High-pressure micro-jet carbon supplementing system for microalgae cultivation of raceway pond

A high-pressure micro-spray and runway pool technology, applied in the field of bioengineering, can solve problems such as algae liquid damage and blockage, and achieve the effect of reducing damage, ensuring normal operation, and avoiding blockage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

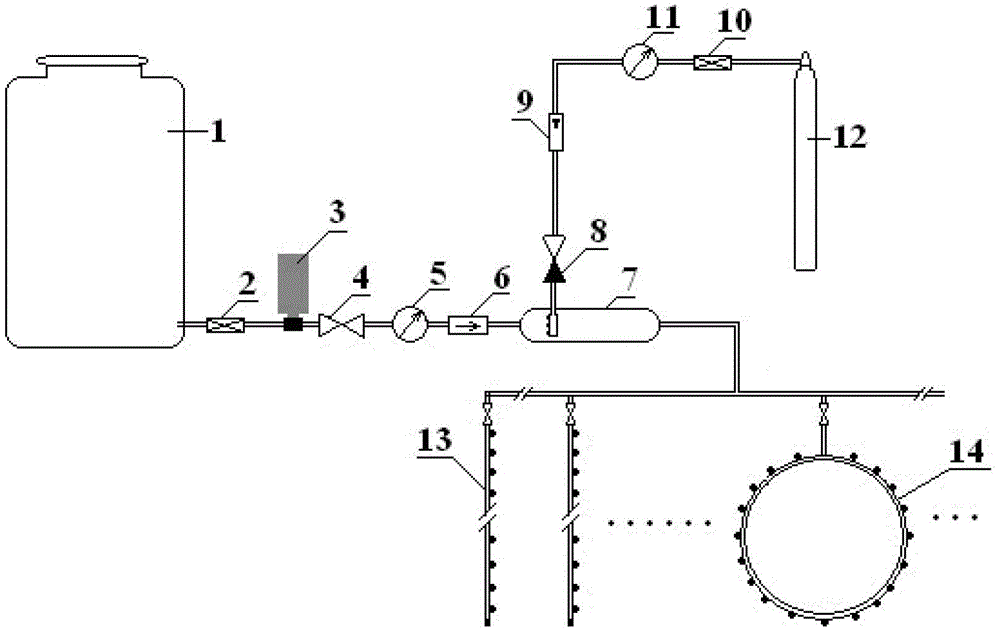

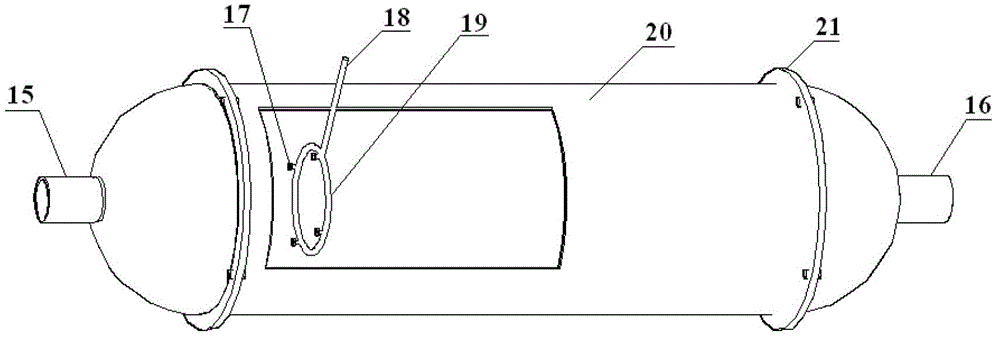

[0028] Such as figure 1 with figure 2 As shown, the high-pressure micro-spraying carbon system for cultivating microalgae in the raceway pond includes a liquid part that provides high-pressure liquid, a high-pressure CO 2 The gas part, the high-pressure micro-spray device 7 and the micro-spray head group. Described high-pressure micro-spray device 7 comprises device housing 20, liquid inlet 15, several micro-spray nozzles 17, gas inlet 18, nozzle disc 19, liquid outlet 16, and housing 20 is metal material or organic material, and its two ends semicircle structure and The intermediate barrel structure is connected by flange 21; the high-pressure liquid enters the high-pressure micro-spray device 7 through the liquid inlet 15 and the CO sprayed by the micro-spray head 17 on the head plate 19. 2 The gas is reversely mixed with the two phases, and the formed fully dissolved CO 2 The liquid enters the micro-spray head group through the liquid outlet 16; the micro-spray head group

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap