Sanitation garbage truck trunk

A technology for garbage trucks and garbage, which is applied to garbage bins, garbage collection, and garbage receptacles, etc. It can solve problems such as cumbersome operation process, strong garbage odor, and prolonged garbage collection process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

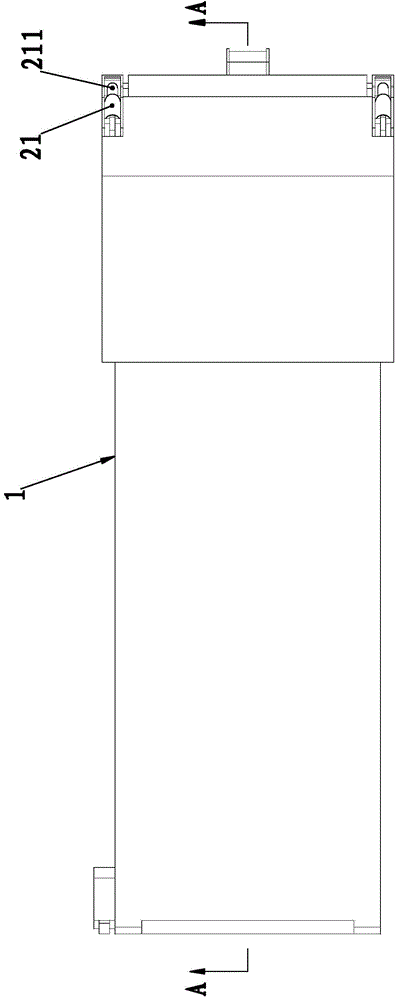

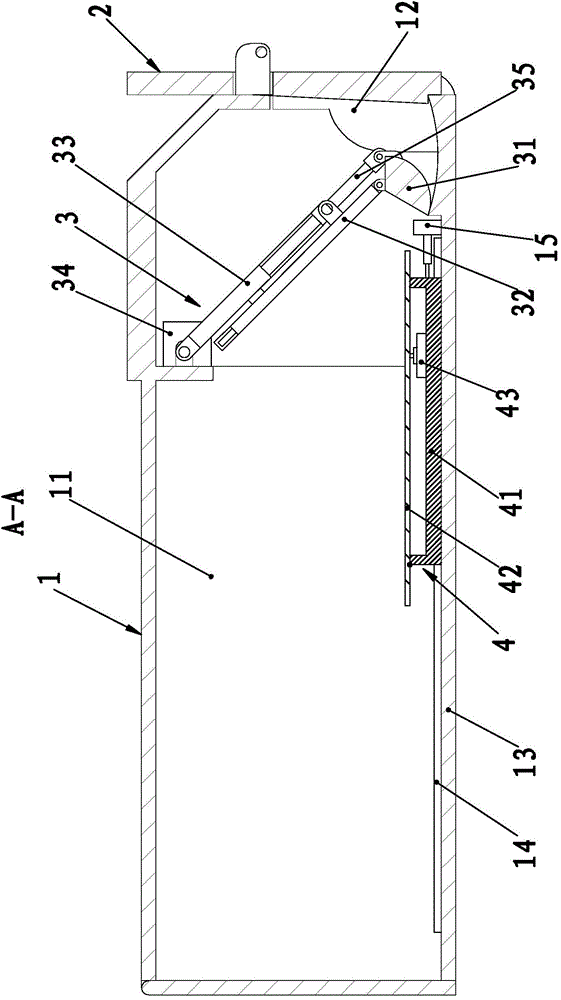

[0018] Such as figure 1 — figure 2 The illustrated sanitation garbage truck box includes a box body 1 with an inner cavity 11, one end of the box body 1 is provided with a garbage injection port 12, and the garbage injection port 12 is provided with a flip cover that can close or prompt the garbage injection port 12 to open 2. There is a garbage receiving mechanism 3 and a garbage conveying mechanism 4 connected to the garbage receiving mechanism 3 at the garbage injection port 12. The garbage receiving mechanism 3 includes one end hinged to the top of the box body 1, and the other end extends to the bottom plate 13 of the box body 1. The accommodating claw 31 can swing along the hinge, and the garbage conveying mechanism 4 includes a mounting frame 41 that cooperates with the bottom plate 13 of the box body 1 to form a guide groove and an inverting conveying plate 42 that can be turned over along the mounting frame 41. In the above solution, by setting one end of the garbage inj

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap