Convex double-layer pressure sensitive film based on MEMS process and FP cavity optical fiber acoustic sensor

A sensitive film and sensor technology, which is applied in the field of acoustic sensors, can solve the problems of large deformation of the sensitive film, flat spectral curve, and small hard deformation of the material, and achieve the effects of high reflectivity, reduced round-trip loss, and good deformation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the purpose, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

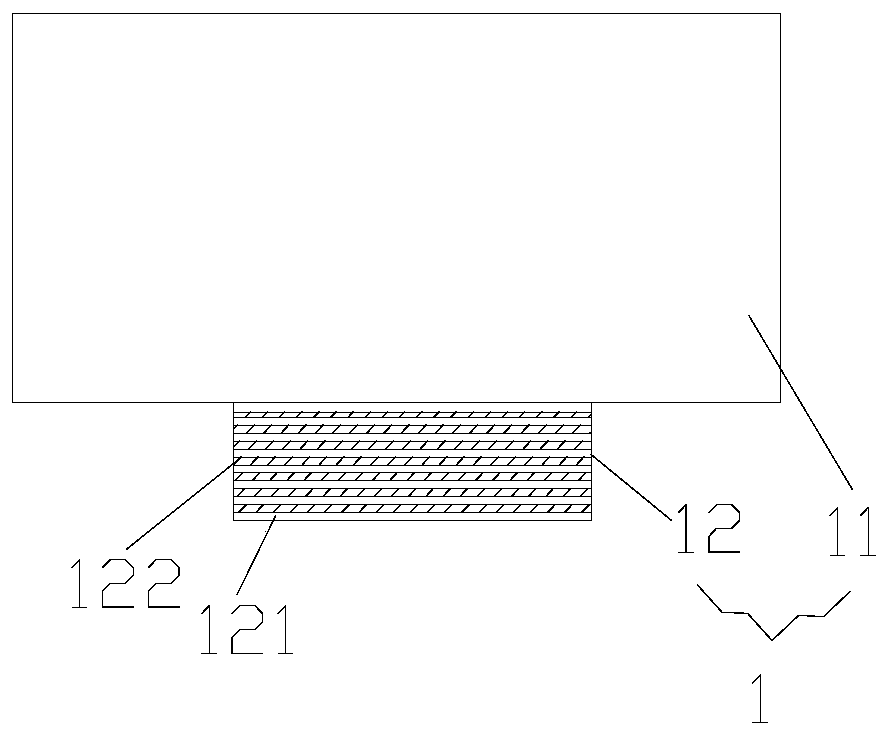

[0031] Please refer to figure 1 , the embodiment of the present invention provides a kind of outward convex double-layer pressure-sensitive film 1 based on MEMS technology, comprises soft film 11 and the medium hard film 12 that is plated under soft film 11, and the diameter of soft film 11 is larger than medium hard film The diameter of 12 makes the soft film 11 and the medium hard film 12 form a convex structure. The soft film 11 is a rubber film or silicone film made of PDMS, and its surface is smooth and clean. The thickness of the soft film 11 is 0.5-10 μm.

[0032] The thickness of dielectric hard film 12 is 500-2000nm, and it comprises several first dielectric layers 121 and several second dielectric layers 122, and the refractive index of first diel

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap