Centrifugal compressor

A centrifugal compressor and rotor technology, which is used in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of high rotational speed of centrifugal compressors, increased compressor shape and structure, and high gear noise, and achieves low noise and improved performance. The effect of energy conversion efficiency and simple shape and structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

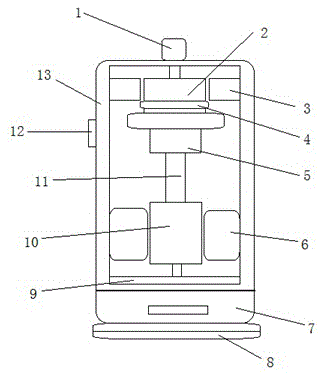

[0009] refer to figure 1 As shown, the present invention adopts the following technical scheme: a centrifugal compressor, including an air inlet 1, a movable scroll 2, a fixed scroll 3, an anti-rotation slip ring 4, a main bearing 5, a stator 6, a lower shell 7, a base 8. Separator 9, rotor 10, crankshaft 11, air outlet 12 and housing 13, the air inlet 1 is arranged on the top of the housing 13, the housing 13 is fixed on the lower shell 7, the lower shell 7 is set on the base 8, the space between the rotor 10 and the stator 6 is a sealed space, the air outlet 12 is set on the side of the housing 13, and the anti-rotation slip ring 4 is set between the movable scroll 2 and the main bearing 5 between.

[0010] The rotor 10 is connected to the main bearing 5 through the crankshaft 11, the partition plate 9 is arranged between the rotor 10 and the lower casing 7, the casing 13 and the lower casing 7 form a sealed space, and the space between the rotor 10 and the stator 6 is Th

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap