Method for producing large-power LED lamp without halo

A LED light, high-power technology, applied to optical elements, light sources, point light sources, etc. used to change the spectral characteristics of emitted light, can solve the problem of multiple light colors, difficult control of light shapes, and derivatives to application directions, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

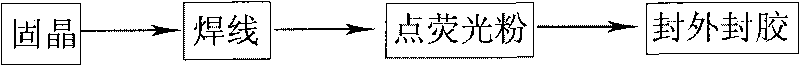

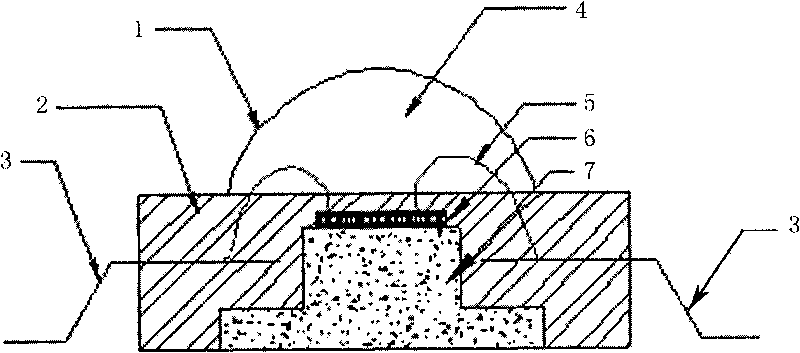

[0019] The following will combine Figure 1 to Figure 6 The present invention is further described: a method for manufacturing a halo-free high-power LED lamp, which is mainly realized by the following methods:

[0020] The first step: solid crystal.

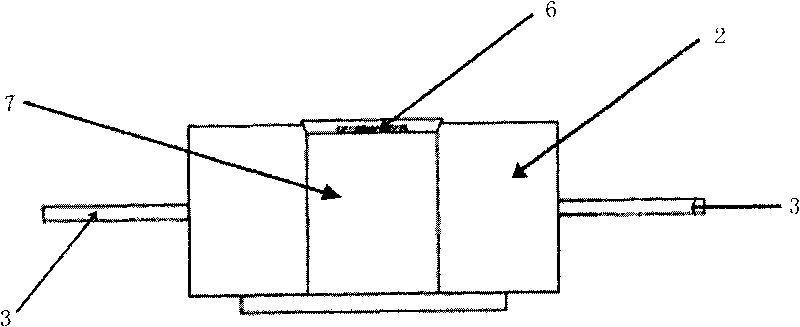

[0021] In this step see image 3 The chip 6 is bonded and fixed on the copper column 7 installed on the support 2 by silver glue, and the support 2 is formed by PPA plastic material, and the copper column 7 can help the chip 6 to dissipate heat.

[0022] Step Two: Soldering the Wires.

[0023] In this step see Figure 4 That is, the four electrodes on the chip 6 are connected to the two positive and negative electrodes provided on the positive and negative pins 3, so that the LED lamp forms an electrical circuit.

[0024] The third step: point fluorescent powder.

[0025] In this step see Figure 5 , that is, smear the fluorescent glue 8 composed of phosphor powder and colloidal silicon on the wafer 6, so that the fluorescent

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap