Cutting machine for cutting silicon chips

A technology of cutting machine and silicon wafer, applied in the field of cutting machine and silicon wafer cutting machine, can solve the problems such as the weak connection between the silicon wafer and the pallet, affecting the yield of the silicon wafer, and the falling damage of the silicon wafer, so as to achieve a simple structure, Improve yield and avoid drop damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with accompanying drawing.

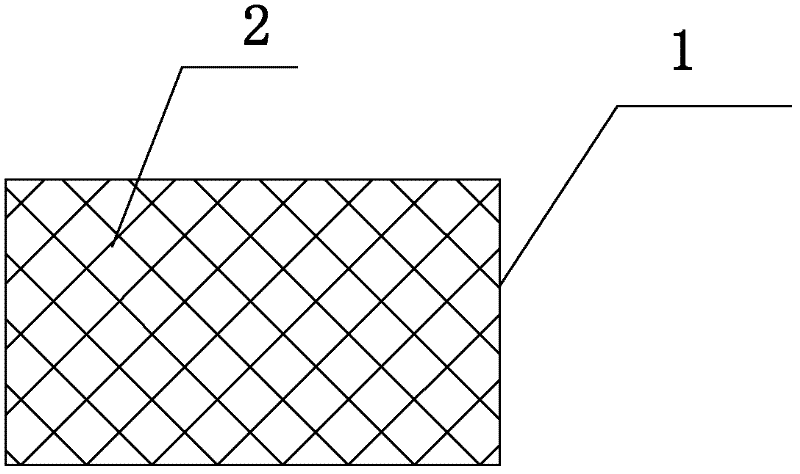

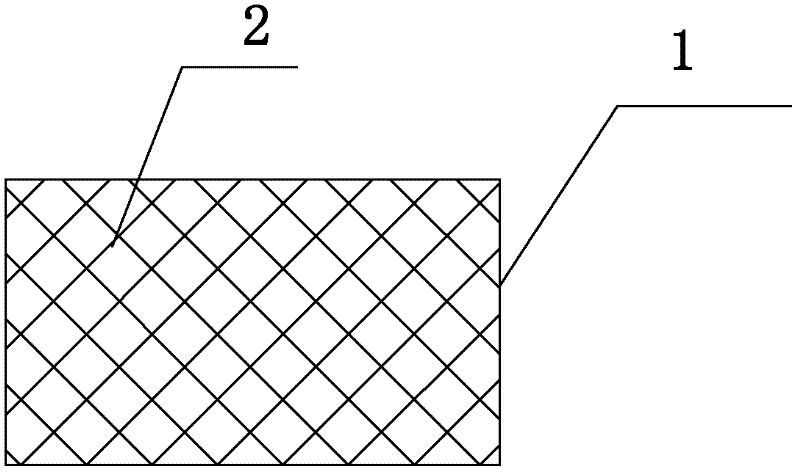

[0009] As shown in the figure, in order to solve the above technical problems, a cutting machine for cutting silicon wafers according to the present invention includes a supporting plate 1, a glass plate 2, the supporting plate 1 and the glass plate 2 are connected into one body, and the supporting plate 1 is used to To connect the silicon chip, the surface of the supporting plate 1 in contact with the silicon chip is provided with a knurling pattern 2. Since the surface of the supporting plate in contact with the silicon chip is provided with a knurling pattern, the friction between the supporting plate and the silicon chip is improved. force, so that the connection between the silicon wafer and the supporting plate is more firm, and the silicon wafer is prevented from falling and damaged, thereby improving the yield of the silicon wafer; in addition, the present invention has

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap