Barium-tungsten cathode with high current density and preparation method of cathode

A barium tungsten cathode and high current technology, which is applied in the field of barium tungsten cathode with high current density and its preparation, can solve the problems of low barium content of cathode active material, inability to work stably for a long time, uneven pore structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

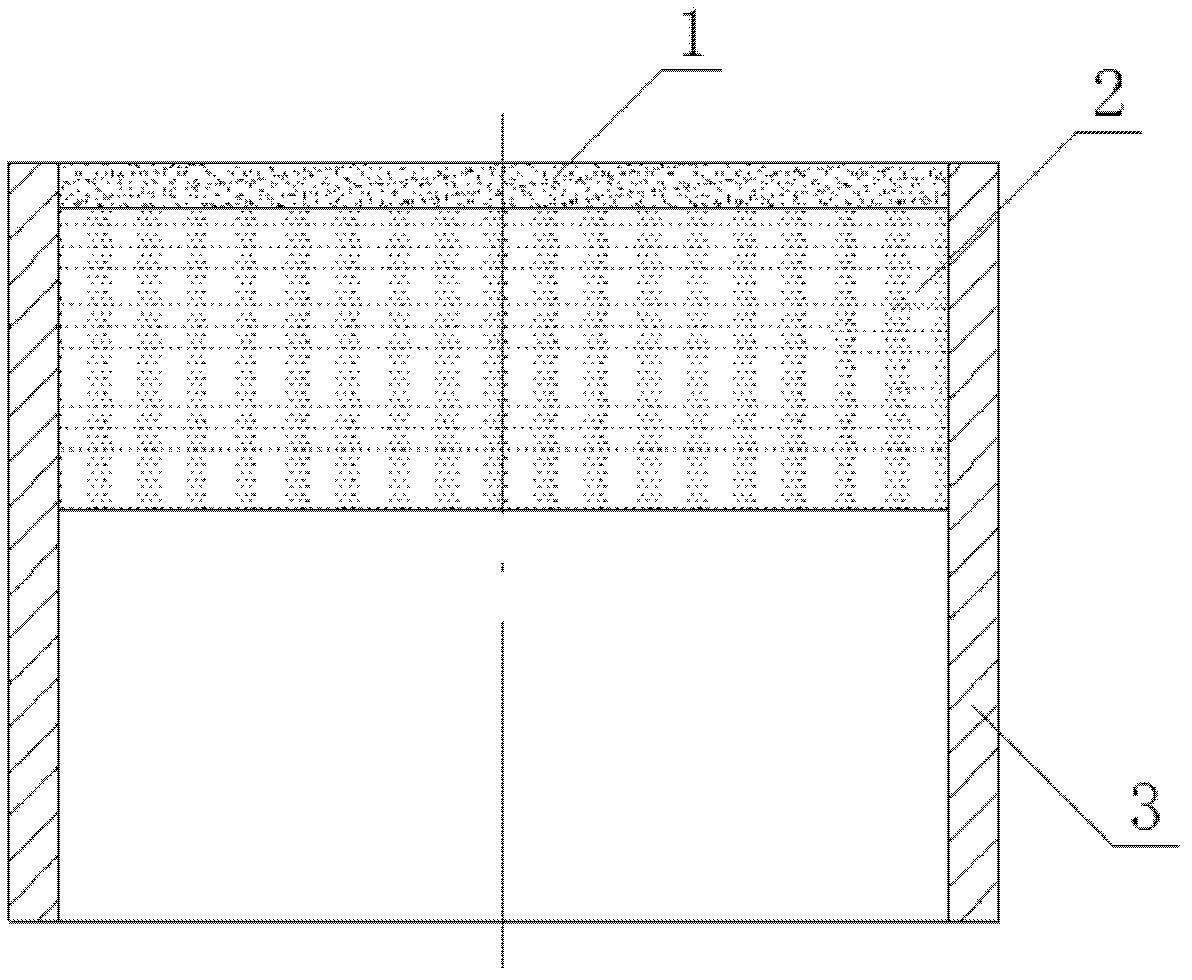

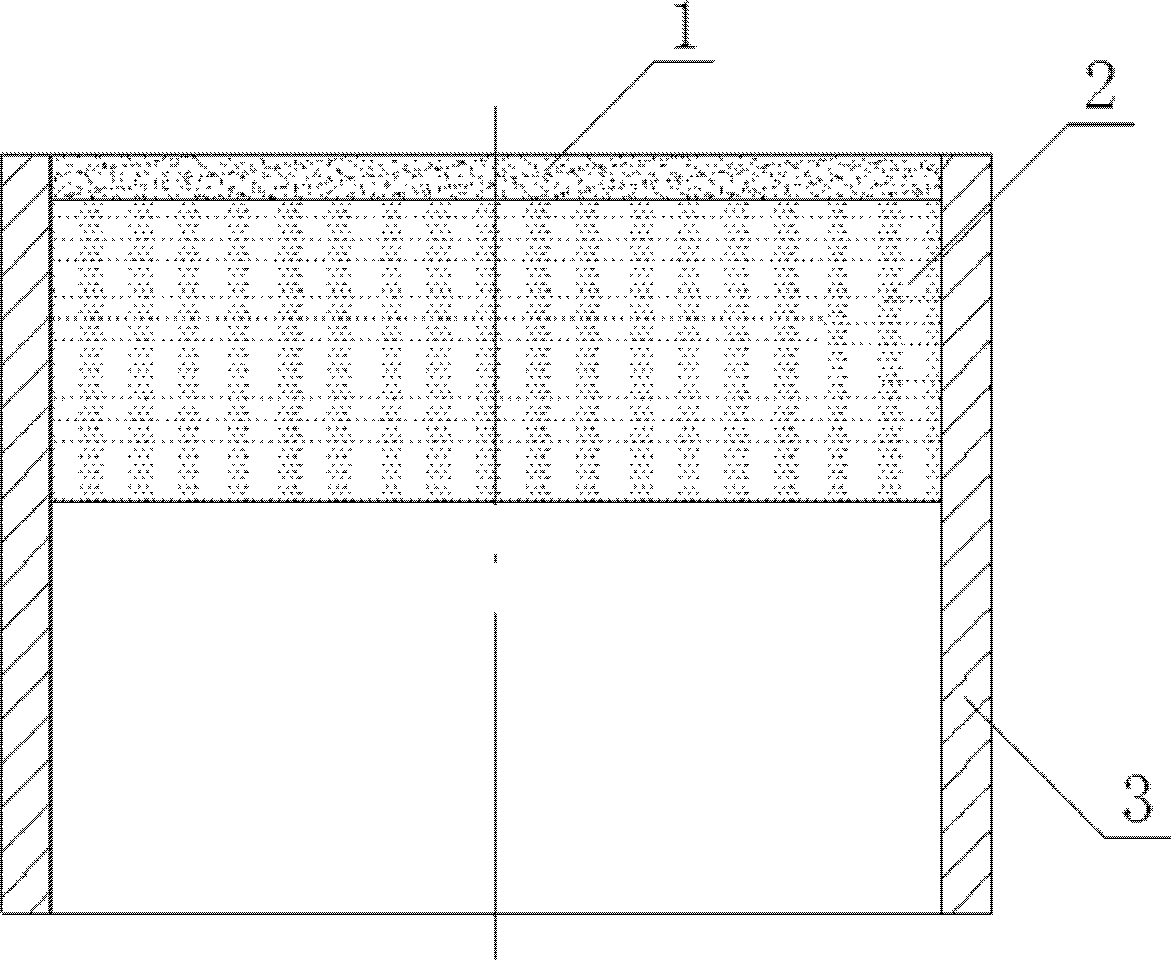

[0022] figure 1 Shown is the structure schematic diagram of barium tungsten cathode in the present invention, the barium tungsten cathode of this kind of high current density comprises cathode molybdenum cylinder 3 and the double-layer substrate that is filled in cathode molybdenum cylinder 3, and double-layer substrate comprises upper layer and lower layer, and upper layer is The spherical tungsten powder layer 1 is formed by pressing spherical tungsten powder as the base material, and the lower layer is a tungsten-rhenium alloy layer 2 formed by pressing tungsten powder and rhenium powder as the base material.

[0023] The particle size of the spherical tungsten powder in the upper spherical tungsten powder layer 1 is 2 μm to 10 μm, preferably 4 μm; the tungsten powder and rhenium powder in the lower tungsten-rhenium alloy layer 2 are mixed according to the ratio of 10% to 50%: 90% to 50%. Evenly, the proportioning ratio is preferably 20%:80%.

[0024] A method for preparing a

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap