Clean burning fireplace with water liner

A clean combustion and water tank technology, applied in the field of combustion furnaces, can solve the problems of incomplete combustion of combustible gas, uneven air distribution in the main combustion area, and non-compliance with energy-saving and emission-reduction policies. It achieves simple structure, easy popularization and application, Creatively conceived effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

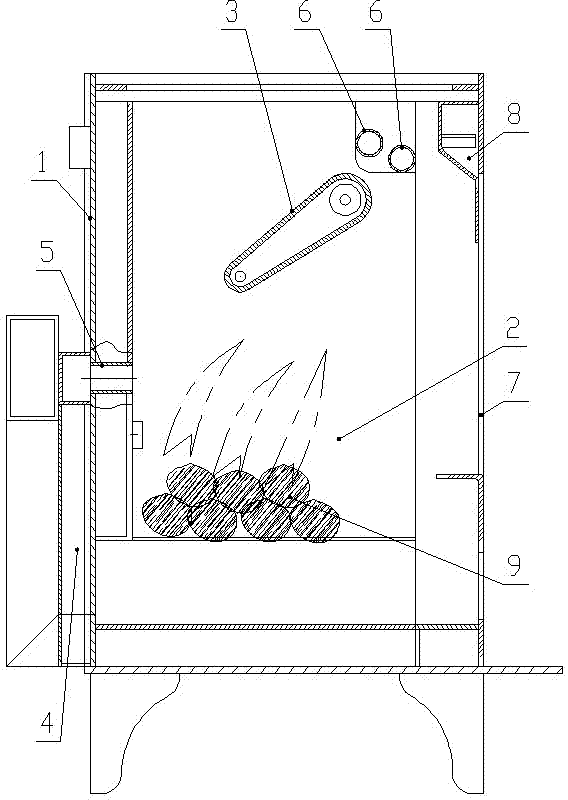

[0010] like figure 1 As shown, a clean burning water tank fireplace of the present invention comprises a furnace body 1, an inner water bladder 3 is provided on the upper part of the furnace 2 of the furnace body 1, and a rear air inlet channel 4 is provided on the rear side of the furnace body 1, and the rear air inlet channel 4 communicates with the middle part of the furnace 2 through the rear inlet air pipe 5 . The upper front side of the furnace body 1 is provided with a secondary air inlet pipe 6 for blowing air into the furnace 2 . The front side of the furnace body 1 is provided with a transparent glass 7 and a glass washing air duct 8 for cleaning the transparent glass 7 .

[0011] When working, the fuel 9 is sent to the bottom of the furnace 2 for combustion, and there are more unburned CO combustible gases in the flue gas generated by the combustion, which is sent to the middle of the furnace 2 through the rear air duct 4 and the rear air duct 5 The air is sent into

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap