Layout structure of current limiting switch

A technology of layout structure and current limiting switch, which is applied to the parts of the protection switch, the operation/release mechanism of the protection switch, the protection switch, etc. The effect of optimizing the structure layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

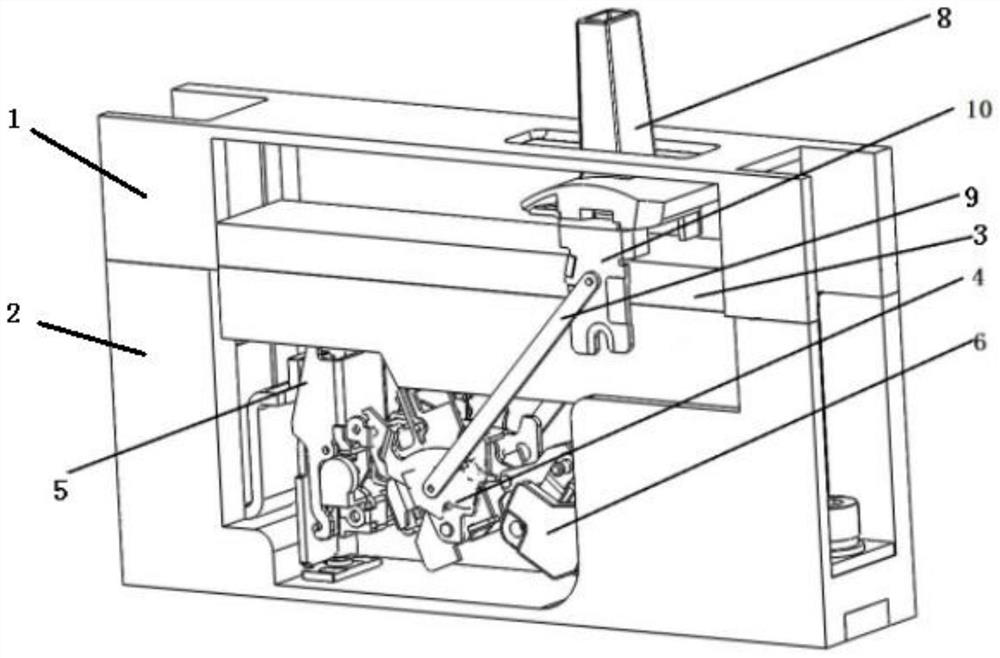

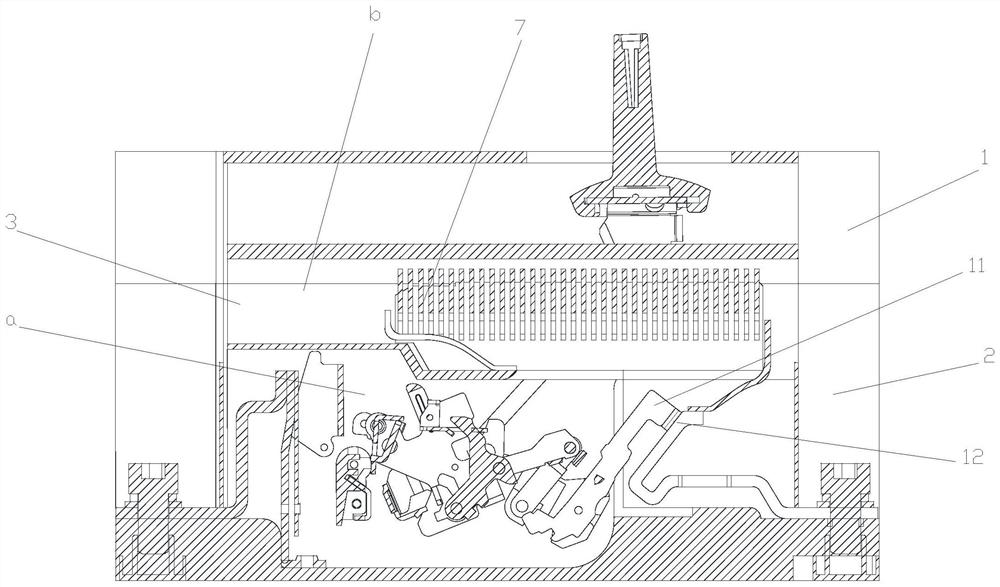

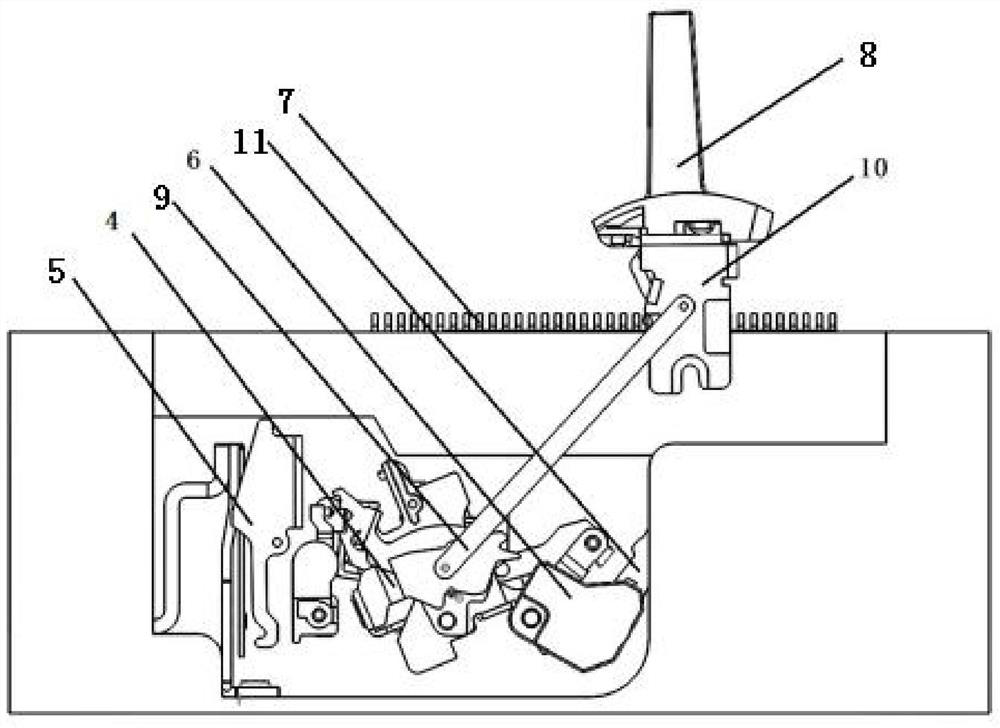

[0023] as attached figure 1 and 2 As shown, the layout structure of a current limiting switch provided by the present invention includes a middle cover 1 and a base 2, the middle cover 1 and the base 2 are assembled together in the up and down direction, and the base 2 is equipped with There is a chamber a, and the arc extinguishing system unit box 3 is located on the upper part of the chamber a, as attached image 3 As shown, in this embodiment, the arc extinguishing system unit box 3 is overlapped and fixedly installed on the upper part of the chamber a and can be disassembled independently, and the arc extinguishing system can occupy the entire base without increasing the overall appearance size of the product. The upper space of the cavity maximizes the capacity of the arc extinguishing chamber, and at the same time, it can elongate the arc and evenly enter the arc extinguishing chamber, so as to speed up the transfer speed of the arc.

[0024] as attached figure 1 And att

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap