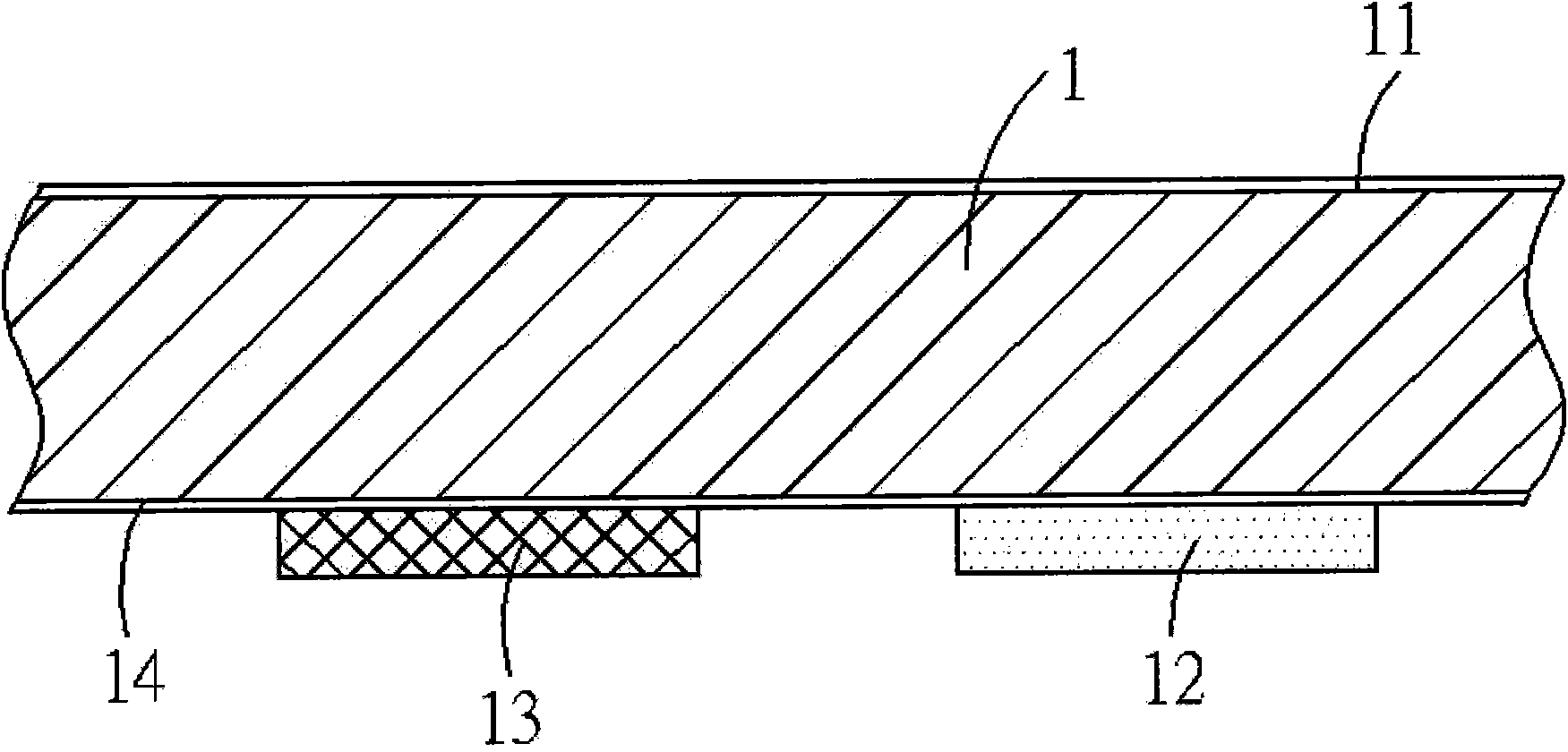

[0023] The characteristics of the present invention can be clearly understood by referring to the detailed description of the drawings and embodiments of the present case.

[0024] The manufacturing method of the solar cell of the present invention includes at least the following steps:

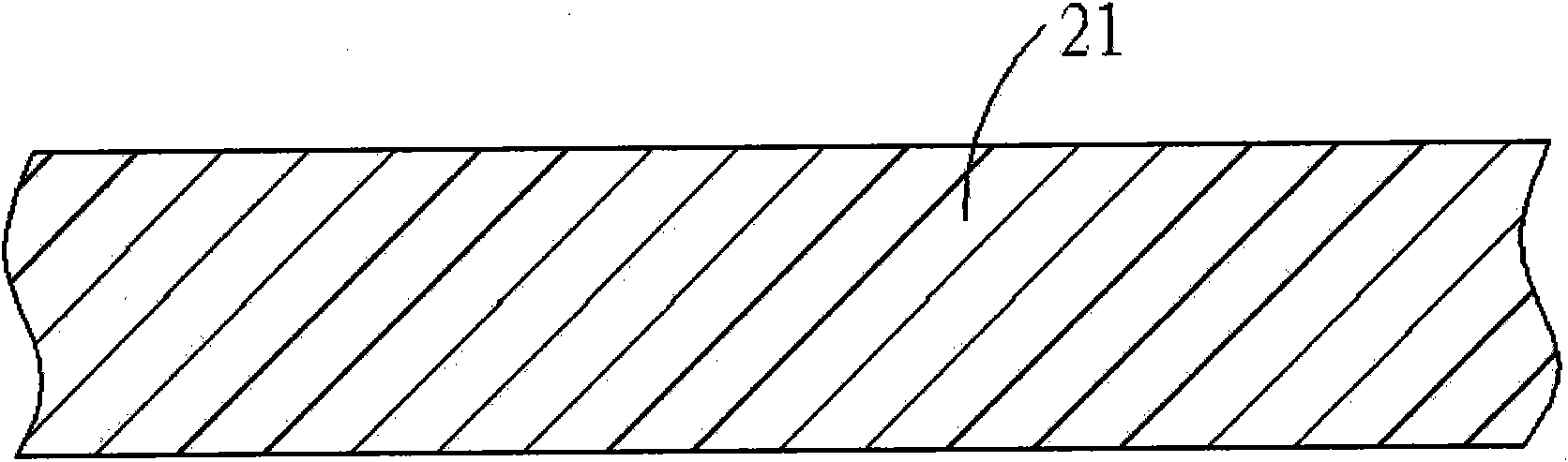

[0025] Step A, provide a wafer 21, such as image 3 As shown, the wafer 21 may be an n-type monocrystalline silicon wafer;

[0026] Step C1: First and second passivation layers 22 and 23 are provided, and first and second passivation layers 22 and 23 are respectively provided on the bottom and top surfaces of wafer 21, such as Figure 4A As shown, the first and second passivation layers 22, 23 can be ultra-thin, with a thickness of about 20-50 The first passivation layer 22 can be made of amorphous silicon or silicon with dopants such as carbon, nitrogen and oxygen deposited on the bottom surface of the wafer 21, and the second passivation layer 23 can be made of silicon oxide or doped non-crystalline

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap