Separate type filling method of goaf

A goaf and barrier technology, which is applied in the fields of backfill, mining equipment, earthwork drilling, etc., can solve the problems of limited control of surface subsidence, limited application and promotion, complicated filling process, etc., and achieve subsidence control. Remarkable, high filling efficiency and filling density, and simple filling method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

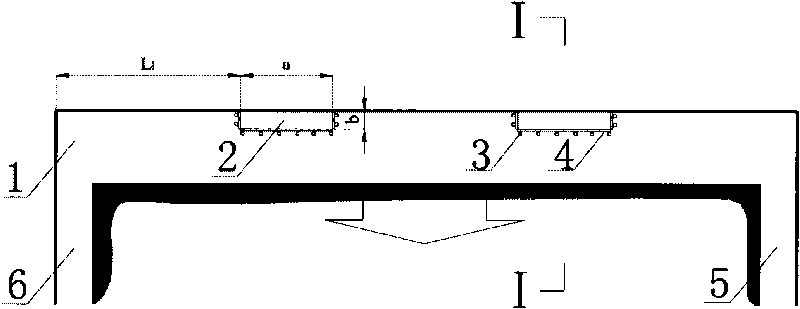

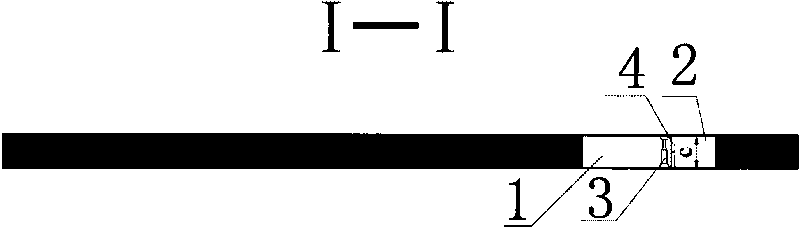

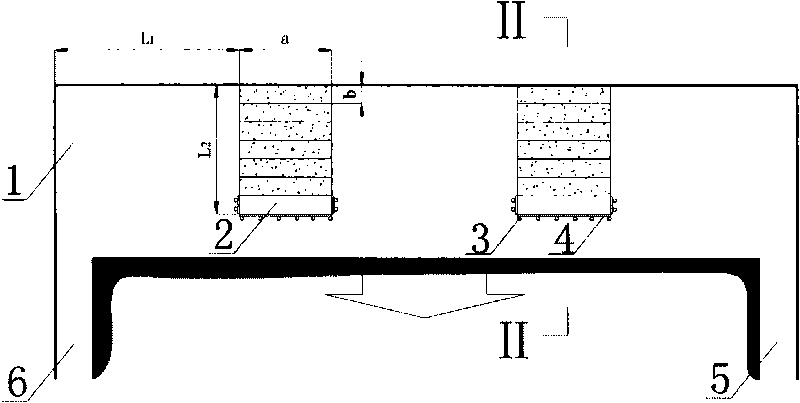

[0033] Embodiment one, Figure 1 to Figure 8 as shown,

[0034] a. In the mined-out area 1 to be filled, along the advancing direction of the coal mining face, the interval distance L is arranged longitudinally 1 Hang multiple flexible filling bags 2; the length a of the flexible filling bag 2 is about 10m to 20m, the width b is about 2m to 3m, and the height c is the same as the mining height of the working face;

[0035] b. A plurality of individual pillars 3 are arranged at intervals on the exposed side of the hanging flexible filling bag 2;

[0036] c. Erecting a template 4 on the outside of the flexible filling bag 1 and relying on the single pillar 3;

[0037] d. Fill the flexible filling bag 2 with high-water material through the filling pipe until it is full;

[0038] e. After the high-water material is solidified, the template 4 and the single pillar 3 are removed to complete a row of filling barriers;

[0039] f. With the advancement of the coal mining face, the ver

Embodiment 2

[0043] Embodiment two, Figure 9 ~ Figure 14 as shown,

[0044] a. In the mined-out area 1 to be filled, along the advancing direction of the coal mining face, the span L of the cut-off area is arranged horizontally 3 Hang multiple flexible filling bags 2; the length a of the flexible filling bag 2 is 10m-20m, the width b is 2m-3m, and the height c is the same as the mining height of the working face;

[0045] b. A plurality of individual pillars 3 are arranged at intervals on the exposed side of the hanging flexible filling bag 2;

[0046] c. Erection of the template 4 on the outside of the flexible filling bag 2 and relying on the single pillar 3;

[0047] d. Fill the flexible filling bag 2 with high-water material through the filling pipe until it is full;

[0048] e. After the high-water material is solidified, the template 4 and the single pillar 3 are removed to complete a row of filling barriers;

[0049] f. With the advancement of the coal mining face, when the advanc

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Separation distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap