Binary synchronization electromagnetic block brake of gantry

An electromagnetic block and brake technology, applied in drum brakes, brake types, axial brakes, etc., can solve problems such as inconvenience and brake loss gap adjustment, and achieve enhanced autonomy, improved work reliability, and reasonable force. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

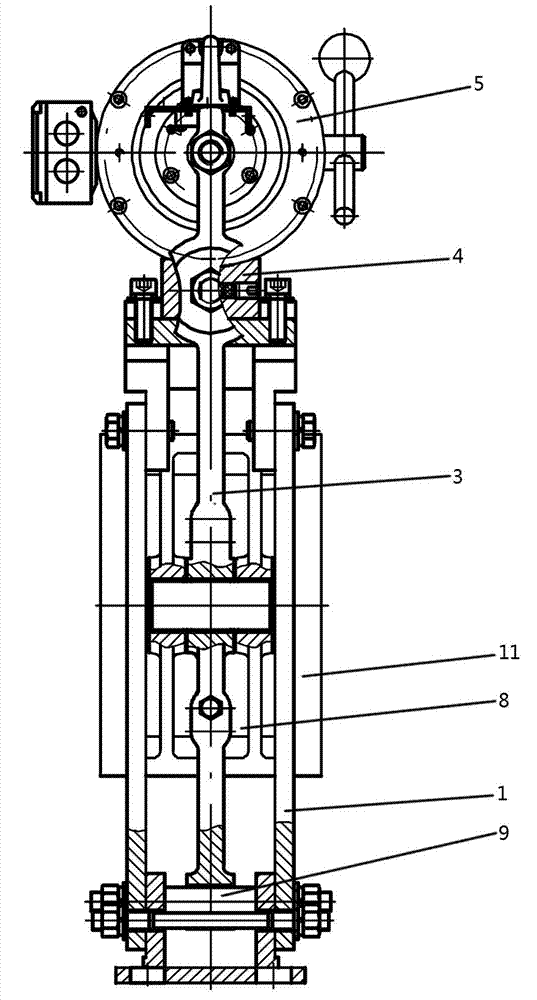

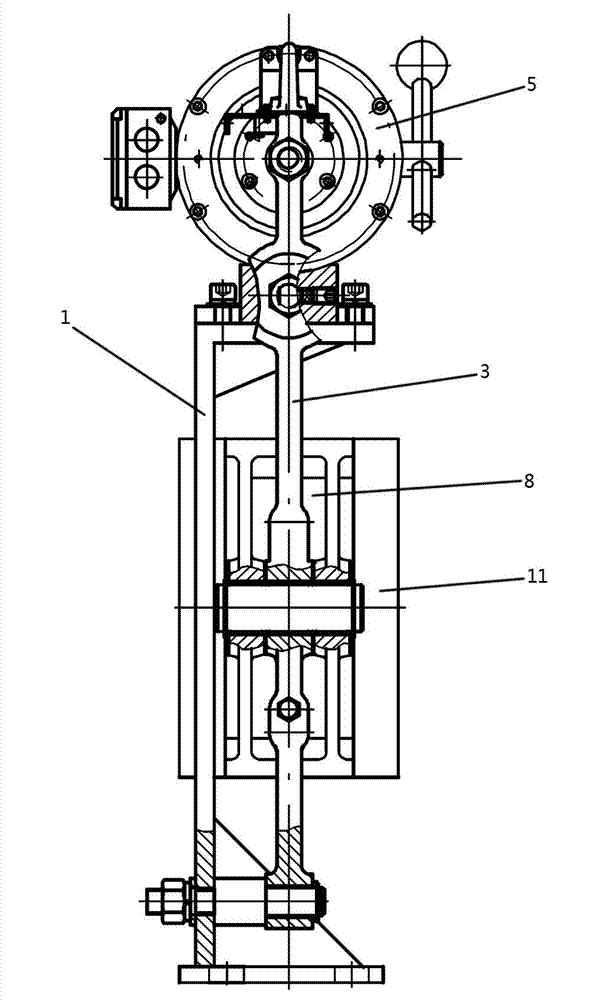

[0028] Such as figure 1 , figure 2 As shown, the gantry support 1 is a rectangular frame structure fixedly connected by a side frame, a top beam and a base. The two side frames are composed of two long strip-shaped vertical panels facing each other ( figure 2 ), the lower ends of the two vertical plates are fixedly connected to the base by bolts, and the upper ends of the two vertical plates are fixedly connected to the top beam by bolts.

[0029] A brake arm 3 is respectively connected to both sides of the gantry support 1 . The brake arm 3 is located between the two long vertical plates of the side frame, and the hinge shaft 9 passes through the two vertical plates of the side frame and the lower end of the brake arm 3 to realize the connection between the brake arm 3 and the gantry bracket 1. (Of course, the brake arm 3 can also be hinged on the base of the gantry support 1). The middle part of the brake arm 3 is connected with the inward brake shoe 8 in a conventional m

Embodiment 2

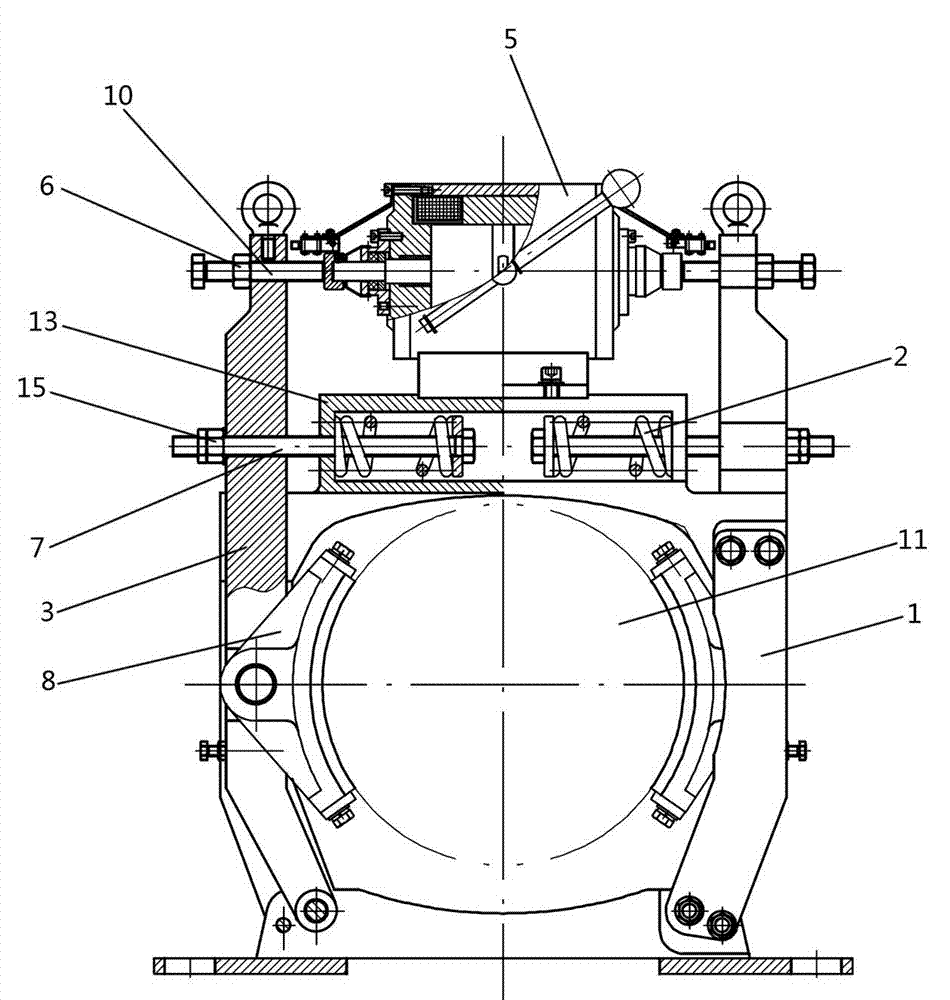

[0038] Such as figure 1 , image 3As shown, the basic structure of the present embodiment is the same as that of Embodiment 1, that is, the gantry support 1 is a rectangular frame fixedly connected by the side frame, the top beam and the base, and the double push electromagnet 5 is fixed on the top beam of the gantry support 1 , brake arms 3 are respectively hinged on both sides of the gantry bracket 1, and brake shoes 8 are connected to the brake arms 3. The concave arc surfaces of the two brake shoes 8 are opposite to the outer circle of the brake wheel 11. A pull rod 7 is connected to the upper end of each brake arm 3, and a brake spring 2 is sleeved on the pull rod 7. The gap adjusting mechanism is an adjusting screw 10 threadedly connected with a transverse screw hole on the brake arm 3 , and is locked on the brake arm 3 by a lock nut 6 .

[0039] The main difference of this embodiment is that a gantry support structure supported by a single plate surface is adopted, that

Embodiment 3

[0041] Such as Figure 4 As shown, the basic structure of the present embodiment is the same as that of Embodiment 1, that is, the gantry support 1 is a rectangular frame that is fixedly connected by the side frame, the top beam and the base, and the double push electromagnet 5 is fixed on the top beam of the gantry support 1, Brake arms 3 are respectively hinged on both sides of the gantry support 1, and brake shoes 8 are connected to the brake arms 3. The concave arc surfaces of the two brake shoes 8 are opposite to the outer circle of the brake wheel 11. The gap adjustment mechanism in this embodiment is an adjusting screw 10 threadedly connected with the transverse screw hole on the brake arm 3, locked on the brake arm 3 by the lock nut 6, and its inner end is against the double-push electromagnet. 5 on the end face (or sheath) of the output shaft.

[0042] The main difference of this embodiment is that the brake spring 2 is changed from an external to a built-in structure,

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap