Automatic blocking preventing device for separation plate of garbage compressor

A garbage compactor and anti-clogging technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of environmental heat, cleaning difficulties, etc., and achieve the effect of solving blocked door slots, low cost, and avoiding entry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

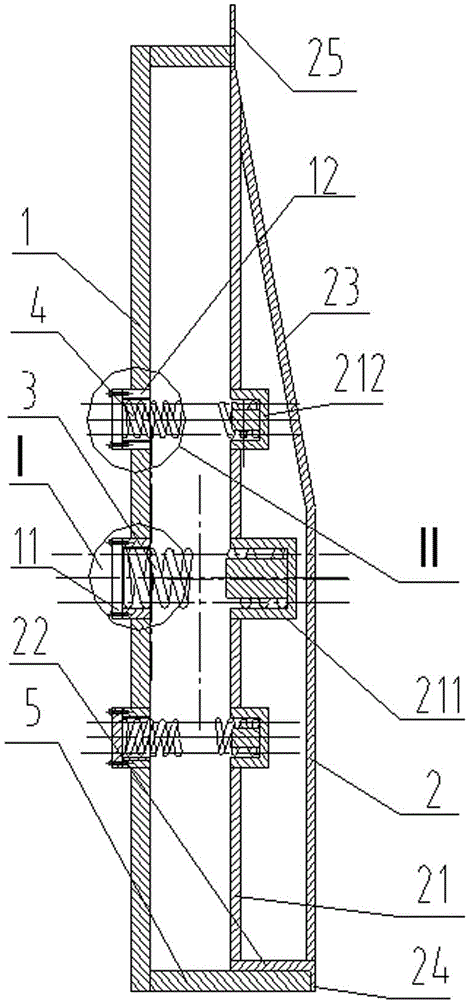

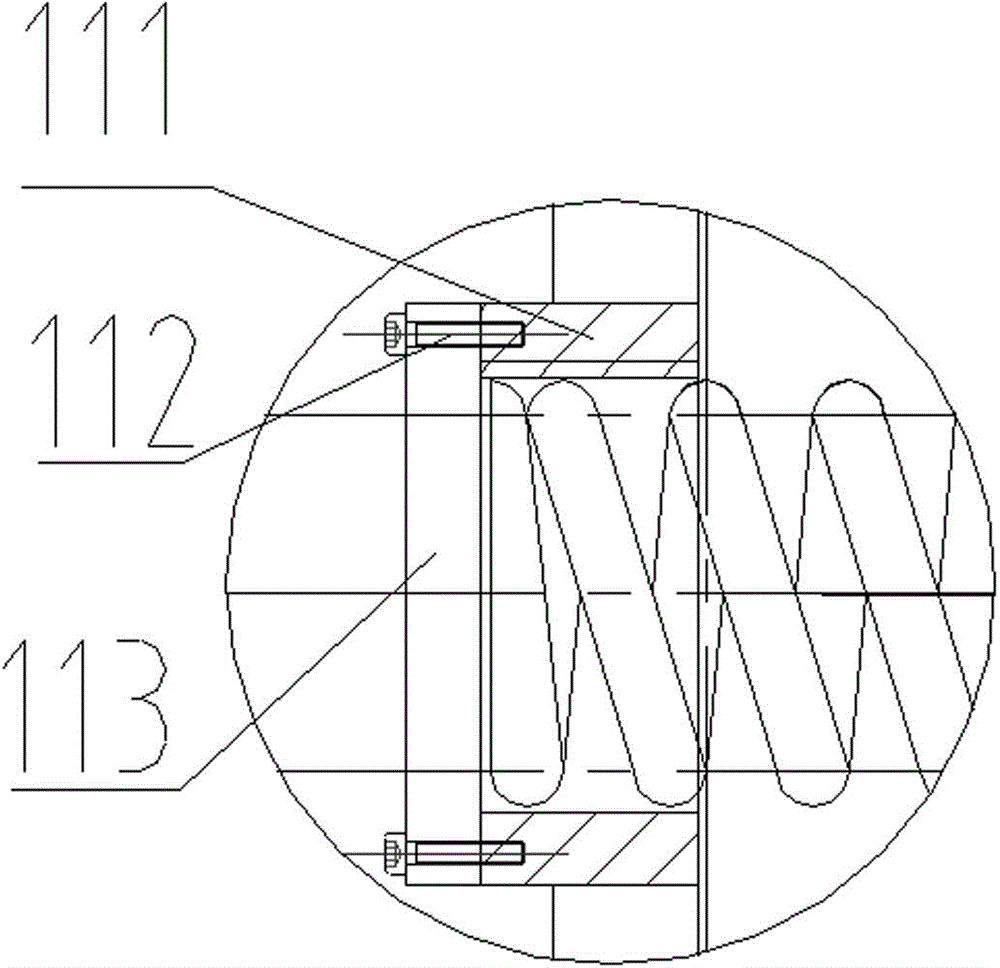

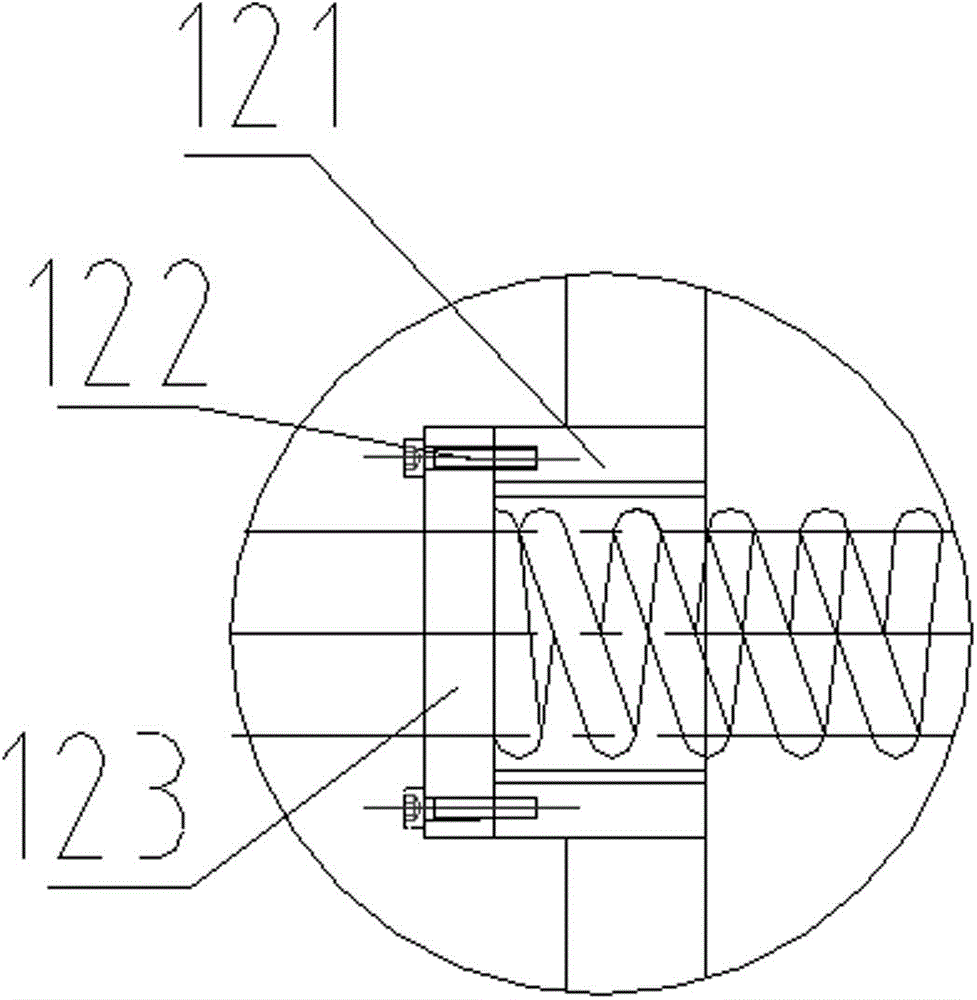

[0019] Such as figure 1 As shown, the present invention includes a compression spring 3, a spacer 2, an auxiliary spring 4, an outer baffle 1 and an outer baffle frame 5; the middle part of the outer baffle 1 is provided with a spring fixing seat 11, and The upper and lower sides of the spring holder 11 are respectively provided with auxiliary spring holders 12, corresponding to the spring holder 11, and the middle part of the occupying block 2 is provided with a spring installation sleeve 211; corresponding to the auxiliary spring holder 12, the upper part of the occupying block 2 An auxiliary spring mounting seat 212 is provided; one end of the compression spring 3 is installed in the spring mounting seat 11, and the other end is installed in the spring mounting sleeve 211; one end of the auxiliary spring 4 is installed in the auxiliary spring mounting seat 12, The

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap