Pipe coiling machine and engineering machine with pipe coiling machine

A technology of engineering machinery and hose reels, which is applied in earth movers/excavators, construction, etc., can solve the problems of high processing cost and assembly cost, increase system instability factors, and increase maintenance cost of seals, etc., to achieve Effects of enhancing stability, reducing cost, and simplifying system structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

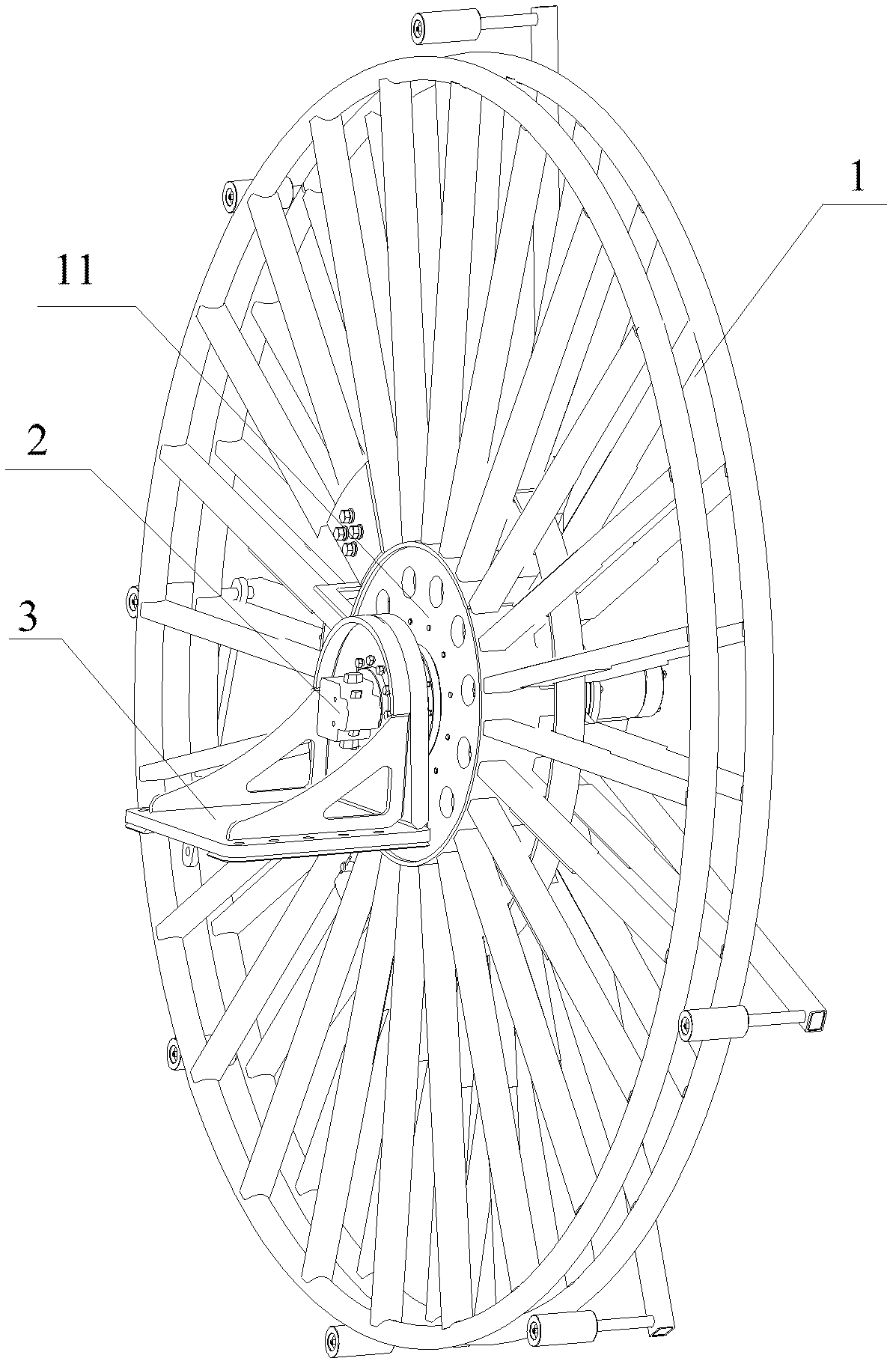

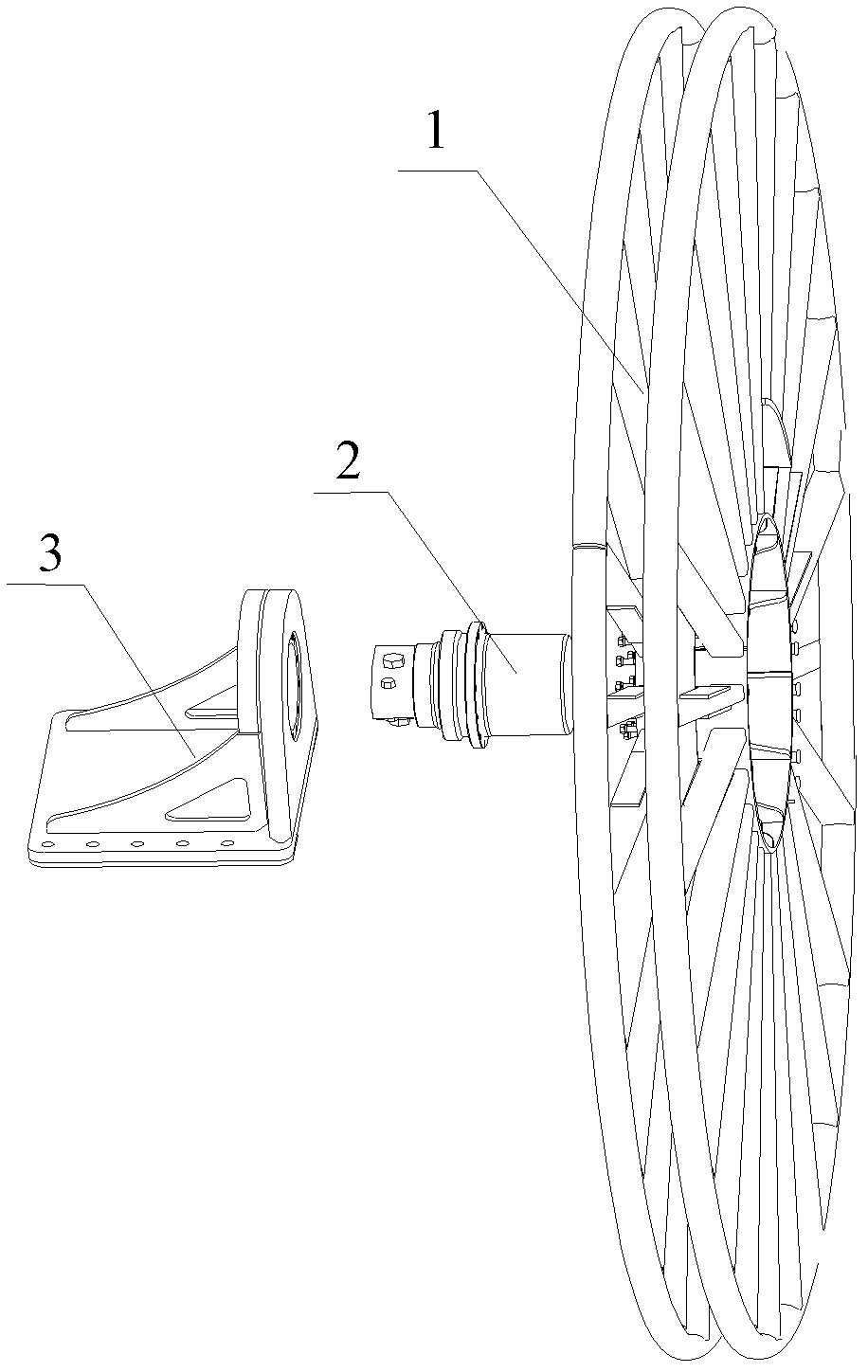

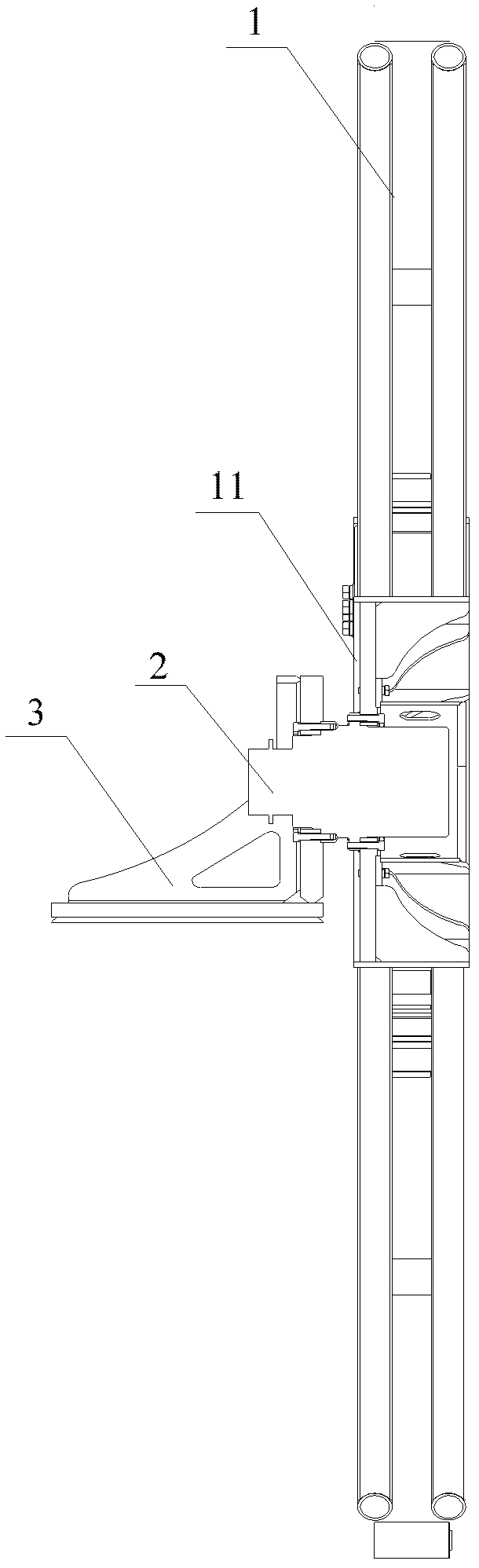

[0029] see figure 1 , figure 2 , figure 1 It is a perspective view of an embodiment of the hose reel of the present invention, figure 2 It is an exploded view of the embodiment of the hose reel of the present invention.

[0030] As shown in the figure, this embodiment of the hose reel includes a mounting base 3 , a power device 2 and a reel 1 . Wherein, the power device 2 is installed on the mounting seat 3, and the output flange of the power device 2 is connected with the reel flange 11 of the reel 1 to drive the reel 1 to rotate. At the same time, the power device 2 can bear a relatively large radial force, and is used to support the reel 1 and bear the gravity of the reel 1 without additional radial support system.

[0031] Preferably, the power unit 2 is a travel reducer, and its structure is as follows Figure 4 As shown, it includes a first mounting flange 21A and a first output flange 22A, the first mounting flange 21A is connected to the mounting seat 3, and the fi

Embodiment 2

[0039] see Figure 7 , Figure 8 , Figure 7 It is a structural schematic diagram of the wheel motor of the present invention; Figure 8 It is an axial sectional view of another embodiment of the hose reel of the present invention.

[0040] As shown in the figure, this embodiment includes a mount 3 , a power unit 2 and a reel 1 . Wherein, the power device 2 is installed on the mounting seat 3, and the output flange of the power device 2 is connected with the reel flange 11 of the reel 1 to drive the reel 1 to rotate. At the same time, the power device 2 can bear a relatively large radial force, and is used to support the reel 1 and bear the gravity of the reel 1 without additional radial support system.

[0041] The power unit 2 in this embodiment is a wheel motor. The structure of the wheel motor see Figure 7 , including a second mounting flange 21B and a second output flange 22B. The second mounting flange 21B is connected with the mounting seat 3 through bolts. A reel

Embodiment 3

[0047] The present invention also proposes a construction machine, which has the hose reel described in any one of the above items.

[0048] Preferably, the construction machine is a diaphragm wall grab groover, and the hose reel controls the hydraulic hose in the diaphragm wall grab groover to retract freely.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap