Pulling force test clamp

A technology of tensile testing and fixtures, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of affecting work efficiency, difficult to guarantee the quality of wire harnesses, and can not be clamped, so as to improve accuracy, improve production efficiency, reduce The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to facilitate those skilled in the art to understand the technical content of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

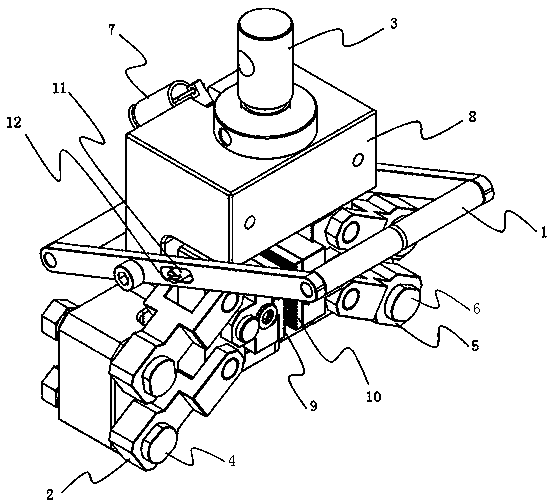

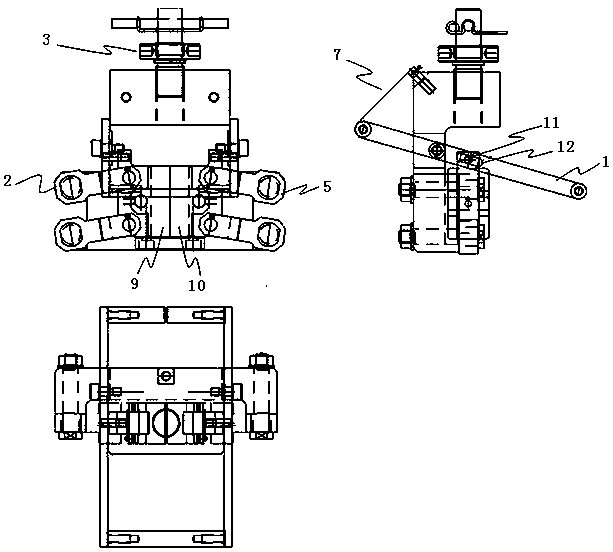

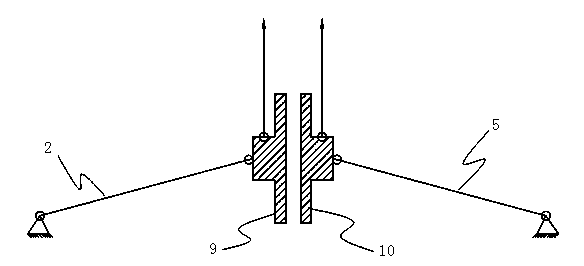

[0020] Such as figure 1 Shown is a wire harness pull test fixture, including a fixture body, a tie rod, a left moment arm, a right moment arm, a left clamp, and a right clamp. The pull rods are arranged at both ends of the clamp body through bolts, and the left moment arm and the right moment arm are arranged at the front side door of the fixture body through bolts, and the left moment arm and the right moment arm can respectively rotate in a fan-shaped area around the bolt axis. The left splint is connected to the left arm by bolts and the protrusion on the left splint is limited in the groove on the pull rod, the right splint is connected to the right arm by bolts and the protrusion on the right splint is limited to the groove on the ri

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap