Straight barrel type concrete mixing transportation truck

A technology for mixing trucks and concrete, which is applied to cement mixing devices, clay preparation devices, chemical instruments and methods, etc., can solve the problem of not overcoming energy consumption area and other problems, and achieve the effects of simple structure, reduced energy consumption, and reduced area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

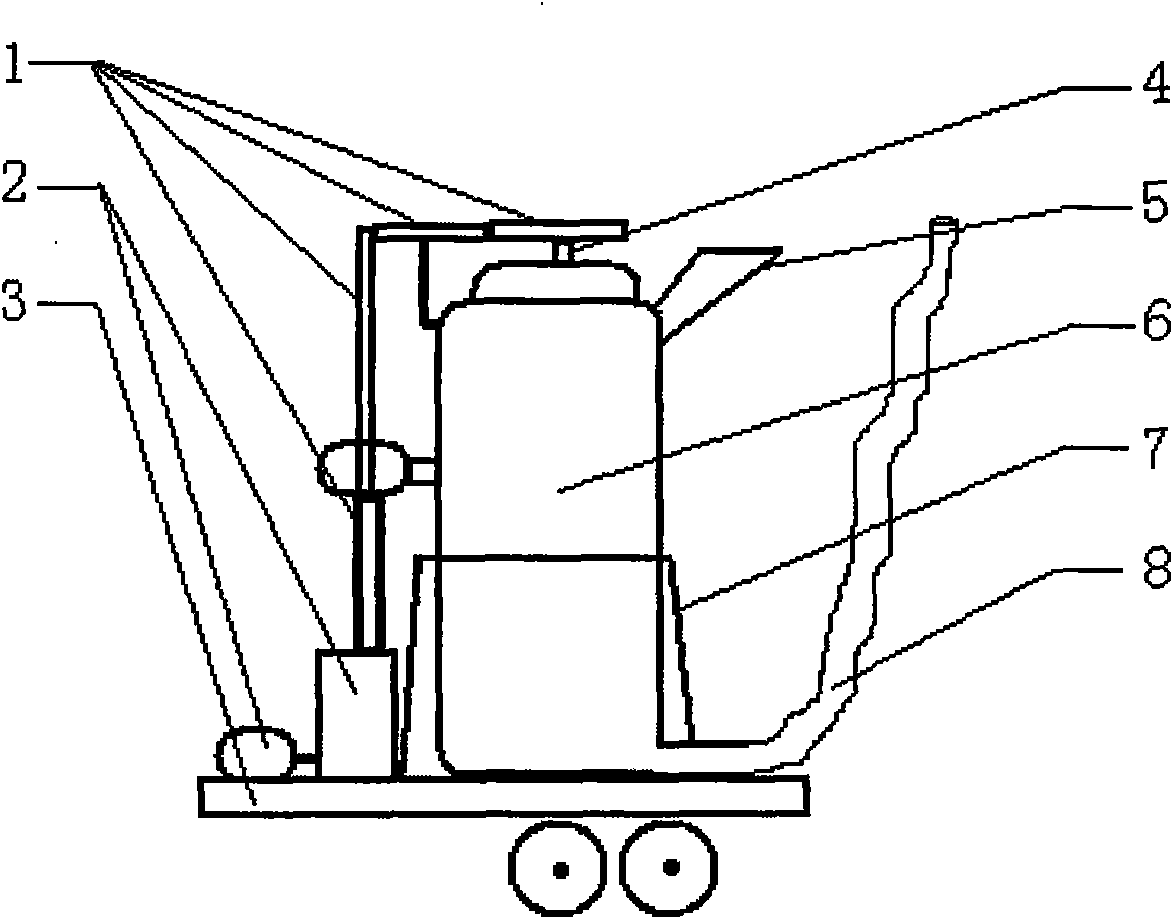

[0010] The straight bucket type concrete mixer truck provided by the present invention is composed of a straight bucket 6, a fixed frame 7, agitating blades, a transmission mechanism 1, a power mechanism 2, a material inlet 5 and a discharge pipe 8, wherein the power mechanism 2 is fixed on the vehicle On the chassis 3, there are power take-offs, reducers, hydraulic motors, hydraulic pumps, and electronic control units to provide power, which is the prior art; the straight barrel 6 is cylindrical, and the straight barrel 6 is erected and fixed on the automobile chassis 3 through the fixing frame 7 On; the stirring blade has a rotating shaft 4, and the stirring blade is inserted into the straight barrel 6 from the upper end of the straight barrel 6; the transmission mechanism 1 is fixed on the automobile chassis 3 or the wall of the straight barrel 6, connects the power mechanism 2 and the rotating shaft 4, and transmits power to Agitating blades; the feed inlet 5 is located on the

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap