Net mobile electrostatic precipitator of dust collecting electrode, and dust collecting method

A technology of electrostatic precipitator and dust collector, which is applied in the direction of external electrostatic separator, electrode structure, electrostatic separation, etc., can solve the problems of large investment, difficult to capture, long construction period, etc., to achieve enhanced dust removal effect and high capture rate, avoid the effect of secondary flying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

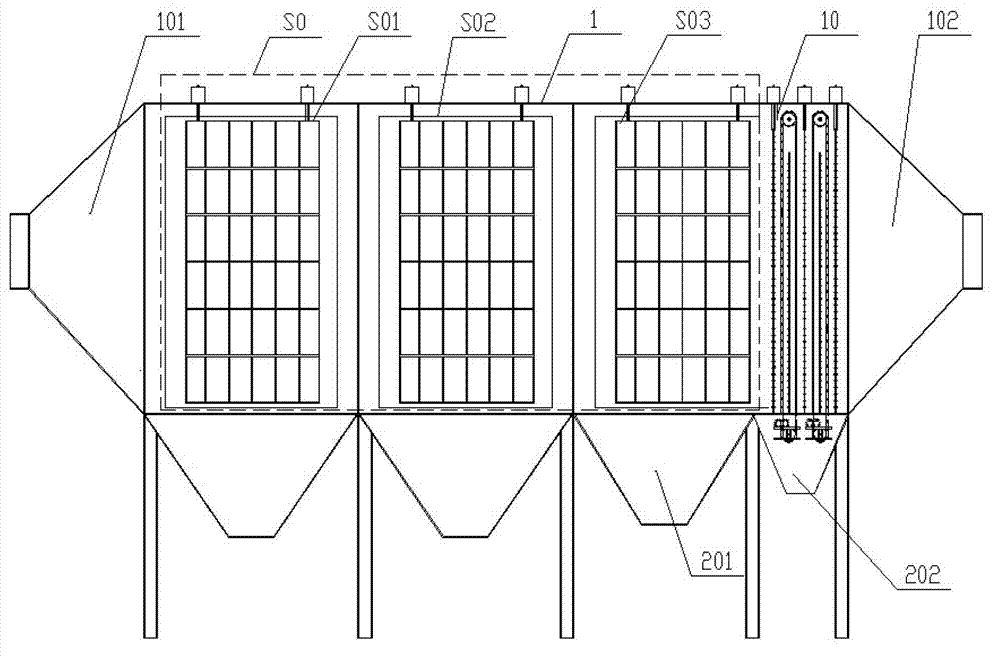

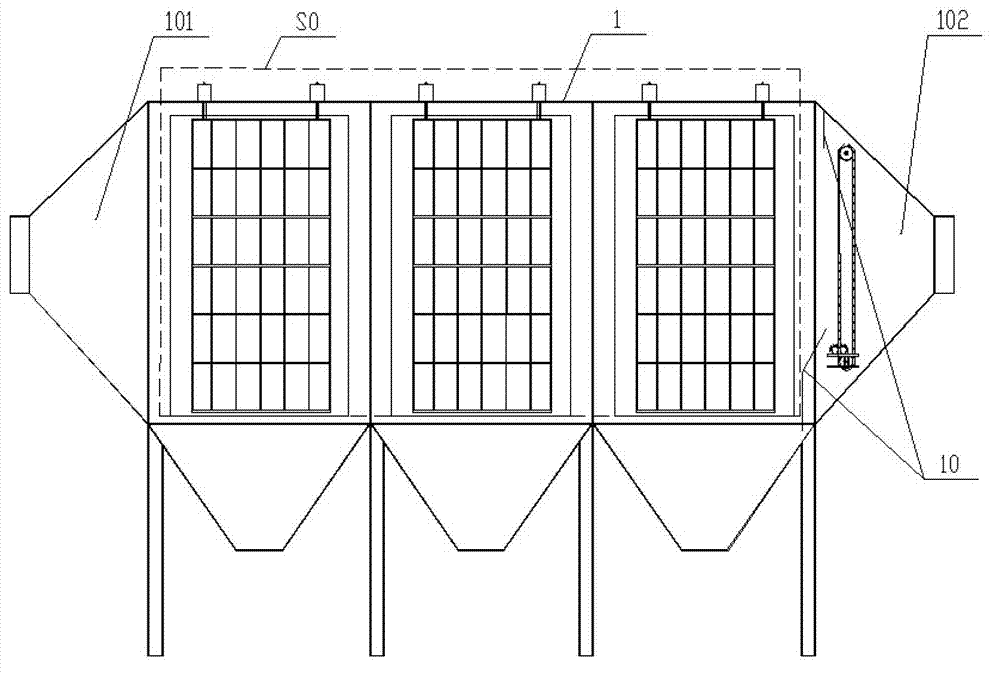

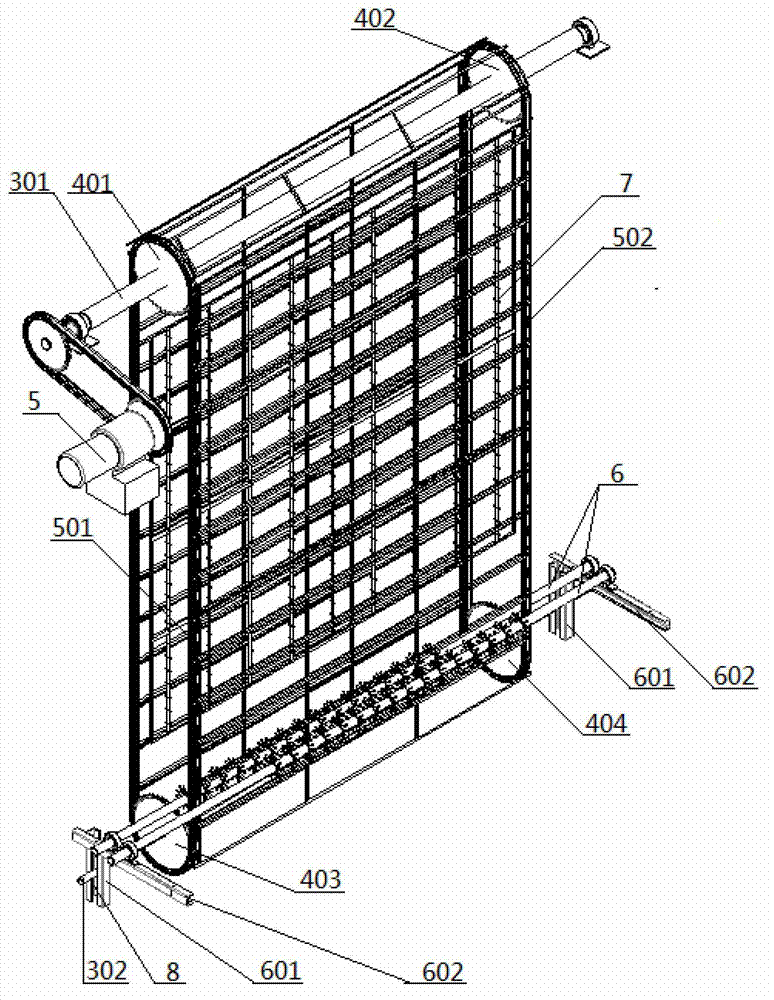

[0041] see figure 1 , 3 -7. An electrostatic precipitator with mesh mobile dust collector provided in the embodiment of the present invention, comprising: an air inlet 101 for airflow input, an air outlet 102 for airflow output, a dust collection device, and a first ash hopper 201 and housing 1. Wherein, the air inlet 101 is placed at one end of the casing 1, and the gas outlet 102 is placed at the other end of the casing 1. The casing 1 is provided with a cathode wire and an anode plate for generating the first electric field S0 (the cathode wire is charged with a negative high voltage , the anode plate is grounded). The first ash hopper 201 is placed under the first electric field S0. At the same time, a dust adsorption device for generating the second electric field is also provided behind the first electric field S0 (inside the end of the housing 1 near the air outlet 102 ).

[0042] In the first embodiment, the dust adsorption device includes: a mesh dust collector for a

Embodiment 2

[0056] see Figure 2-7 , the second embodiment provides another net mobile dust collector electrostatic precipitator. This embodiment 2 is aimed at the electrostatic precipitator technology in embodiment 1, by changing the location of the dust adsorption device, that is, adding at least one set of dust adsorption device in the air outlet 102, including rotating shafts 301-302, sprockets 401-404, and chains 501-502. And the connection relationship of each component is the same as that in the first embodiment. At the same time, a baffle 10 is added to the lower part of the dust adsorption device, so that the rotating dust cleaning brush is located in the non-air flow area. The rest of the settings are the same as in Embodiment 1.

[0057] In Embodiment 1 and Embodiment 2 provided by the present invention, when the lateral width of the housing 1 is too large (that is, a set of mesh dust collectors cannot block the air flow area), two (or more) dust adsorption devices can be used

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap