Self-coupling step-down compensation integrated soft start device

A soft start and self-coupling technology, applied to the starter of a single single-phase induction motor, motor generator/starter, etc., can solve the problems of excessive starting current and small size, and achieve fast response, small size, Smooth start-up performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to facilitate those of ordinary skill in the art to understand and implement the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the implementation examples described here are only used to illustrate and explain the present invention, and are not intended to limit this invention.

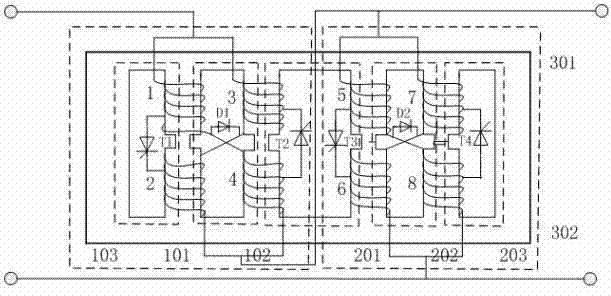

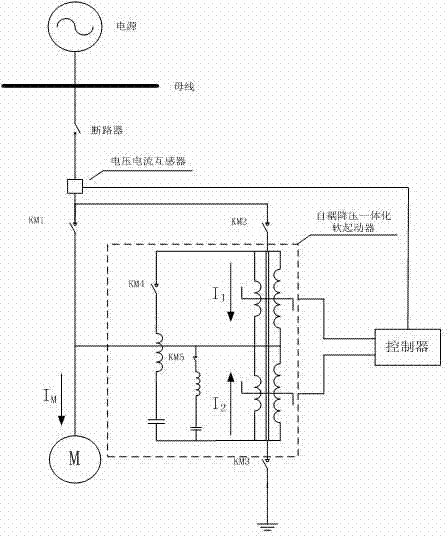

[0025] The invention includes a magnetic valve type controllable reactor, a thyristor excitation system, a controller and an additional parallel compensation capacitor bank. The invention couples the two functions of an autotransformer and a magnetic valve type controllable reactor together through circuit and magnetic circuit design, including a high-voltage side magnetic core, a low-voltage side magnetic core and a winding.

[0026] please see figure 1 , the technical solution adopted in the present invention is: an auto-coupling step-down compensation integr

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap