Contact dynamic sealing method and disc sealing ring dynamic sealing device

A sealing ring and dynamic sealing technology, applied in the direction of engine sealing, transmission box, engine components, etc., can solve the problems of sealing ring leakage, bearing and shaft wear, etc., and achieve the effects of long service life, convenient installation and disassembly, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

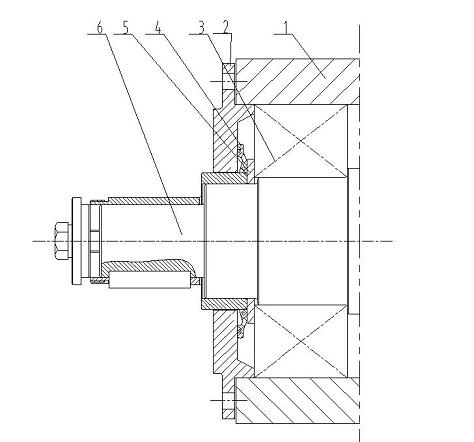

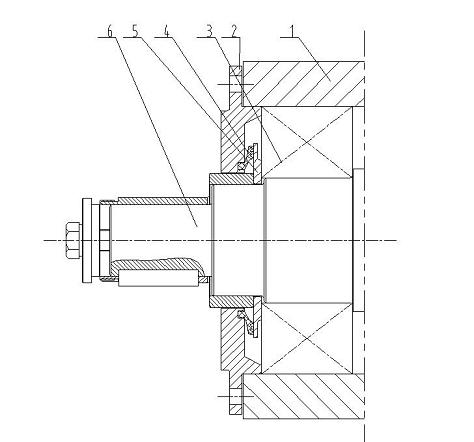

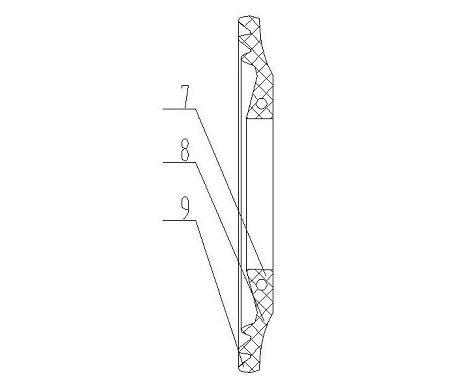

[0013] The contact dynamic sealing method is: near the leakage gap of the transmission device, there is a dish-shaped sealing ring composed of a positioning ring, an elastomer and a sealing ring, and the positioning ring of the sealing ring is installed on the journal of the transmission shaft or box. The inner side of the body bearing sealing gland, so that the sealing ring of the sealing ring is in close contact with the inner surface of the bearing sealing gland or the side of the bearing retaining ring, blocking the leakage gap between the transmission shaft and the box bearing sealing gland, realizing the Transmission seals.

[0014] The embodiment of the present invention will be described below in conjunction with the accompanying drawings, which mainly consists of a transmission case 1, a bearing sealing gland 2, a bearing 3 and a drive shaft 6. A bearing retaining ring 5 is installed on the journal of the transmission shaft 6, and a disc sealing ring 4 is installed betwe

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap