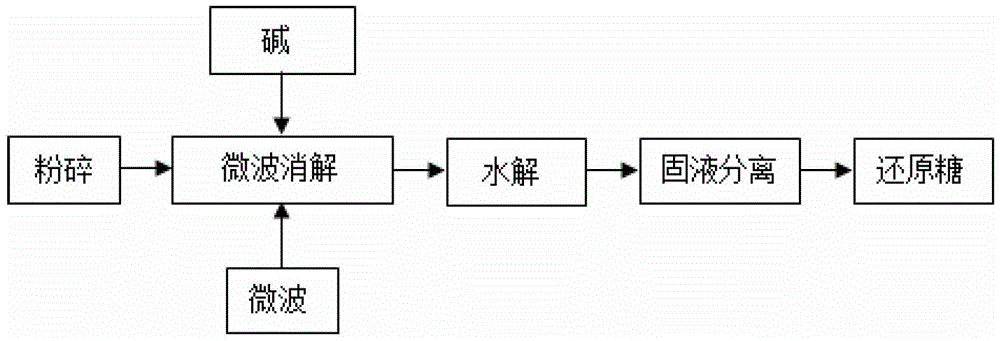

A kind of method that adopts cellulose-containing raw material to prepare reducing sugar

A cellulose and cellulase technology, applied in the direction of fermentation, can solve the problem of low yield of reducing sugar, etc., and achieve the effect of improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This example is used to illustrate the method for preparing reducing sugar from cellulose-containing raw materials provided by the present invention.

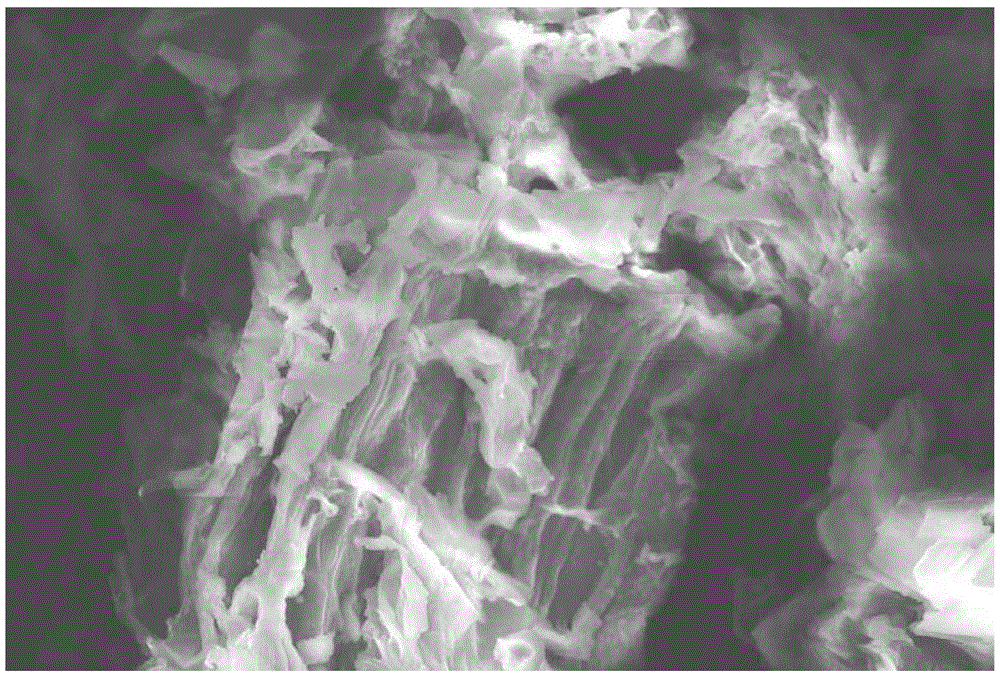

[0039] The rice straw was dried at 100° C. so that the water content therein was 1.5% by weight. And the obtained rice stalks were crushed into powders with a particle size less than 212 microns, then mixed evenly with a sodium hydroxide solution with a concentration of 1.0% by weight in a weight ratio of 2:100, and then in a microwave digestion apparatus (purchased from Shanghai Yiyao Instrument Technology Development Co., Ltd., model WX-8000, the same below), microwave digestion was performed at 100°C for 5 minutes. Wherein, the microwave frequency used in the microwave digestion is 2.45GHz, and the pressure used is 0.1MPa. The microstructure of the cellulose-containing raw material obtained after microwave digestion is as follows: figure 2 shown. from figure 2 It can be seen that the surface and internal structure

Embodiment 2

[0041] This example is used to illustrate the method for preparing reducing sugar from cellulose-containing raw materials provided by the present invention.

[0042] The corn stover was dried at 105° C. so that the water content therein was 1.8% by weight. And the obtained corn stalks were crushed into powder particles with a particle size of less than 270 microns, and then mixed evenly with a potassium hydroxide solution with a concentration of 2% by weight in a weight ratio of 4:100, and then carried out in a microwave digestion apparatus at 150°C. Microwave digestion for 30 minutes. Wherein, the microwave frequency used in the microwave digestion is 2.45GHz, and the pressure used is 0.8MPa. The obtained microwave digestion product was transferred to a hydrolysis vessel, and its pH value was adjusted to 4.8 with hydrochloric acid with a concentration of 5% by weight, and then 3% by weight of cellulase (purchased The hydrolysis was carried out at 40° C. for 96 hours from Japan

Embodiment 3

[0044] This example is used to illustrate the method for preparing reducing sugar from cellulose-containing raw materials provided by the present invention.

[0045] The wheat straw was dried at 95° C. so that the water content therein was 1.6% by weight. And the obtained wheat stalks were crushed into powder particles with a particle size of less than 500 microns, and then mixed evenly with ammonia water with a concentration of 3% by weight in a weight ratio of 3:100, and then microwave digestion was carried out at 135°C in a microwave digestion apparatus for 10 minute. Wherein, the microwave frequency used in the microwave digestion is 2.45GHz, and the pressure used is 0.3MPa. The obtained microwave digestion product was transferred to a hydrolysis vessel, and its pH value was adjusted to 4.2 with hydrochloric acid with a concentration of 8% by weight, and then 5% by weight of cellulase (purchased The hydrolysis was carried out at 38° C. for 84 hours (from Sigma-Aldrich Compa

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap