Phosphor doping type nano titanium dioxide having efficient sunlight catalytic capability and preparation method thereof

A nano-titanium dioxide, catalytic performance technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of poor photocatalytic activity of nitrogen-doped titanium dioxide, and achieve the effect of increasing the phase transition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

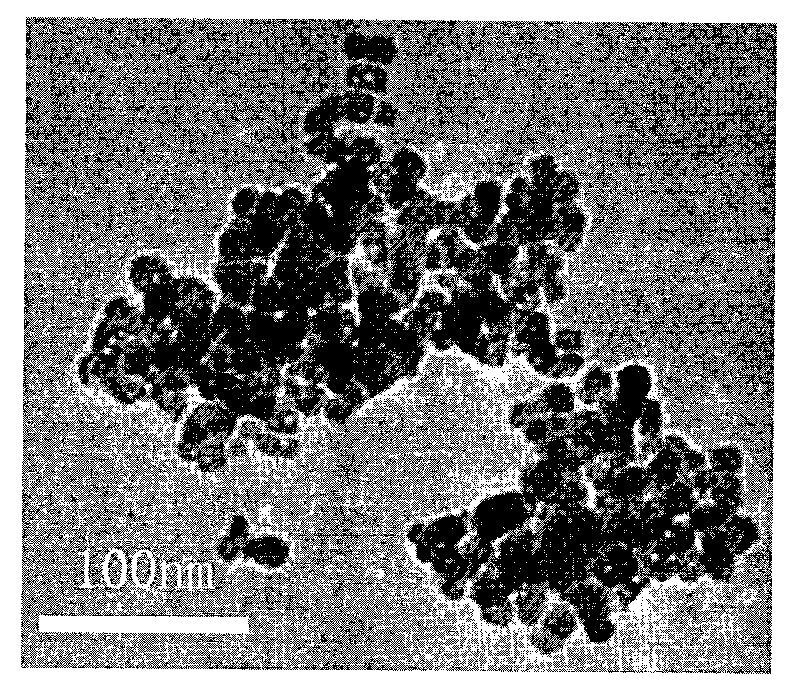

[0032] Example 1 Using tetrabutyl titanate as the titanium source and phosphoric acid as the phosphorus source, P-doped titanium dioxide nanoparticles were prepared at room temperature.

[0033] In molar ratio [H 3 PO 4 ] / [Ti(OC 4 h 9 ) 4 ]=0.044 / 1 sampling, a typical preparation method is to take 20mL of anhydrous C 2 h 5 OH in a 50mL Erlenmeyer flask, add 4mL Ti(OC 4 h 9 ) 4 , then add 4 mL ice CH 3 COOH, stir and mix with a magnetic stirrer, the obtained solution is A solution; take another 20mL Erlenmeyer flask, measure 20mL of anhydrous C 2 h 5 OH in the conical flask, then measure 5mL of HCl aqueous solution with a pH value of 2 in the conical flask, then add 30μL of analytically pure H 3 PO 4 , the solution obtained by oscillating and mixing is B solution; transfer B solution into the dropping funnel and slowly drop it into A solution, keep magnetic stirring, and drop it for about 2 hours to obtain a stable transparent sol, and then rotate the sol to obtain

Embodiment 2

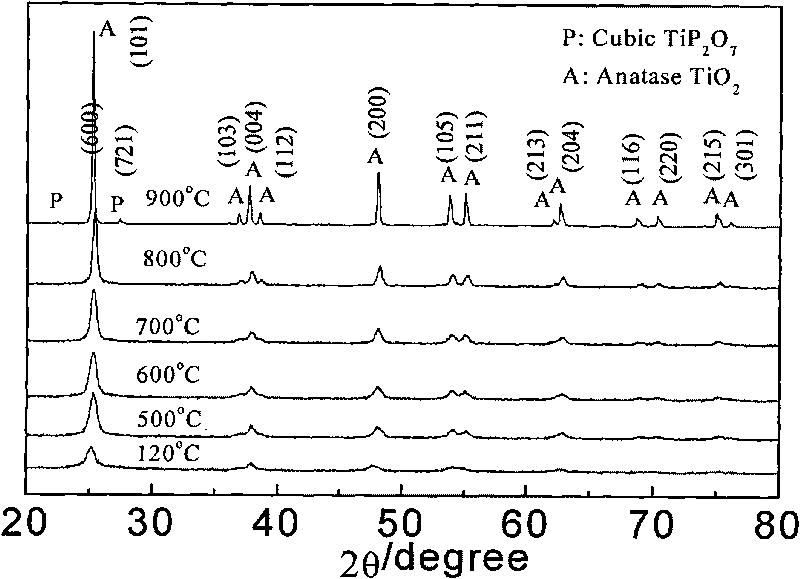

[0034] Example 2 Catalytic Degradation of Rhodamine B in P-doped Samples Calcined at Different Temperatures under Sunlight

[0035] Weigh 5 mg of P-doped samples calcined at different temperatures (400 °C, 500 °C, 600 °C, 700 °C, 800 °C) into 5 quartz cups, and then add 25 mL of 0.01 g / L rhodamine B solution to avoid After 15 minutes of photo-ultrasound, 5 quartz cups were irradiated under outdoor sunlight for 30 minutes at the same time, and 3 mL of degraded turbid liquid was taken out from the 5 quartz cups, centrifuged, and the supernatant was taken to measure the absorbance A value at the peak position of 553 nm. According to the formula D%=(1-A t / A 0 )×100 to calculate the decolorization rate.

Embodiment 3

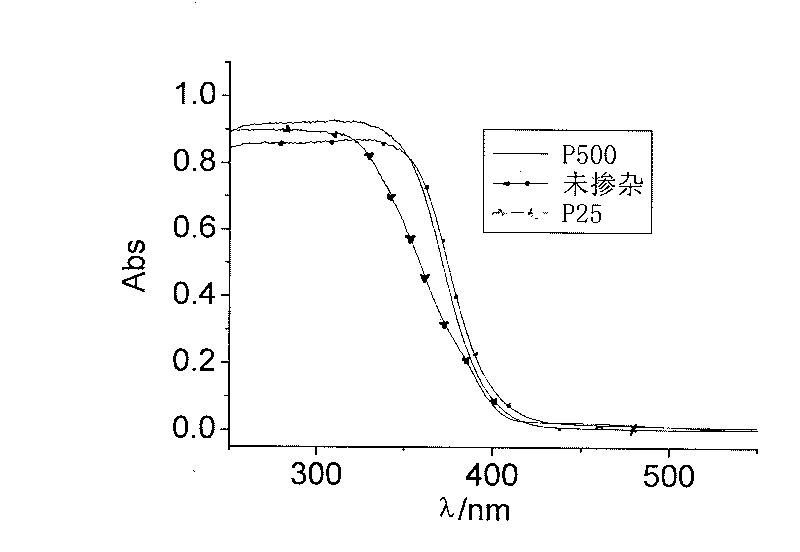

[0036] Example 3 Different types of titanium dioxide degrade rhodamine B under sunlight

[0037] Weigh 5 mg of undoped titanium dioxide, P-doped titanium dioxide, and P25 into the same quartz cups, and then add 25mL 0.01g / L Rhodamine B solution to the three quartz cups, avoid light and ultrasonically for 15 minutes, and then take another The same concentration of rhodamine B solution was also added to the same quartz cup, and the four quartz cups were placed in the outdoor sunlight for 40 minutes, and samples were taken every 10 minutes, centrifuged, and the supernatant was taken to test the absorption spectrum, and the light was taken after four samples. , read the absorption A value at the 553nm peak position, according to the formula D%=(1-A t / A 0 )×100 to calculate the decolorization rate, get Figure 5 .

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap