Coal-saving temperature-controlling fire seal for briquette boilers

A technology for sealing firearms and briquette, which is applied in the field of boilers, can solve the problems of wasting heat energy, burning out and extinguishing the fire, unable to control the sealing fire, etc., and achieves the effect of reducing the use cost, increasing the burning time, and saving coal significantly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

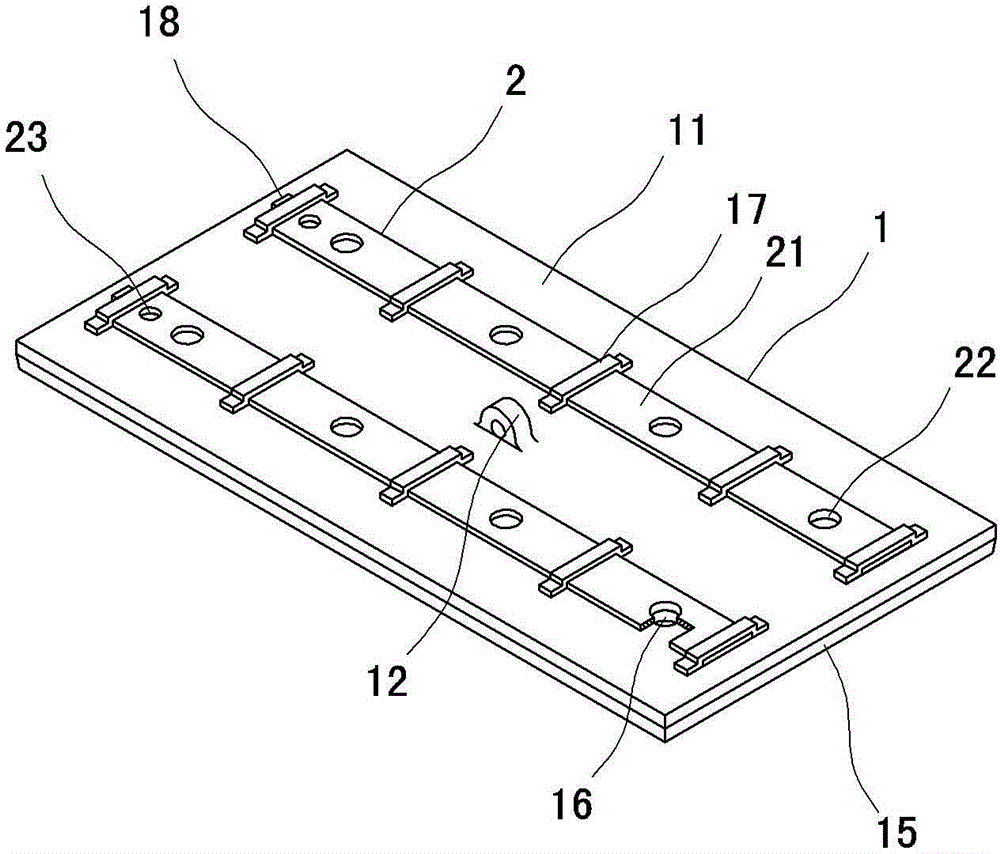

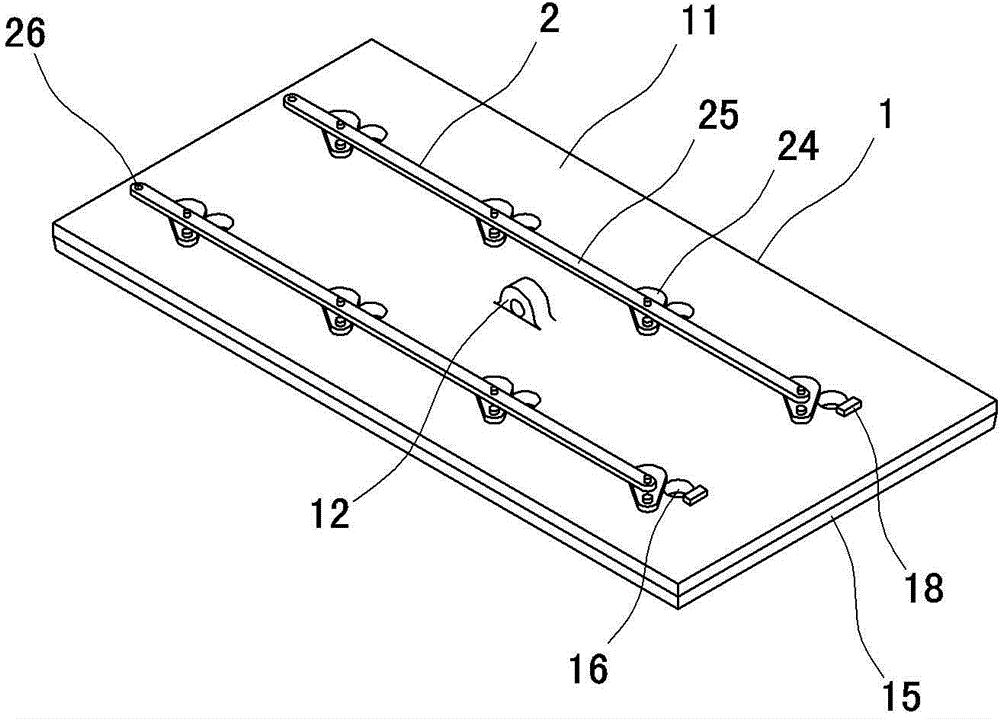

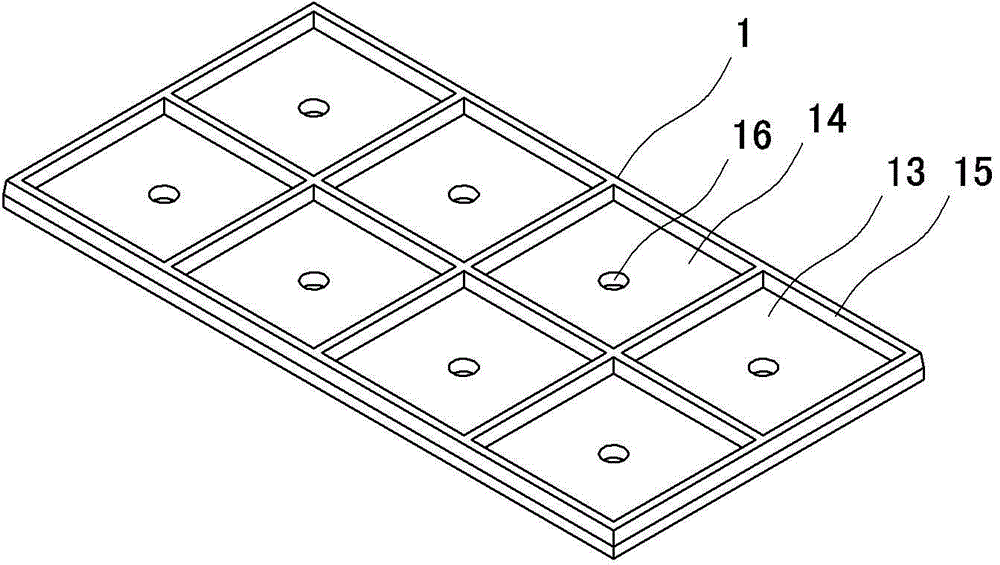

[0016] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, it includes a square plate-shaped body 1 made of high-temperature-resistant cast iron. The center position of the upper plate surface 11 of the body 1 is provided with a pick-and-place lifting ring 12, and the lower plate surface 13 of the body 1 is crossed upward and downward. Reinforcing ribs 15 enclosing a square small combustion chamber 14, the positions of each small combustion chamber 14 on the body 1 are respectively provided with fire sealing adjustment ventilation holes 16 connecting the upper plate surface 11 and the lower plate surface 13 of the body 1, and the upper plate of the body 1 The surface 11 is provided with several air dampers 2 that can adjust the opening of the fire-sealing adjustment ventilation holes 16 that cooperate with each fire-sealing adjustment ventilation hole 16.

[0017] Reinforced vertical ribs 15 cross and are located on the four sides of the lower plate surface 13 of th

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap