Single-mode fiber connector wire on basis of adhesive-free vitrification technology, related nanometer-sized silicon dioxide and manufacturing method

A technology of silica and single-mode optical fiber, which is applied in the field of optoelectronics, can solve the problem of no connector, etc., and achieve the effect of simple structure, suitable for large-scale promotion and application, and ingenious design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

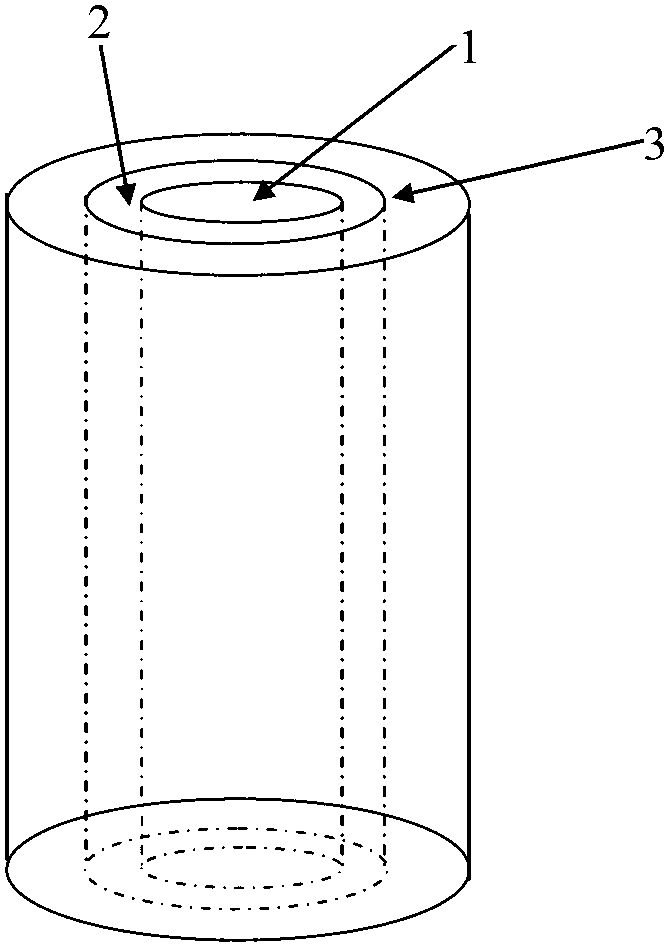

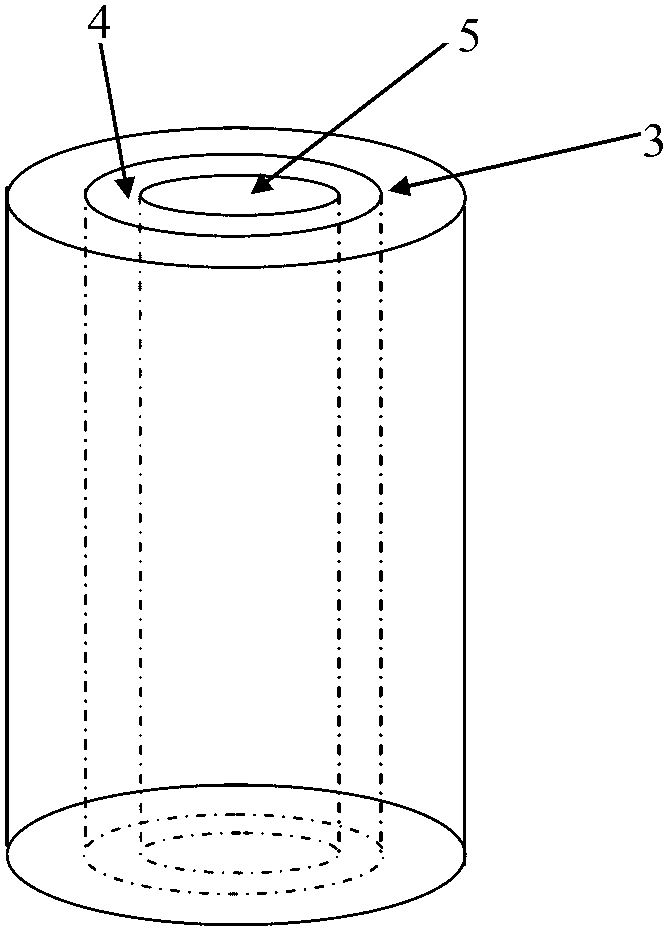

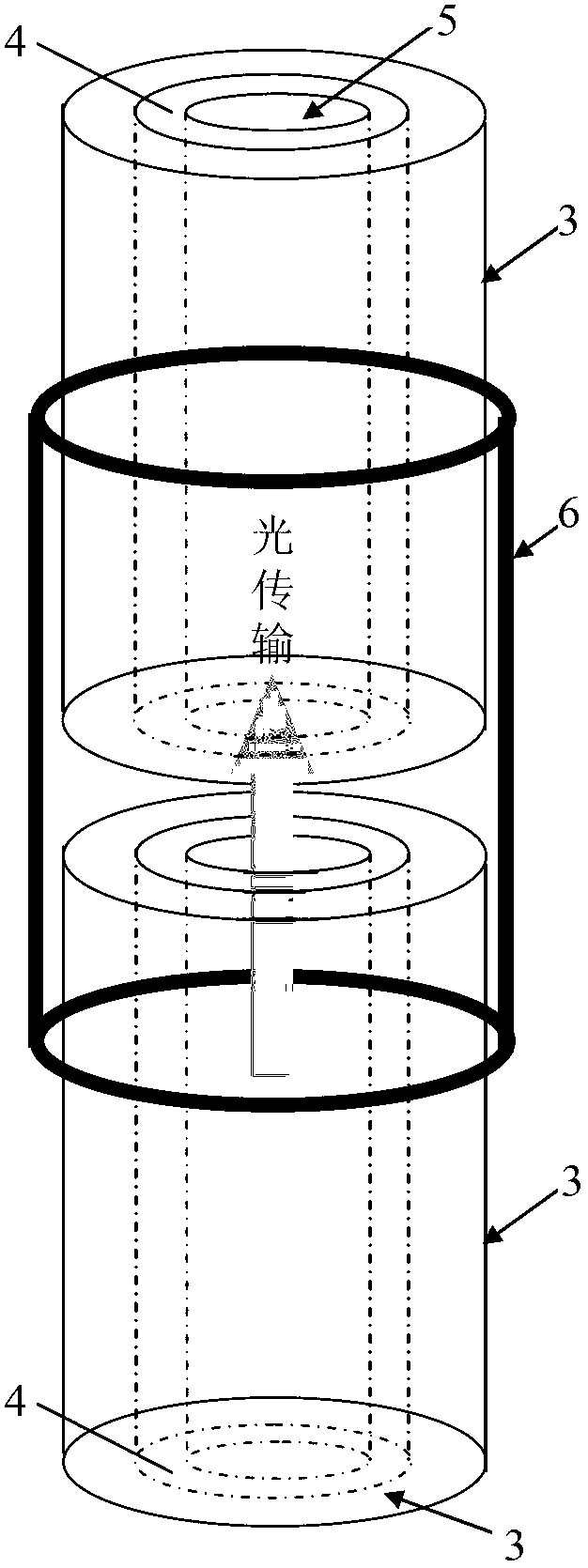

[0031] Insert a 125-micron silica fiber 5 with the coating removed in a ceramic ferrule with a pore size of 127 microns, and fill it with nano-scale SiO by vacuum technology 2 Mixed powder with Au (gold), the mixing ratio is 90:10, SiO 2 And the purity of Au is 99.9%, and the melting point is 1000°C. The preform was placed at 1100°C for 3 minutes and then cooled. Grinding after cooling, the grinding angle is 8 degrees (according to FC / APC requirements) and equipped with a fiber optic adapter with heat dissipation. Through 6W 1550nm single-mode laser (power density reaches 0.1W / μm 2 ), the loss is 0.28dB, after 20 times of plugging and unplugging with light, after 500 hours of long-term connection, the end face of the optical fiber is complete without any burning marks from the microscope.

Embodiment 2

[0033] Insert a 125-micron silica fiber 5 with the coating removed in a metal ferrule with an aperture of 127 microns, and fill it with nano-scale pure SiO by vacuum technology 2 powder, place the preform at 1700°C for 3 minutes and then cool. Grinding after cooling, the grinding angle is 8 degrees (according to FC / APC requirements) and equipped with a fiber optic adapter with heat dissipation. Through 6W 1550nm single-mode laser (power density reaches 0.1W / μm 2 ), the loss is 0.28dB, after 20 times of plugging and unplugging with light, after 500 hours of long-term connection, the end face of the optical fiber is complete without any burning marks from the microscope.

[0034] The basic principle of the present invention is: when making the single-mode optical fiber connector line based on glue-free vitrification technology, inject nano-scale low melting point SiO2 between the quartz optical fiber 5 and the ferrule 3 2 Powder, the preform is placed in a high temperature en

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap