On-line monitoring device for roll gap of plate blank continuous casting machine

A slab continuous casting machine and monitoring device technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of inability to continuously monitor the roll gap on-line, affect the operation rate of the continuous casting machine, and unfavorable roll gap abnormalities, etc., and achieve fast measurement speed, The effect of improving maintenance efficiency and reducing quality loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0031] Example one

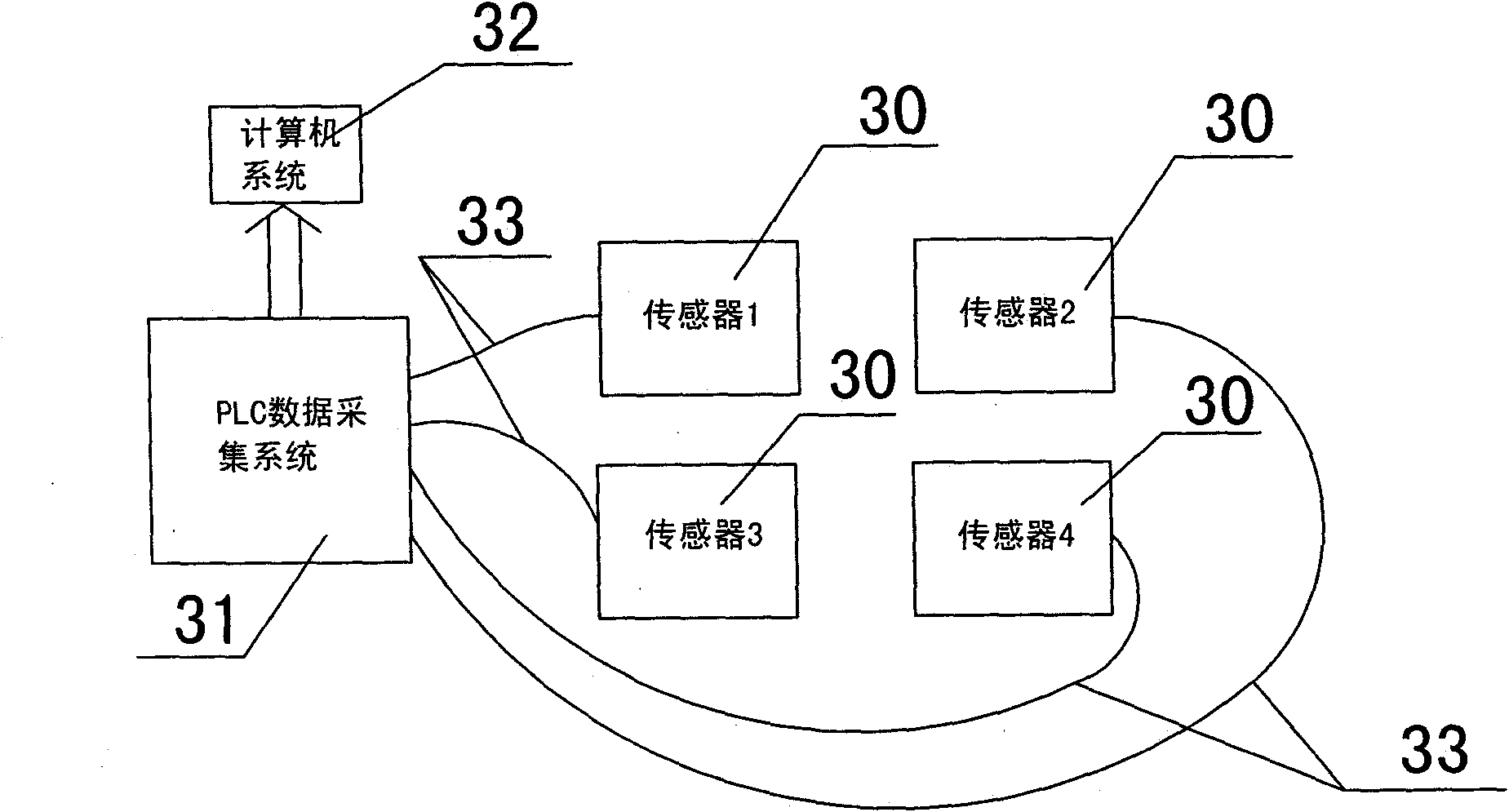

[0032] The basic composition of the on-line monitoring device for the roll gap of the slab continuous casting machine in this embodiment is as follows figure 1 As shown, there are two pairs respectively arranged near the two ends of the continuous casting roll (see figure 1 The sensor terminals 30 of the displacement sensors 1, 2, 3, 4 of ), and their signal output terminals are respectively connected to the PLC data acquisition system 31 of the monitoring circuit through the signal cable 33, and then transmitted to the computer information processing system 32.

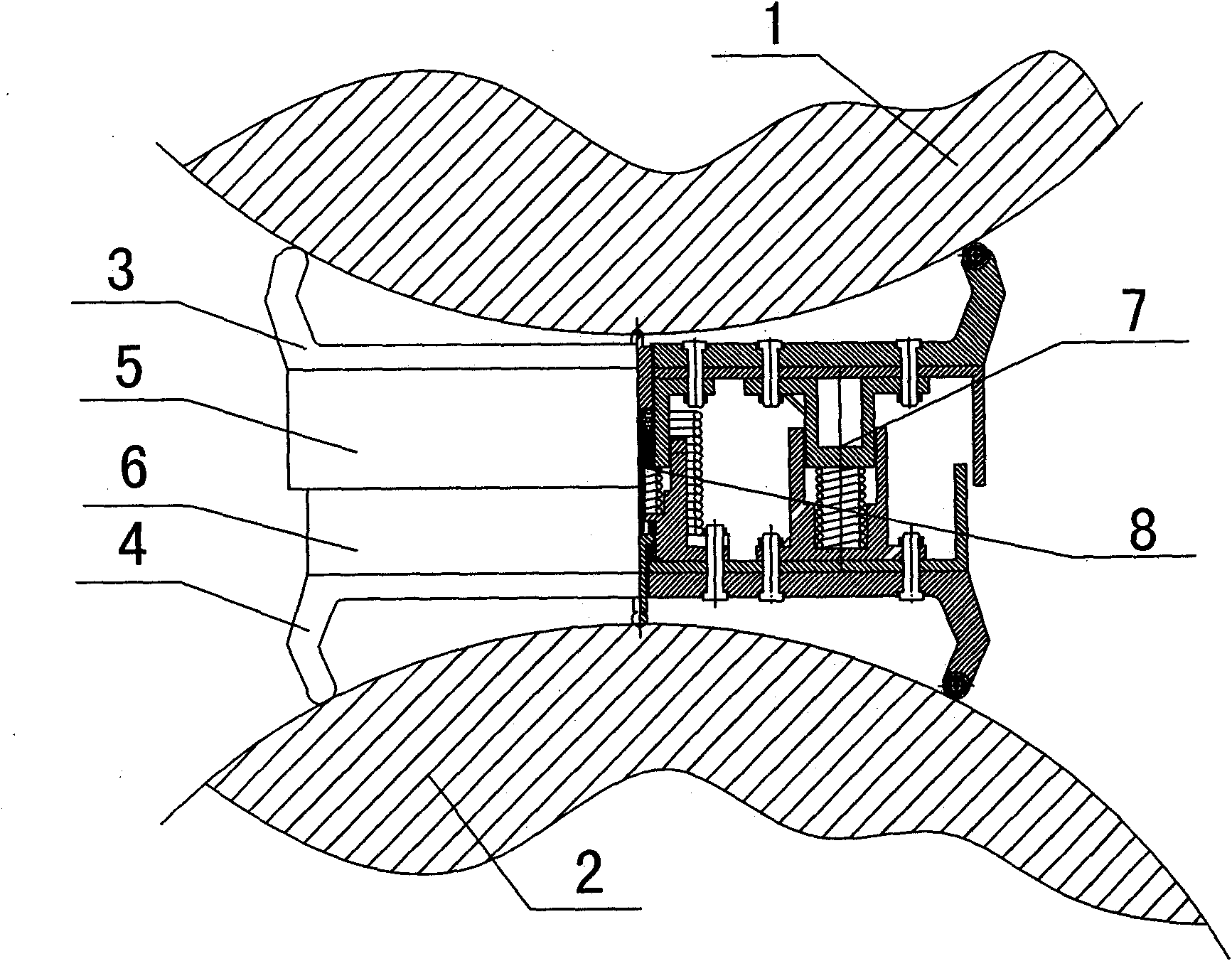

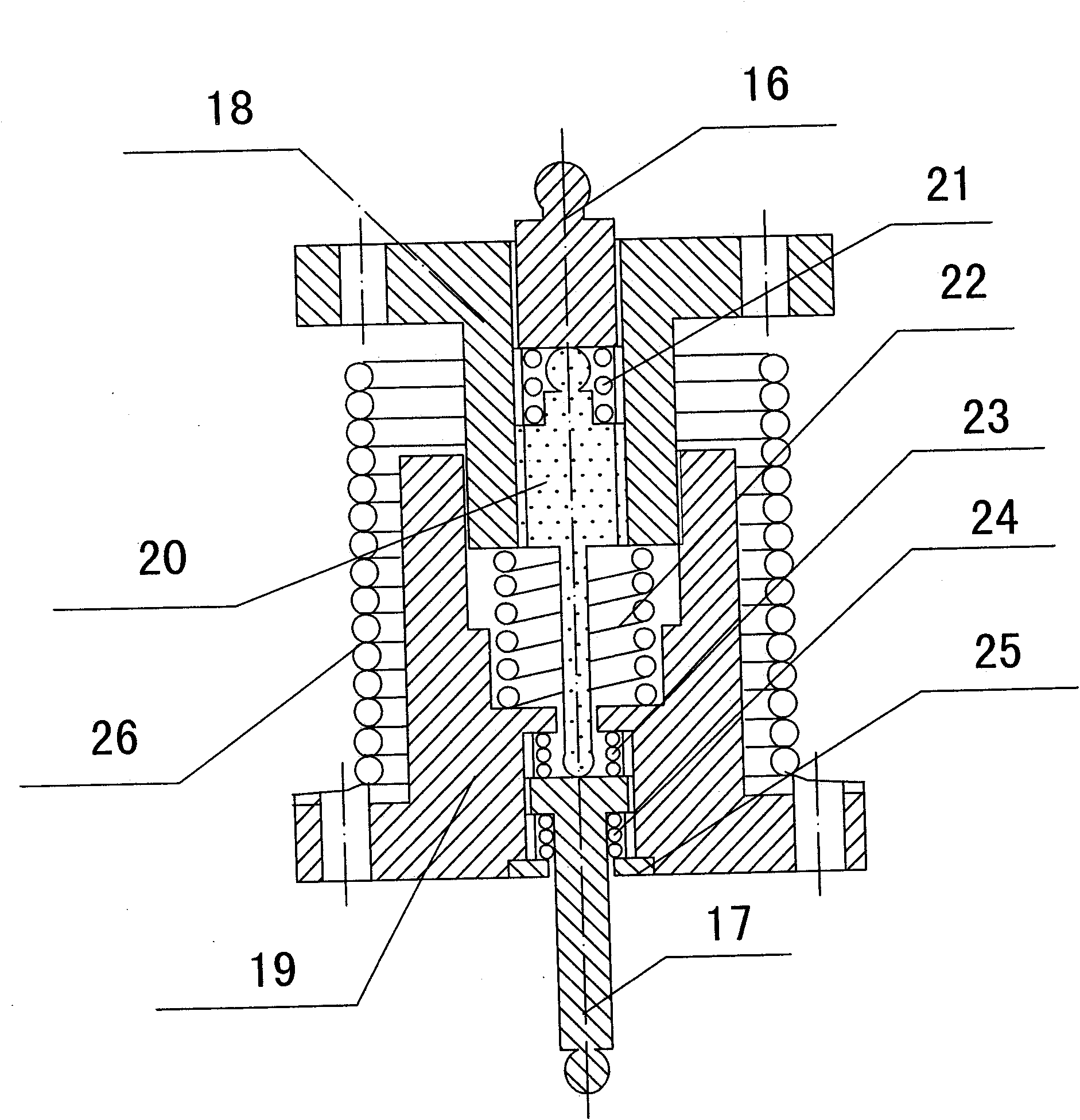

[0033] Such as figure 2 with image 3 As shown, the middle of each displacement sensor 20 is fixed to the middle of the inner surface of the upper measuring positioning plate 3 through the upper positioning seat 18 of the measuring rod, and the upper and lower telescopic sensing ends of the displacement sensor 20 are respectively inserted into the upper and lower positions of the measuring rod. In the ce

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap