Crystal carrying table body transmission device and assembling and operating method thereof

A transmission device and crystal-carrying technology, which is applied in the direction of machines/supports, supporting machines, mechanical equipment, etc., can solve the problem of inaccurate imaging and achieve high transmission efficiency, stable transmission, and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further elaborated below in conjunction with the accompanying drawings of the description.

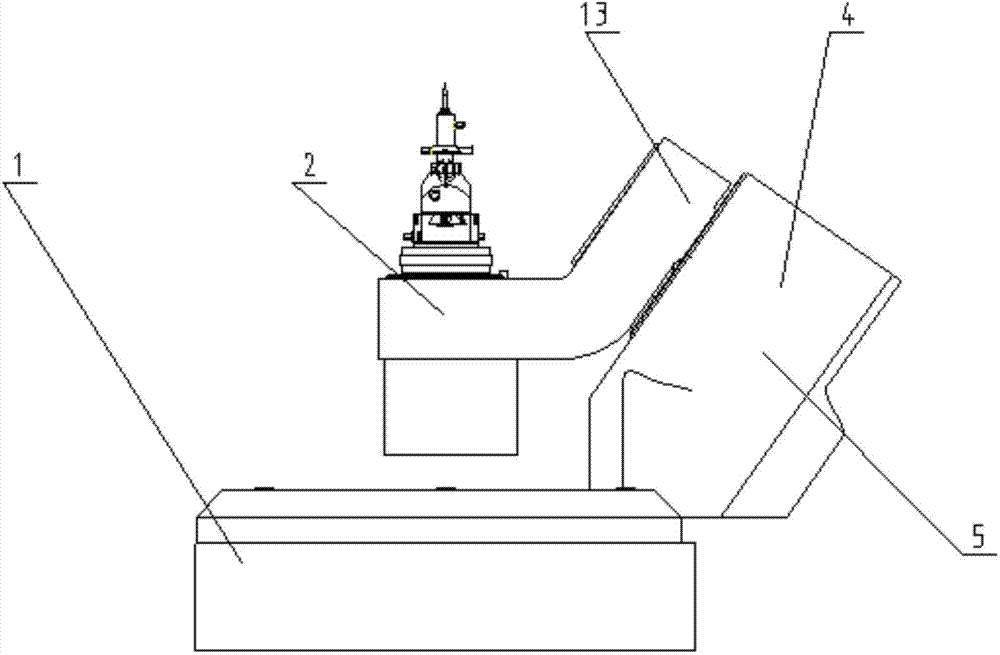

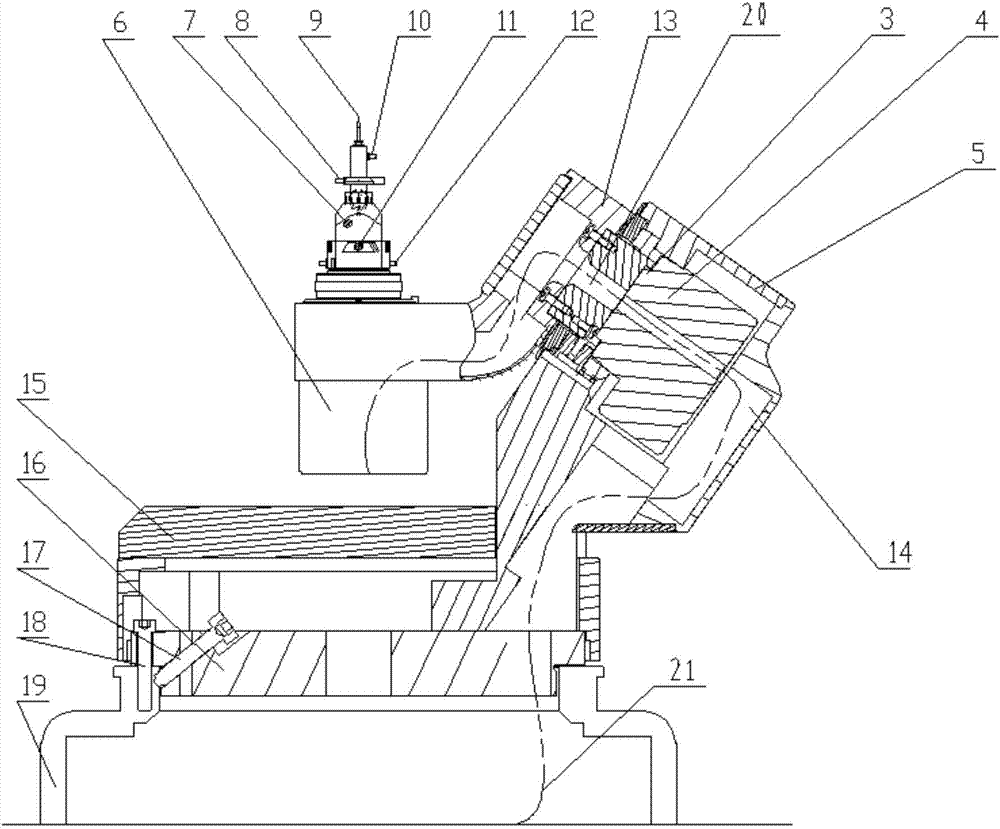

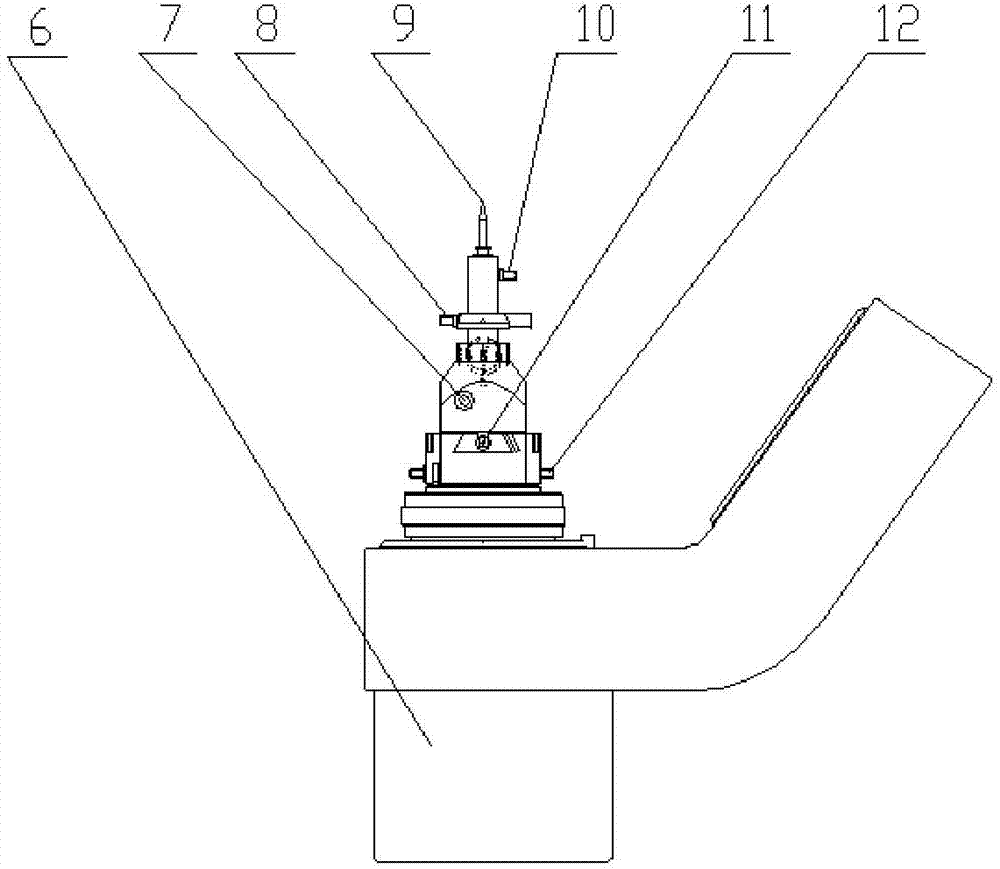

[0039] Such as figure 1 , 2 As shown, the crystal loading platform transmission device of the present invention has a rotary table 1, a crystal loading platform 2, a harmonic drive reduction device 3, a motor 4, a motor connecting frame 5 and a chassis 19, wherein the rotary platform 1 is connected to the chassis 19 , one side of the turntable 1 is equipped with a motor connecting frame 5, and a motor 4 is installed in the motor connecting frame 5, and the output shaft of the motor 4 is connected to the crystal table holder 13 through a harmonic drive reduction device, and the crystal table holder 13 is A crystal loading platform 2 and a crystal position adjustment mechanism are provided; the harmonic transmission deceleration device 3, the motor 4 and the motor connecting frame 5 are integrally inclined to the outside of the rotary table 1; the outpu

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap