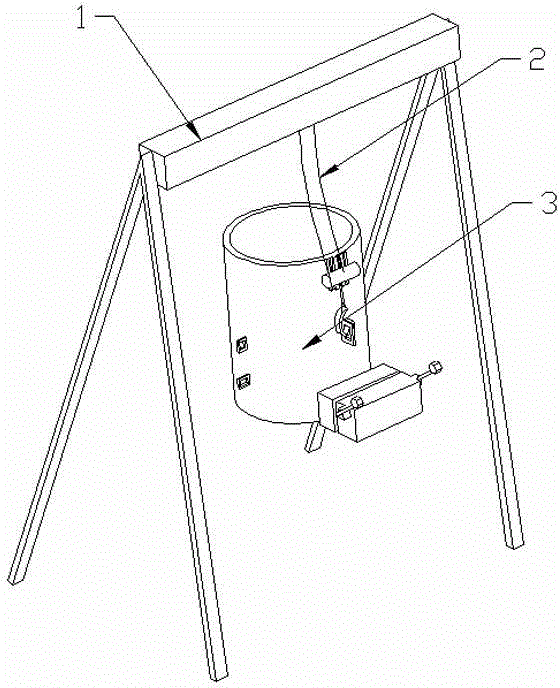

Method for hoisting ultrahigh spud leg by stock gantry crane

A dock gantry crane hoisting and pile leg technology, which is applied in the field of dock gantry crane hoisting super high pile legs, can solve the problems of low efficiency and achieve the effect of shortening time and widening market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0016] Take a 100,000-ton oil tanker as an example:

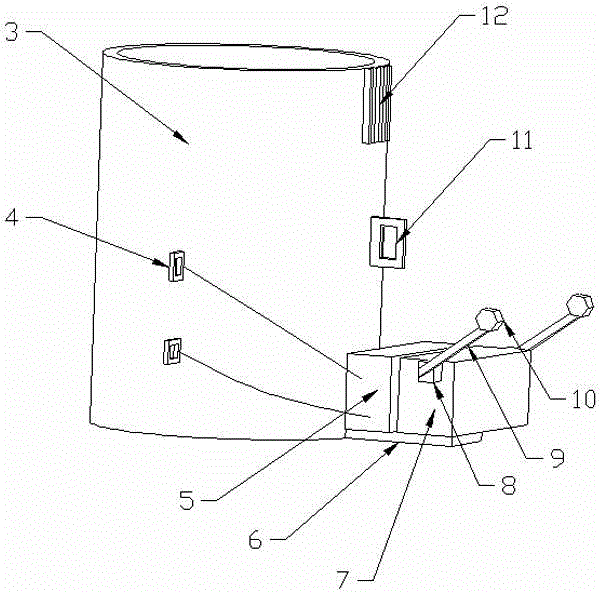

[0017] A method for hoisting super-high pile legs with a dock gantry crane, comprising a gantry crane 1, a hook 2, a pile leg 3, a hook 4, a sandbox 5, a supporting plate 6, a water tank 7, a reduction motor 8, a rotating arm 9, a counterweight 10, Lifting lug 11 and slide plate 12, first install a supporting plate 6 at the bottom of pile leg 3, sandbox 5 and water tank 7 are installed on supporting plate 6, reducer motor 8 is installed on both sides of water tank 7, and rotating arm is installed on the rotating shaft of reducer motor 8 9. A counterweight 10 is installed on the rotating arm 9 .

[0018] The gantry crane 1 is slowly opened, the hook 2 is hung on the lifting lug 11, and the lifting lug 11 is welded to the middle of the pile leg 3, so that it can be pulled higher; And hook 4 and sandbox

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap