Manual quick clamp

A fast and specific technology, used in clamping, positioning devices, manufacturing tools, etc., can solve the problems of inability to guarantee the machining accuracy of parts, deformation of parts, poor verticality, etc., to achieve rapid clamping, reduce labor intensity, and reduce deformation. the effect of the possibility of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

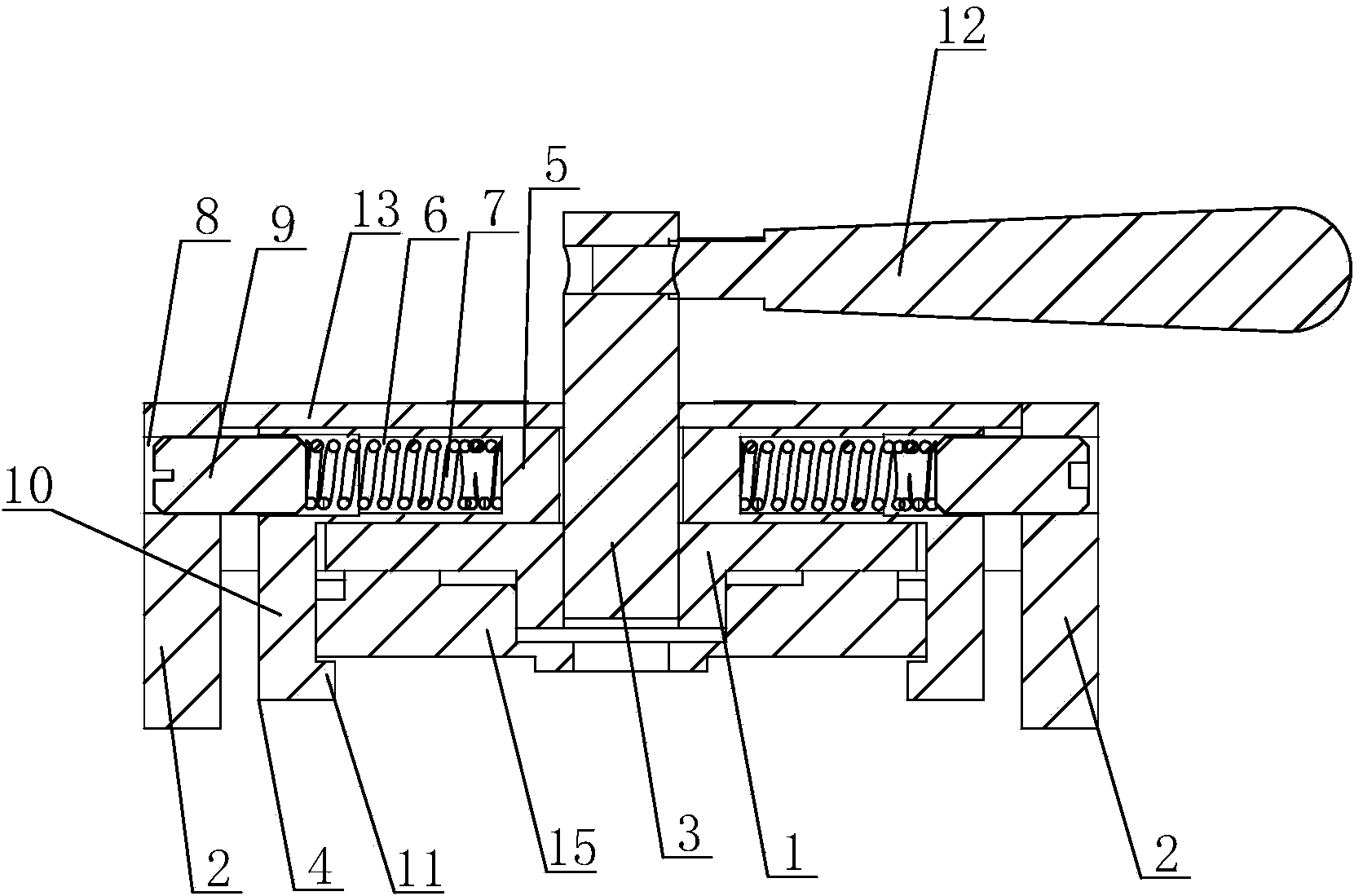

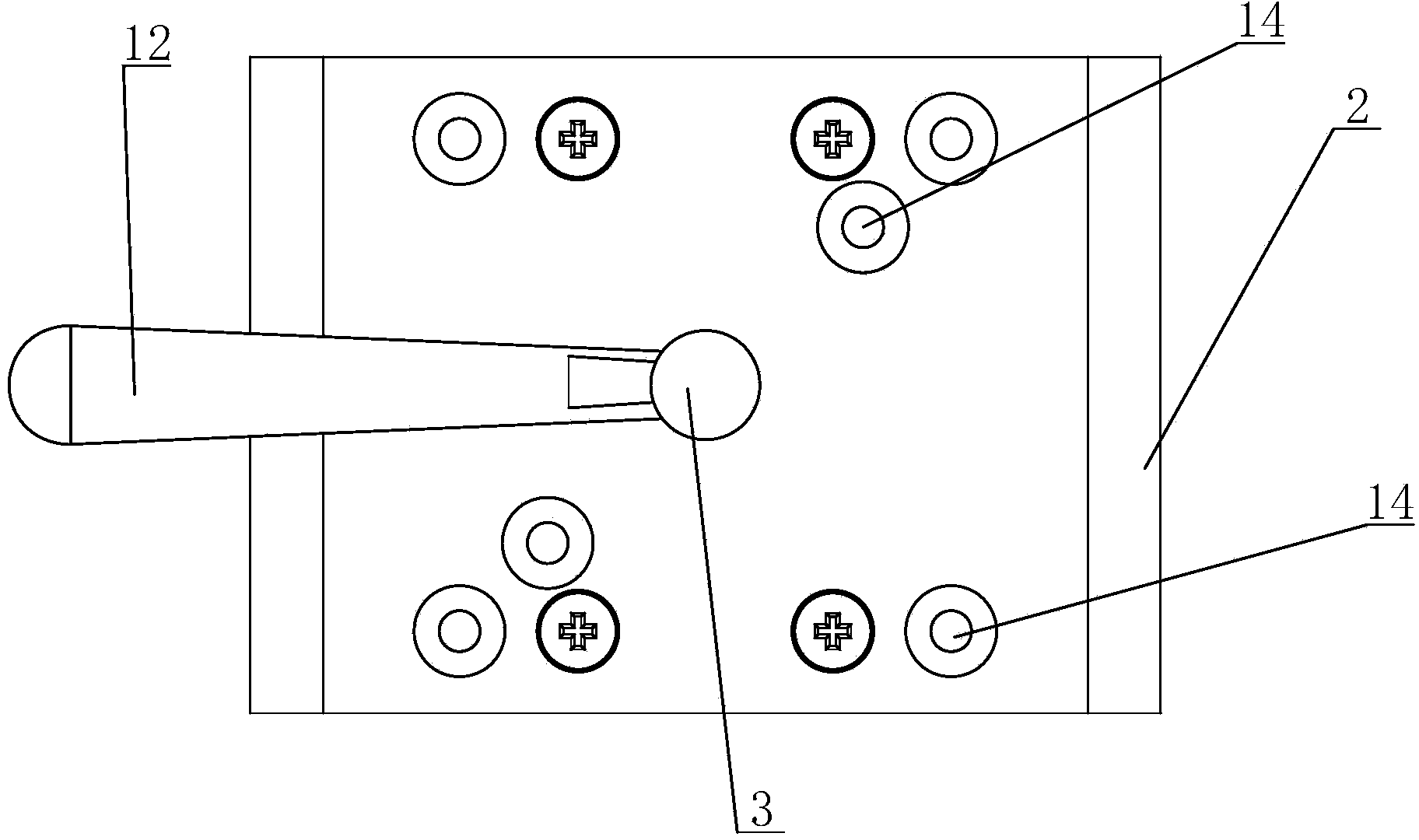

[0015] see figure 1 with figure 2 As shown, in this embodiment, a manual quick clamping fixture includes a clamp body, the clamp body includes a base 1 and side plates 2 arranged at both ends of the base 1, and the center of the base 1 is rotatably The rotating shaft 3 is installed, and the two sides of the base 1 are correspondingly provided with chute, and the positioning clamping plate 4 is arranged in the chute, and the positioning clamping plate 4 includes a connecting part 5 arranged in the chute , the connecting portion 5 is provided with an accommodating groove 6, the accommodating groove 6 is provided with a spring 7, and the corresponding accommodating groove 6 is provided with a threaded hole 8 on the side plate 2, and the threaded hole 8 A set screw 9 for positioning the spring 7 is inst

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap