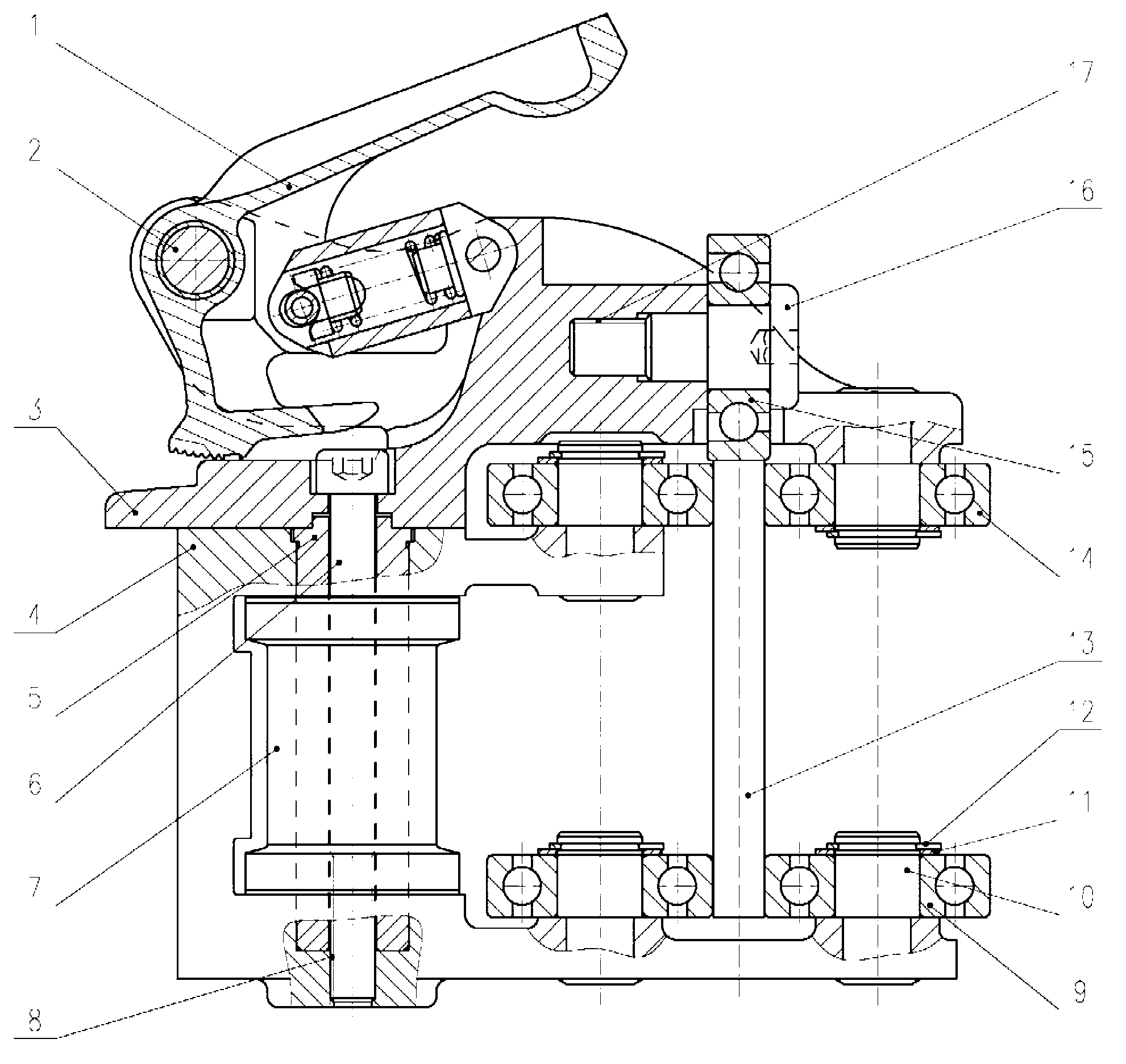

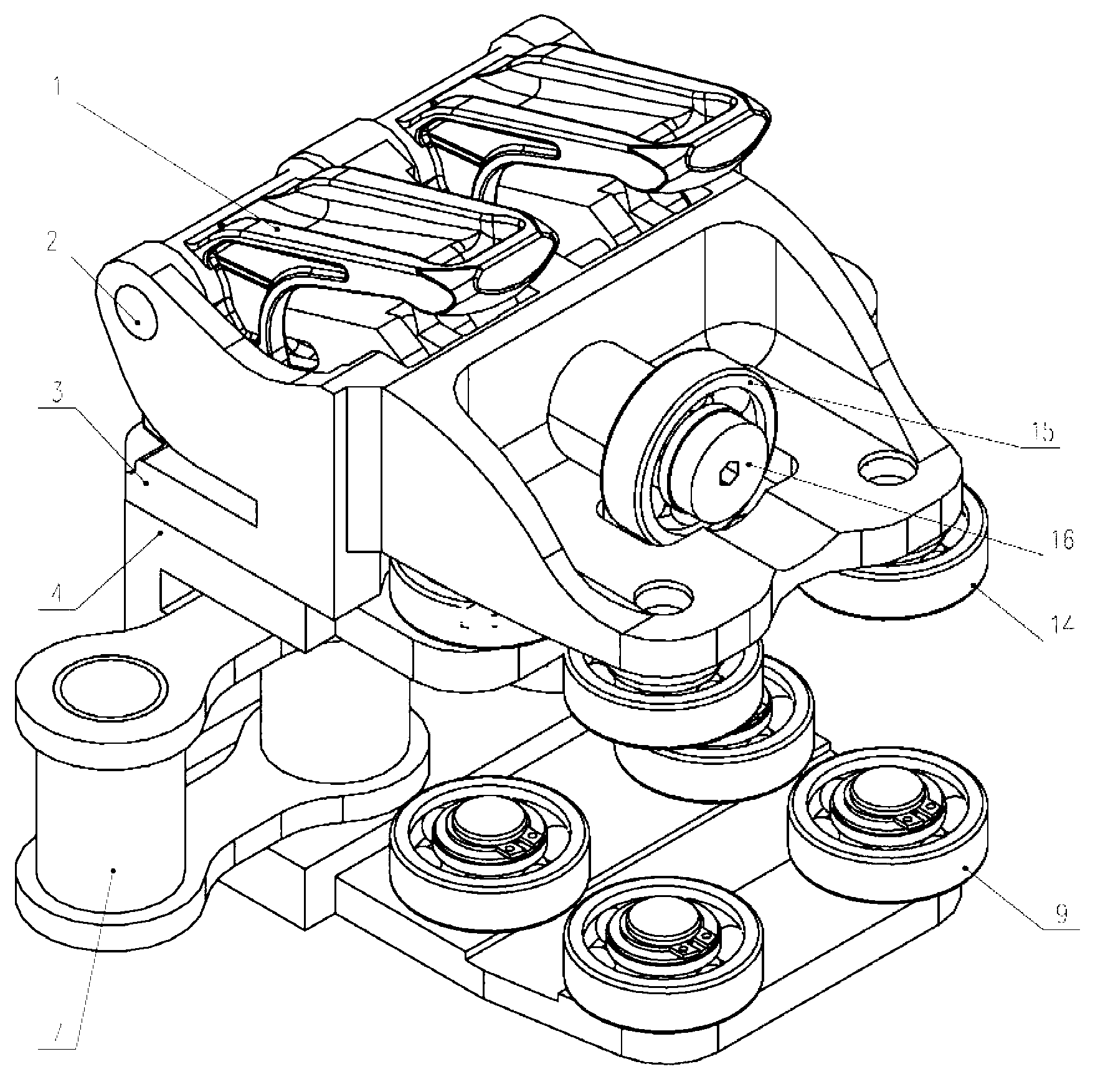

Chain tongs structure of thin film stretching production line

A technology of production line and chain clamp, which is applied in the field of chain clamp structure of film stretching production line, can solve the problems of affecting the service life of guide rail and easy wear of contact surface, and achieve the effect of easy disassembly, small friction coefficient and reduced friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0021] Example of chain clamp structure of this film stretching production line figure 1 As shown, the clamp body is divided into two independent parts: the upper clamp body 3 and the support base 4. The clamp handle 1 is rotatably installed on the upper clamp body 3 via the long shaft 2. The supporting base 4 has an upper plate and a lower plate. The upper clamp body 3 is located above the supporting base 4 and the two are fixedly connected by a positioning pin 5 and a long screw 6. The upper end of the positioning pin 5 with a central hole is connected to the upper clamp body 3, passes through the upper plate of the support base 4, and the lower end is matched with the lower plate. The long screw 6 is inserted into the center hole of the positioning pin 5 from the mounting hole of the upper clamp body 3, and the lower end is screwed into the threaded hole of the lower plate of the supporting seat 4, and the lower end is equipped with an anti-loosening sleeve 8. The chain link 7

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap