Detachable anti-loosing and anti-theft bolt structure

A technology of anti-theft bolts and bolts, applied in the direction of bolts, screws, nuts, etc., can solve the problems of difficult processing, high cost, complex structure, etc., and achieve the effects of avoiding destructive disassembly, high anti-theft and anti-theft, and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

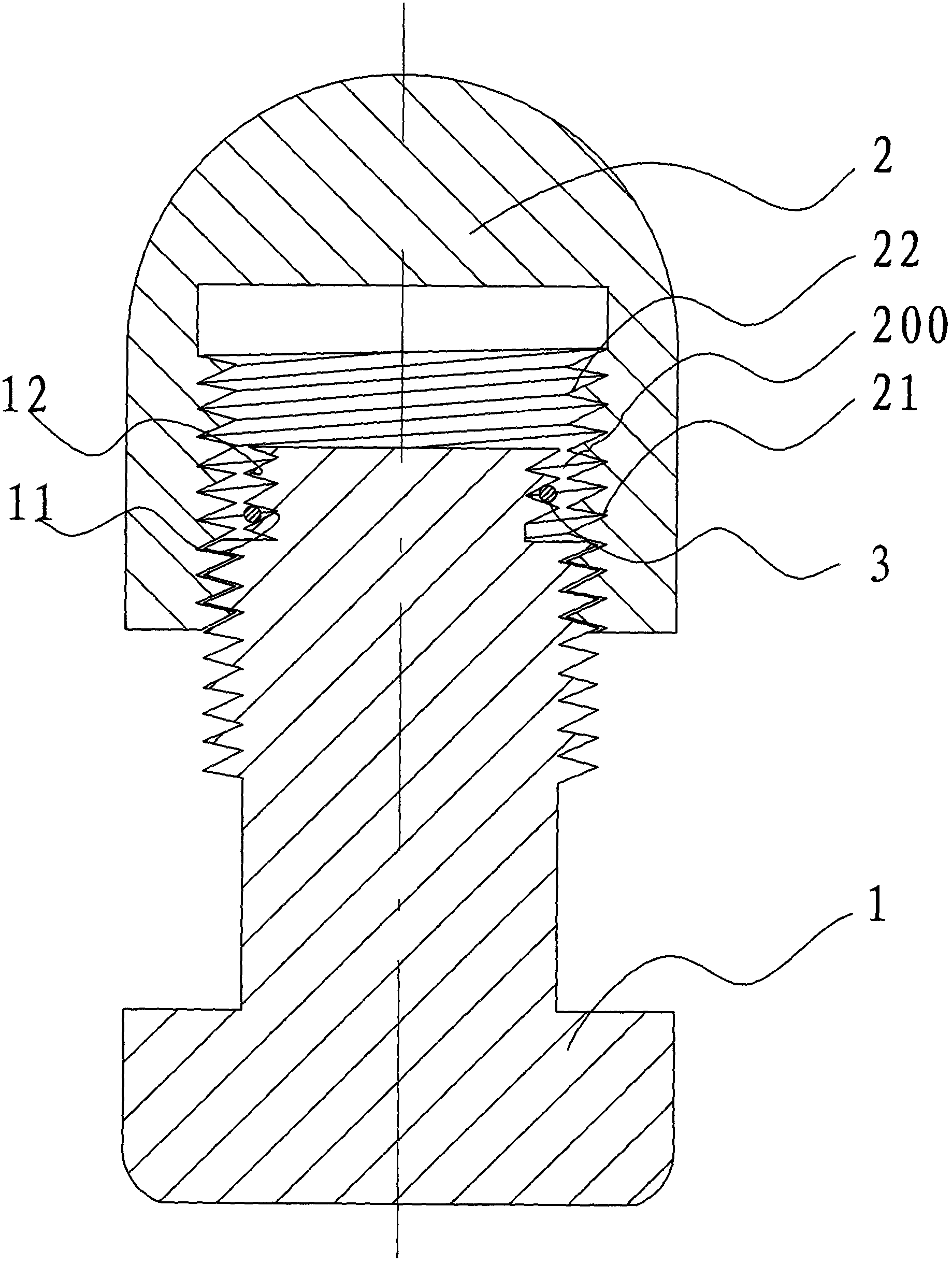

[0015] With reference to accompanying drawing, the thickness of nut 2 of the present invention should be greater than the length of bolt lower section, to reserve several circles of internal threads at the upper end to correspond to the upper section external thread of bolt, for locking purposes. The head of the standard part bolt 1 is processed with a machine tool to reduce the diameter, and the diameter reduction is slightly larger than the thread depth of the screw thread, so as not to contact with the screw thread of the nut when extending into the nut. The reduced-diameter section is called the upper section, and the non-shrinked-diameter section is called the lower section. The length of the upper section is preferably 1-3 pitches, and the lower section is a fastening function section that cooperates with the nut thread. First stagger half the pitch in the upper section to process 1-3 turns of thread, and the threads in the upper and lower sections are the same. In this way,

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap