Method for extracting fulvic acid from sugar cane deep processing alcohol slops

A technology for deep processing of alcohol waste liquid, applied in botany equipment and methods, chemicals for biological control, animal repellants, etc., can solve problems such as not overcoming the technical problems of fulvic acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

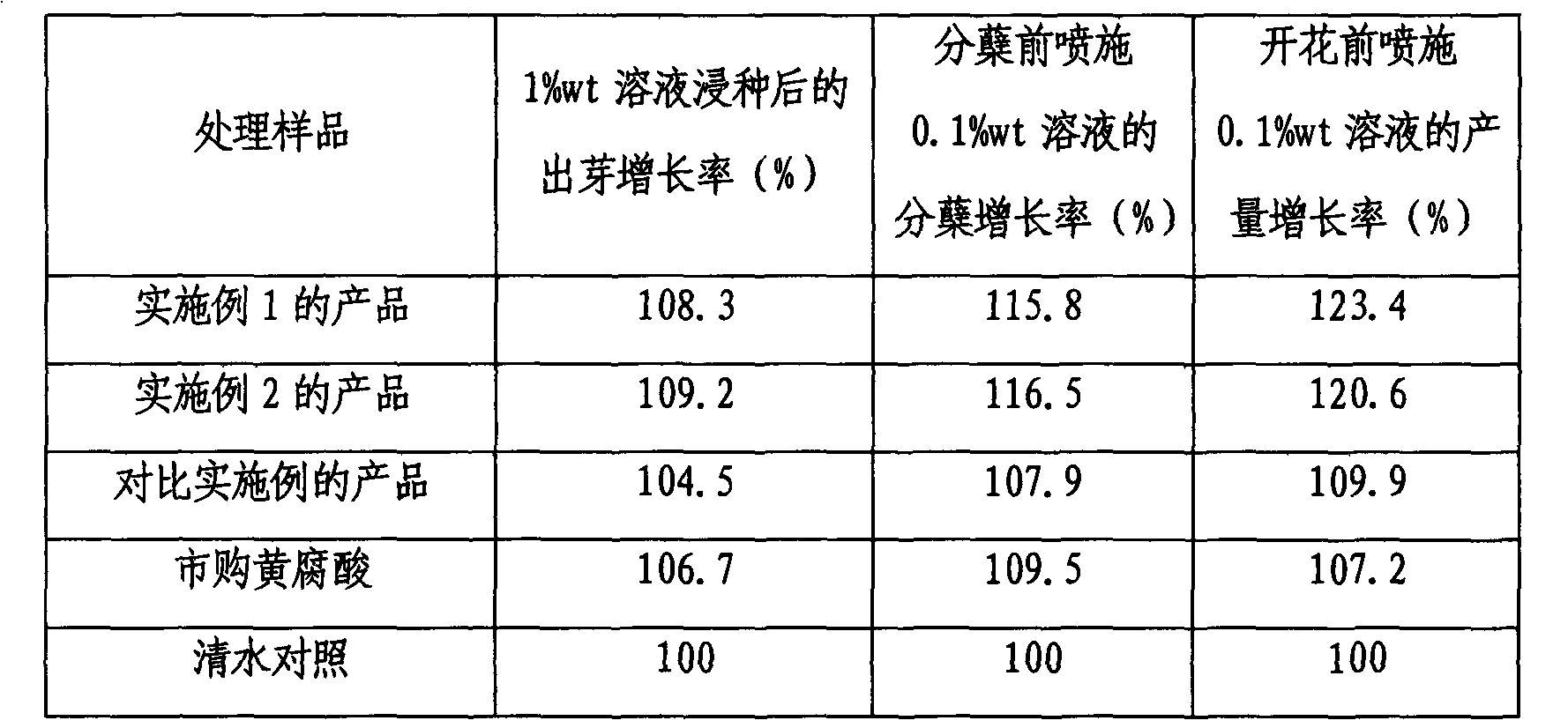

Examples

Embodiment 1

[0023] Concentrate 1 kg of alcohol waste liquid by heating under reduced pressure, evaporating and concentrating, controlling the pressure, and the evaporation temperature is 45°C±3°C. Stop heating when the weight percentage of dry matter in the concentrated liquid reaches 50%, and obtain a concentrated liquid; stir the liquid at a constant speed during the heating process. Then add concentrated sulfuric acid to the concentrated solution to make the mass concentration of sulfuric acid in the concentrated solution reach 30%, and age at 60±2°C for 20 hours to obtain an aged solution;

[0024] Alkaline the aged liquid with 1%wt sodium hydroxide solution, add the sodium hydroxide solution under stirring, measure the pH of the solution, adjust the addition amount of the sodium hydroxide solution, stop adding the sodium hydroxide solution when the pH is 9 , precipitation occurs in the solution, and the precipitated part is removed by filtration to obtain solution I;

[0025] The soluti

Embodiment 2

[0029] Concentrate 1 kg of alcohol waste liquid by heating under reduced pressure, evaporating and concentrating, controlling the pressure, and the evaporation temperature is 40°C±3°C. Stop heating when the weight percentage of dry matter in the concentrated liquid reaches 60%, and obtain a concentrated liquid; stir the liquid at a constant speed during the heating process. Then add concentrated sulfuric acid to the concentrated solution to make the mass concentration of sulfuric acid in the concentrated solution reach 30%, and age at 60±2°C for 20 hours to obtain an aged solution;

[0030] Alkaline the aging liquid with 0.5%wt sodium hydroxide solution, add sodium hydroxide solution under stirring, measure the pH of the solution, adjust the amount of sodium hydroxide solution added, stop adding sodium hydroxide solution when the pH is 8 , precipitation occurs in the solution, and the precipitated part is removed by filtration to obtain solution I;

[0031] The solution I obtaine

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap