Clamping encapsulation structure for arc barriers

A technology of encapsulation structure and arc barrier, which is applied in the direction of circuit breaker components, etc., can solve the problems of weak arc extinguishing ability and complicated manufacturing process, and achieve the effect of enhancing arc extinguishing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

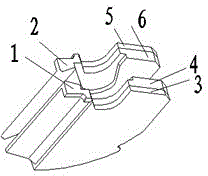

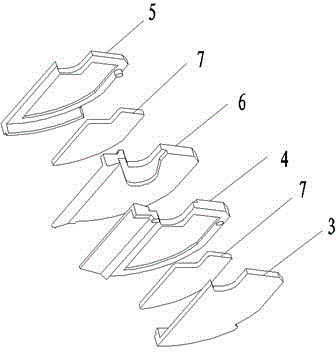

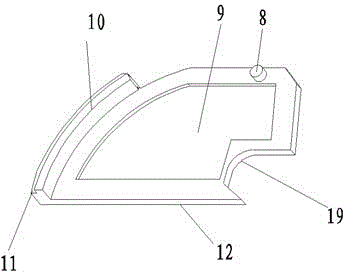

[0021] Please refer to figure 1 — Figure 5 As shown, the arc baffle clamping packaging structure of the present invention includes an upper arc baffle 1 and a lower arc baffle 2, and the upper arc baffle and the lower arc baffle are respectively provided with inner spacers 4, 6 and outer spacers 3, 5 and the magnetic-conducting part 7, the material of the inner spacer is a gas-producing material, and a groove 18 is provided to cooperate with the static contact, and a groove 15 for fastening with the magnetic-conductive part is reserved, the inner spacer, the outer The spacer embeds the magnetic guide parts in the preset grooves and fastens and clamps each other. When the arc is generated, the arc contacts the gas-generating materials of the left and right inner spacers, making it vaporize and generating gas containing hydrogen. This gas can cool the arc

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap