Power transmission device of rootstock excavator

A transmission device and mechanical power technology, applied in transmission devices, excavator harvesters, harvesters and other directions, can solve the problems of high maintenance cost, large energy consumption, large volume, etc., and achieve stable and reliable work, simple structure and high efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

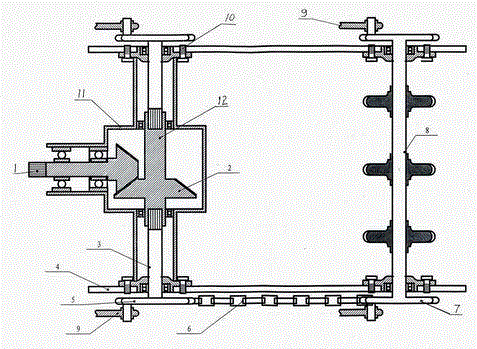

[0008] The embodiment is described in detail in conjunction with the above accompanying drawings. It includes two side beams 4 fixed to the body, a reduction box 11 is fixedly connected with a bolt 10 between the front ends of the two side beams, and a reduction box 11 is fixed between the two side beam rear ends. The bolt and the bearing seat are installed with an endless chain box transmission shaft 8, a pair of bridge sector gears 2 are installed in the reduction box, and a power input shaft 1 protruding forward is installed on the bridge sector gears at the front of the reduction box , a semi-floating half-shaft 3 is respectively connected to the output shafts 12 at both ends of the bridge-type sector gear at the back, and the outer ends of the two semi-floating half-shafts protrude from the reduction box through the bearing seat to the outside of the side beam respectively. A sprocket 5 is respectively installed on the outer end of each semi-floating half shaft, a rear sprock

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap