Full-automatic rubberized fabric film-sleeving packaging machine

A packaging machine, fully automatic technology, applied in packaging, wrapping paper, transportation packaging, etc., can solve the problems of low accuracy, low production efficiency, high cost, and achieve the effect of improving adaptability, convenient operation and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0031] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings.

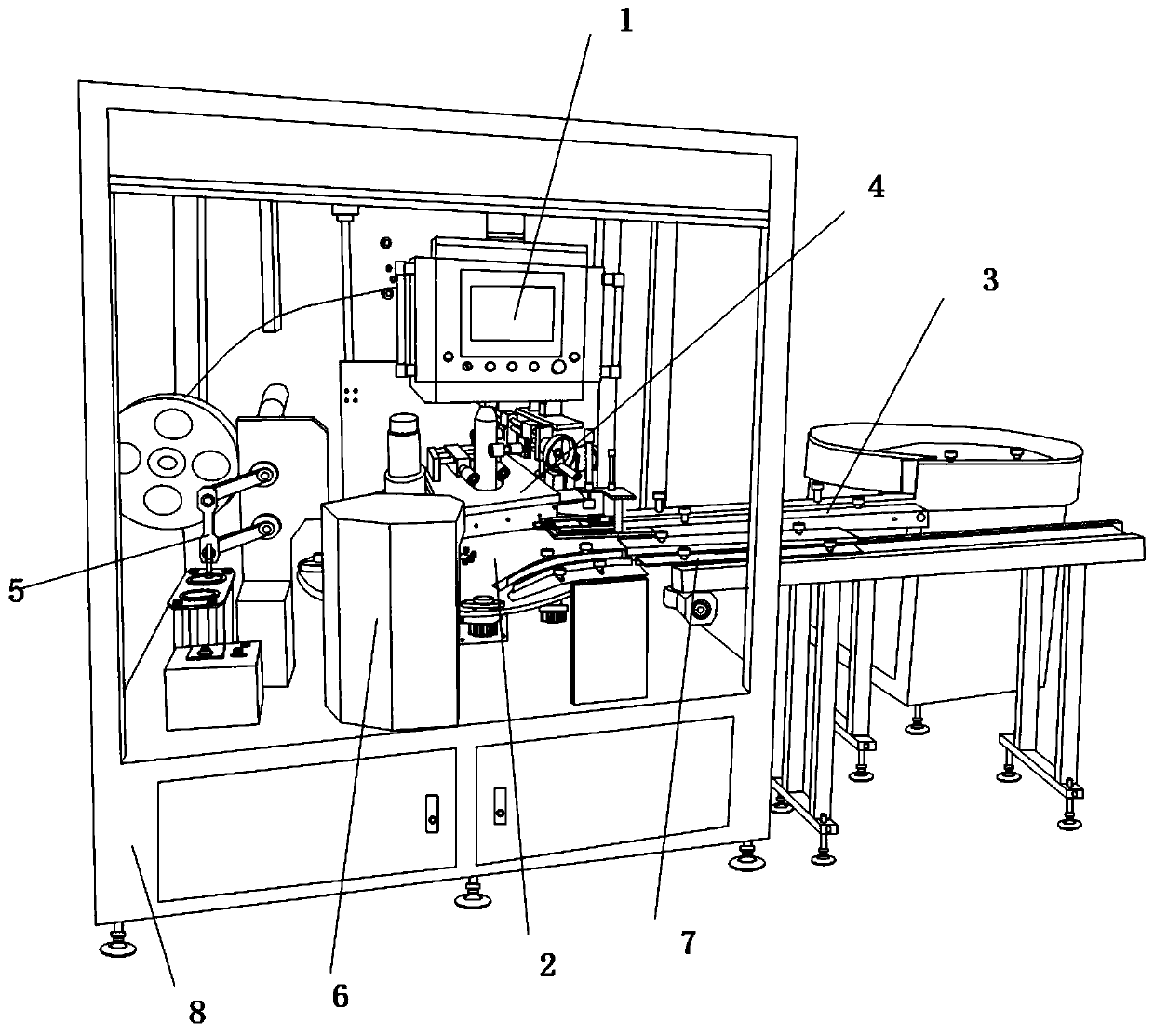

[0032] Reference figure 1 Schematic diagram shown.

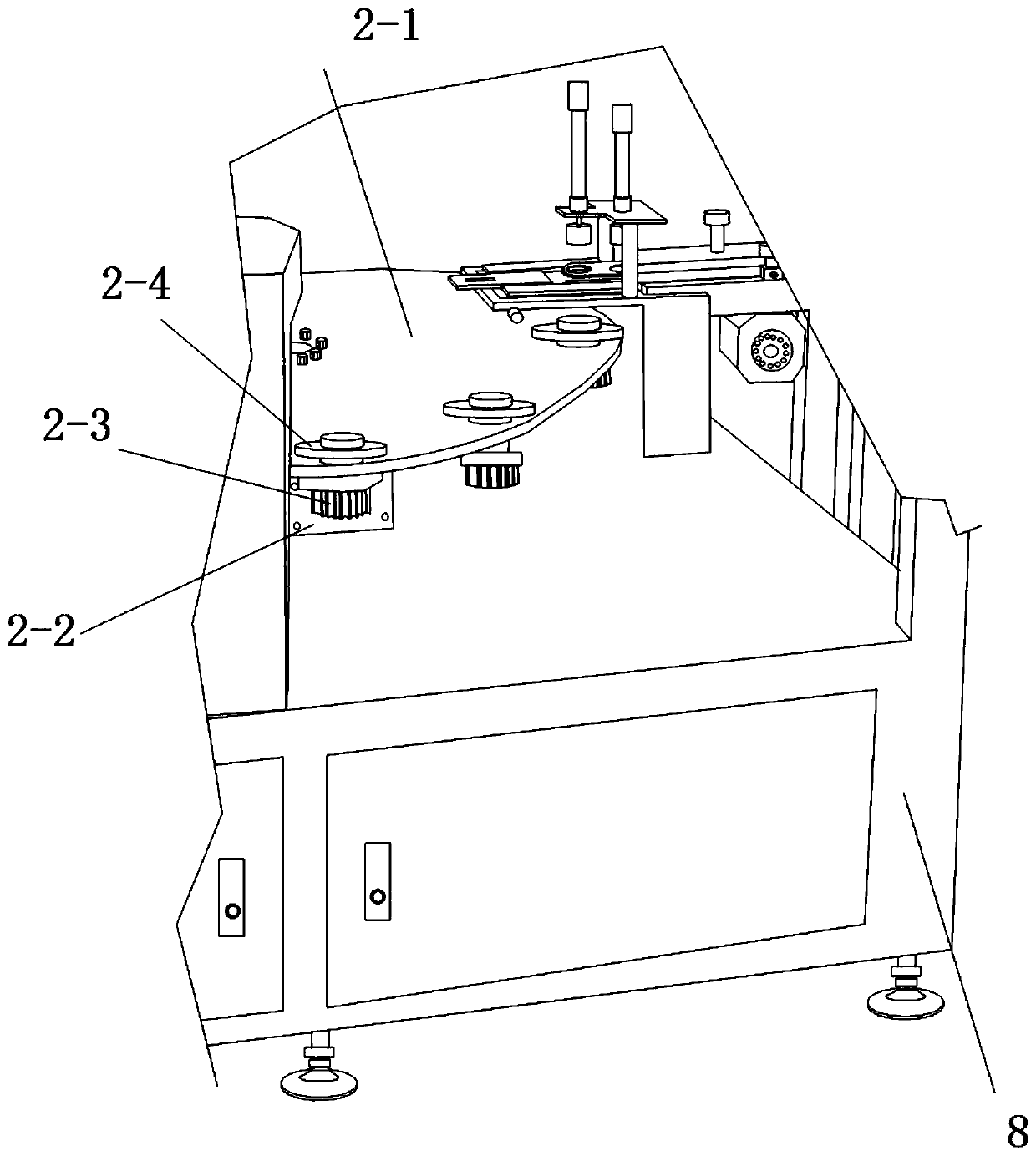

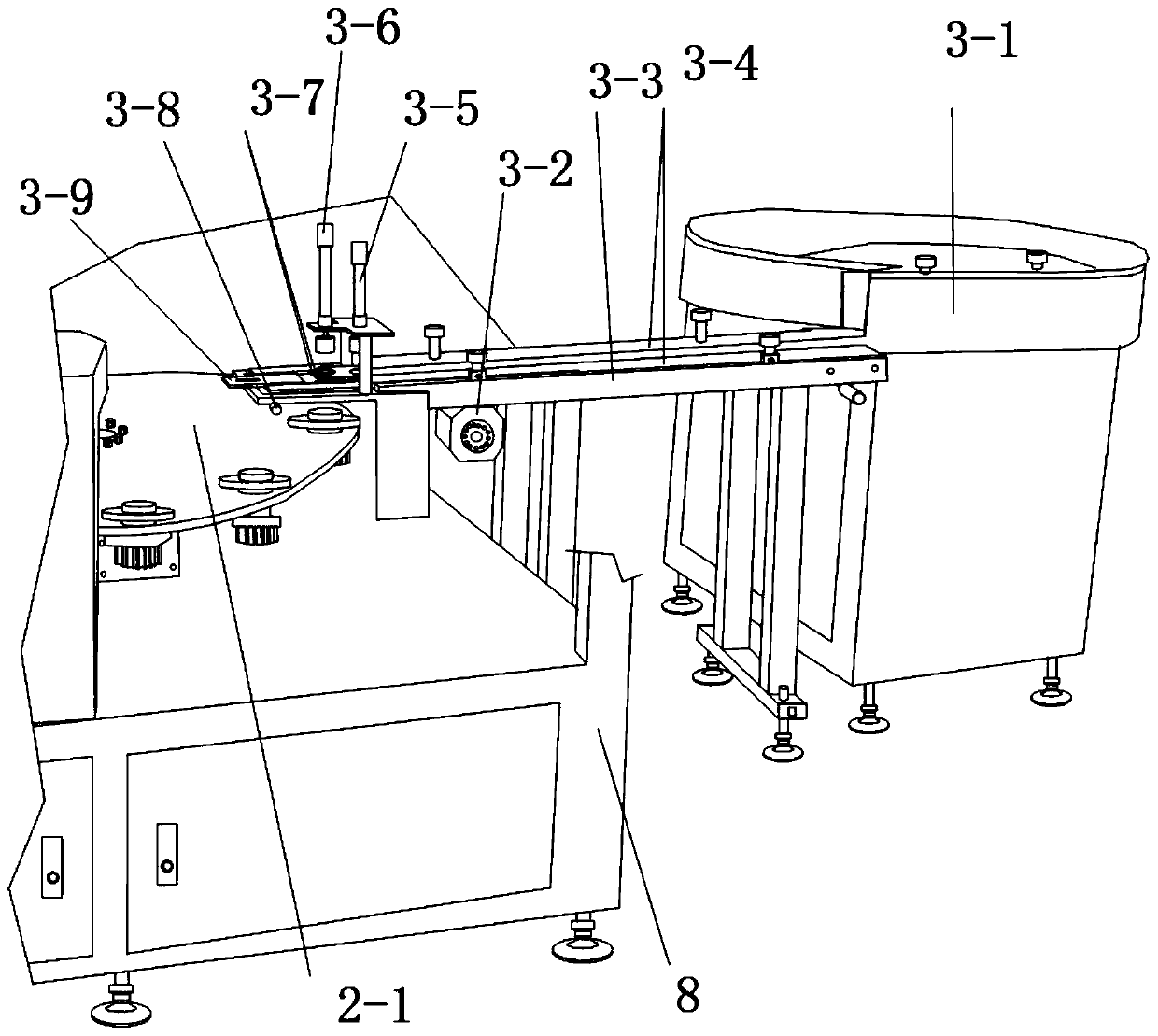

[0033] An embodiment of the present invention is a fully automatic tape cover film packaging machine, including a frame 8 constituting the whole machine, a control center display screen 1, a turntable mechanism 2, a feeding mechanism 3, a film feeding and cutting film cover mechanism 4, and a suction label feeding mechanism. Marking mechanism 5, rotating heating and blowing shrinking film mechanism 6, discharging mechanism and other parts 7.

[0034] The reasonable positioning and fixing of each part of the whole machine, the reasonable distribution of each control circuit and the reasonable positioning instructions of each operation button make the machine integrated and beautiful in appearance.

[0035] The control ce

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap