Key structure

A button and fixed structure technology, applied to electrical components, electric switches, circuits, etc., can solve the problems of poor injection molding of L”-shaped elastic belts, easy damage to transportation and assembly, etc., and achieve the effect of reducing the number of mold revisions and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

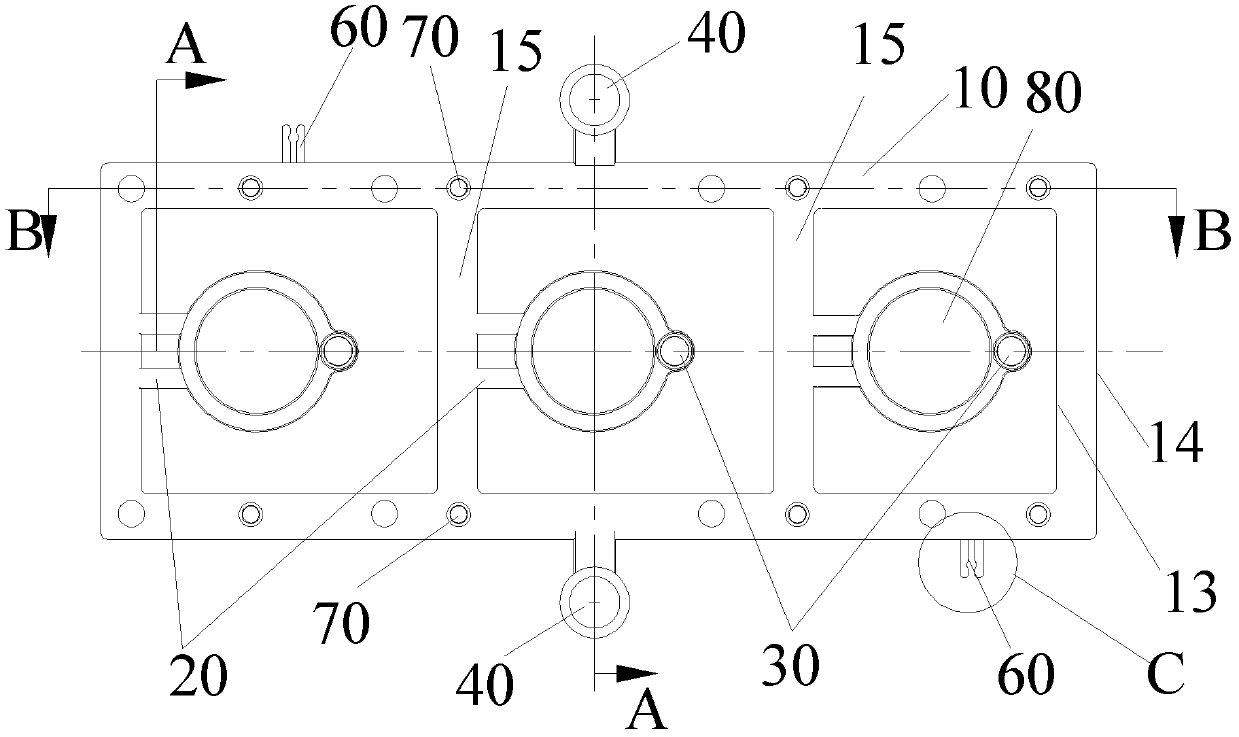

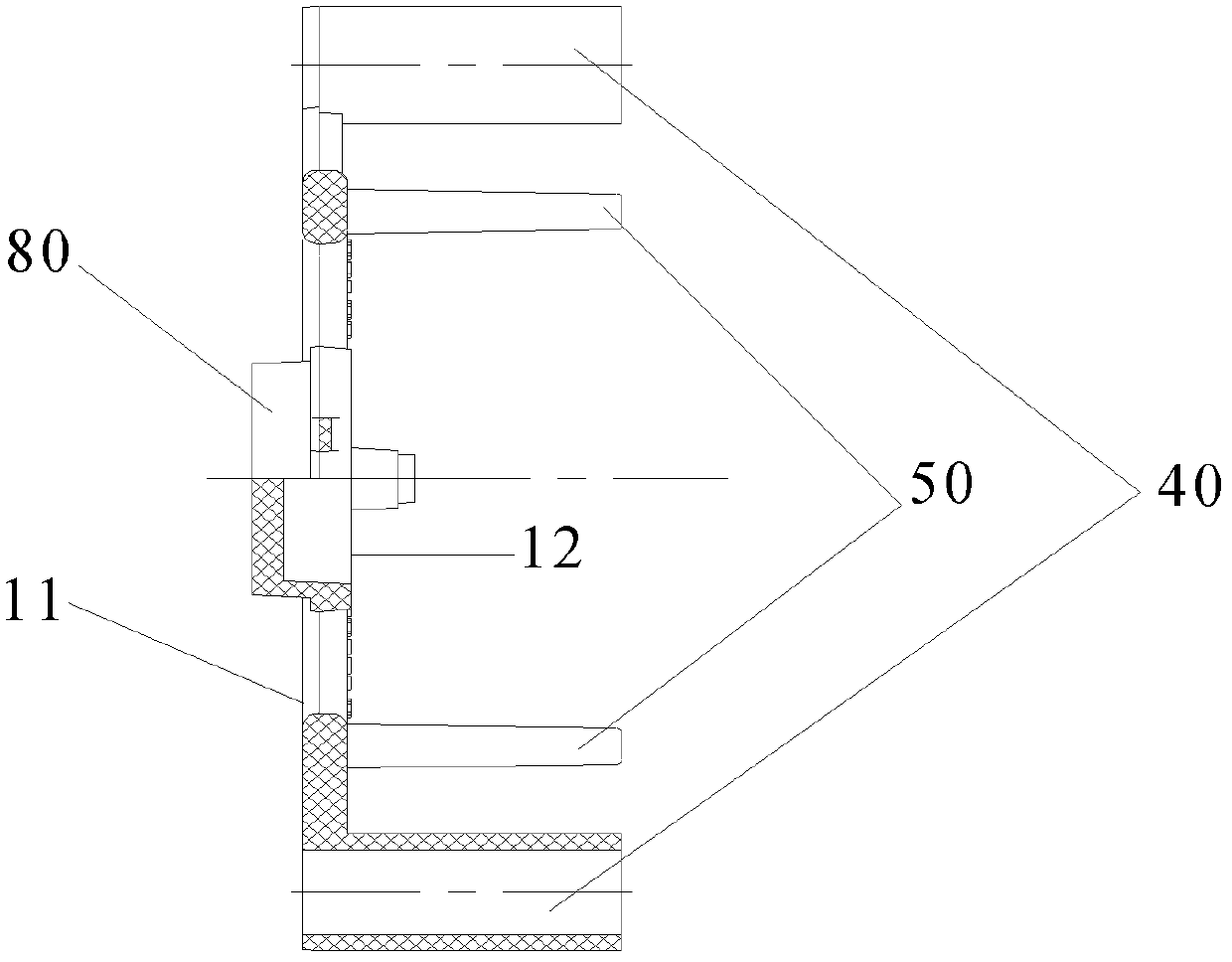

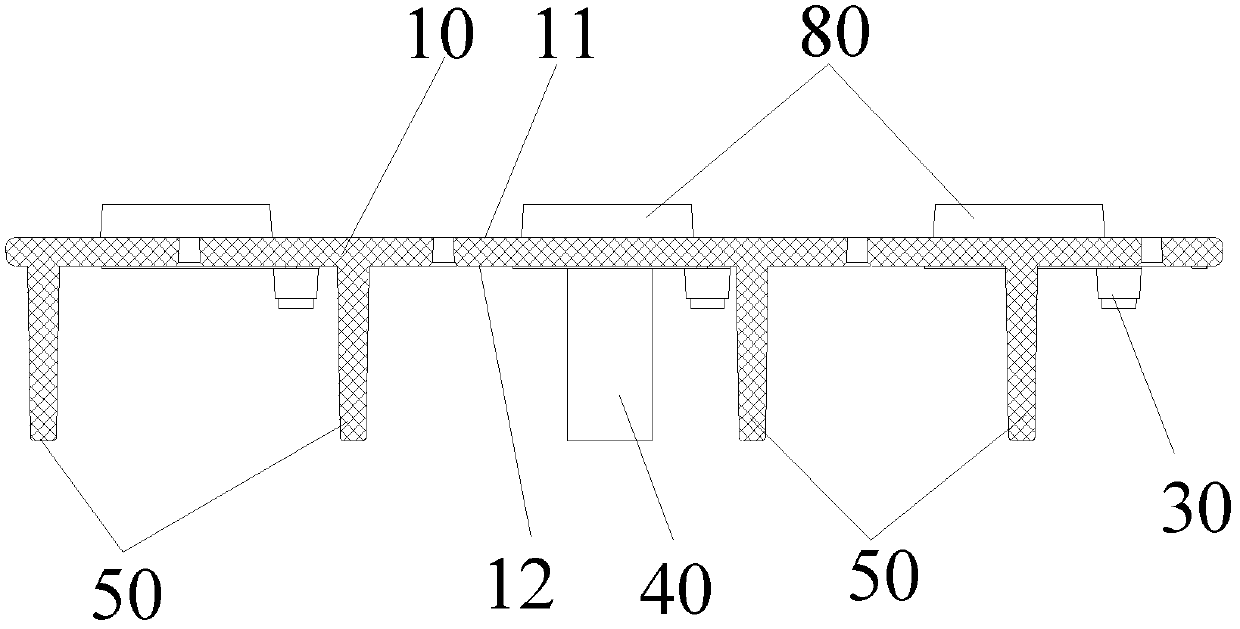

[0025] see figure 1 and Figure 5 , according to the button structure of the present invention, comprising: a rectangular frame body 10, the rectangular frame body 10 has an upper surface 11 and a lower surface 12 and an inner side 13 and an outer side 14 arranged between the upper surface 11 and the lower surface 12, and a button 80 Located in the rectangular frame 10 , one side of the button 80 is connected to the inner side 13 through the elastic band 20 ; By designing the elastic belt of the button 80 into a long strip, compared with the original "L" shaped elastic belt, the design of such a button can greatly reduce the number of mold corrections, and the elastic belt is not easy to stick to the front mold, and the elastic belt is more flexible t

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap