Device for recovering fine-particle coal

A recovery device and fine particle technology, which is applied in the field of fine particle coal recovery device, can solve the problems that the efficiency of coal recovery affects the operation efficiency of the coal humidity control system, affects the production quality and cost of the coking process, and the viscosity of fine coal powder is large. Achieve the effect of preventing further deterioration of the situation, eliminating potential safety hazards, and reducing concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

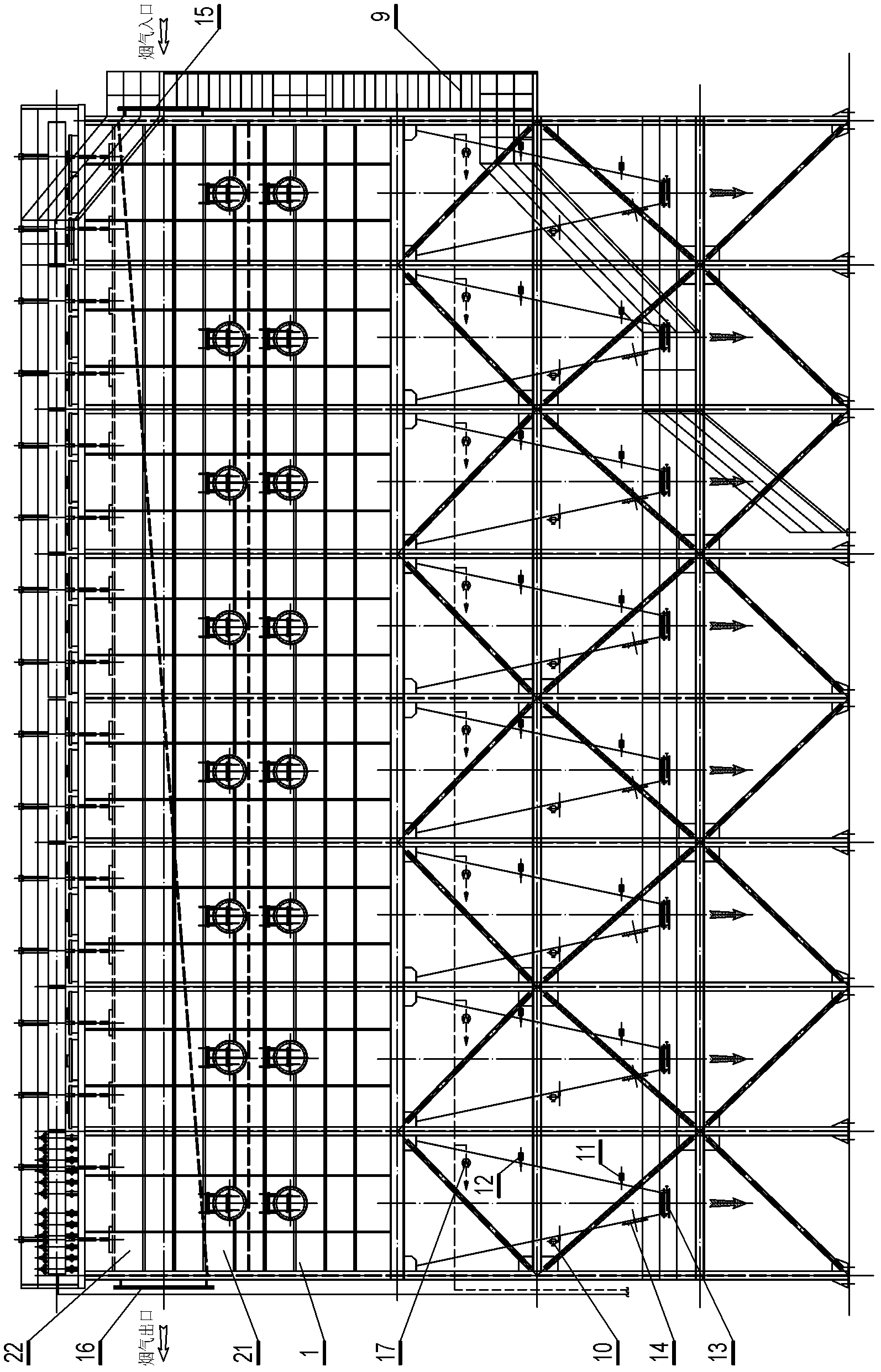

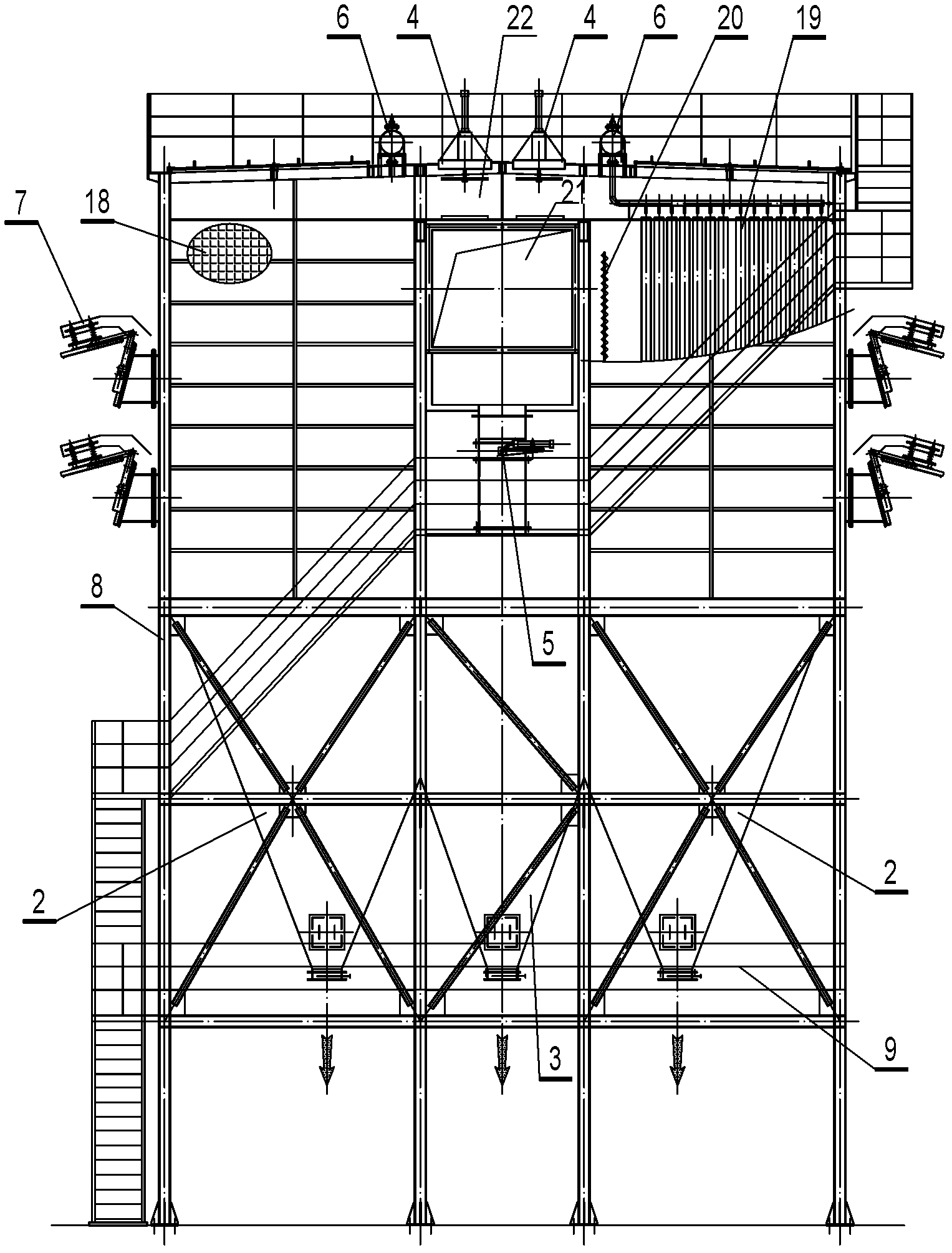

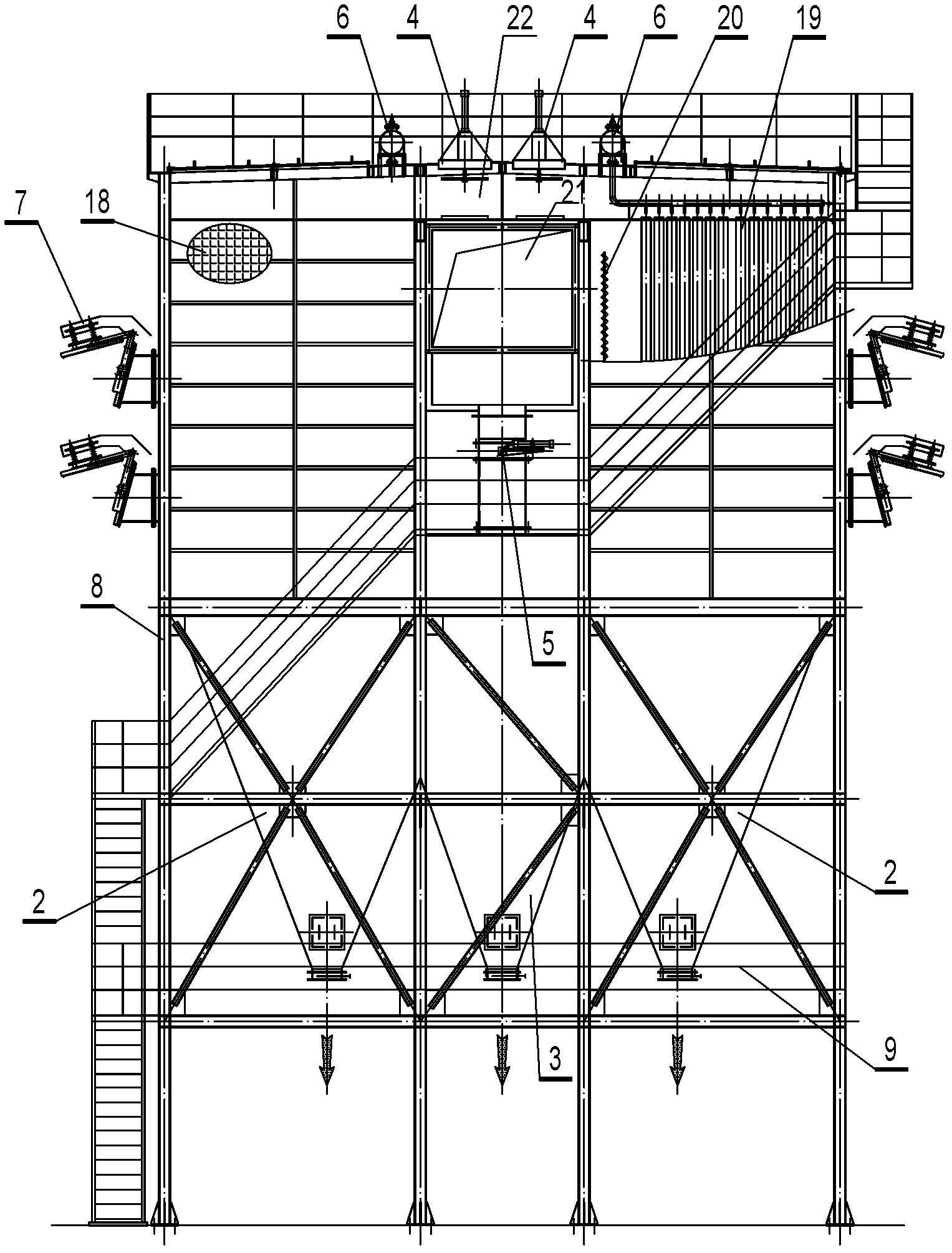

[0031] Below in conjunction with accompanying drawing, the present invention will be further described:

[0032] See figure 1 , figure 2 , fine particle coal recovery device, including two functional sections of coal pre-separation section and flue gas purification and discharge section, the separation efficiency of coal pre-separation section is very high, containing about 200g / Nm 3 After the flue gas of pulverized coal is separated by the coal pre-separation section, the concentration of pulverized coal can be reduced to 15-25g / Nm 3 . The flue gas purification and discharge section uses cloth bags as filter materials, and uses compressed nitrogen pulse injection as a means of cleaning dust.

[0033] Both the coal material pre-separation section and the flue gas purification and discharge section are box structures with an ash bin at the bottom. The coal material pre-separation section is equipped with an air inlet static pressure box 21, and the bottom is a coal materia

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap