Organic carbon suspension liquid compound fertilizer and preparation method thereof

A compound fertilizer and suspended liquid technology, applied in the directions of organic fertilizers, liquid fertilizers, inorganic fertilizers, etc., can solve the problems such as the inability to realize the integration of water and fertilizer, and achieve the effects of improving stress resistance, improving utilization rate and increasing fertilizer efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] The organic carbon suspension liquid compound fertilizer described in the present embodiment contains each component of following parts by weight:

[0056]

[0057] The specific preparation method of the organic carbon suspension liquid compound fertilizer comprises the following steps:

[0058] S1. Dissolve the molasses, sodium octaborate tetrahydrate, EDTA-Zn and EDTA-Mn of the above compound fertilizer formula in 2 / 3 of the water, and stir for 15 minutes to obtain the mother liquor;

[0059] S2. Add humic acid powder to the mother liquor, stir while adding, and stir for 30 minutes to form black thick liquid;

[0060] S3. At 75°C, slowly add monoammonium phosphate, ammonium nitrate, urea, potassium nitrate, and potassium chloride to S2, stir while adding, keep the reaction temperature at 75°C, and stir for 40 minutes to form a viscous fluid;

[0061] S4. When the temperature of S3 drops to normal temperature, add sodium alginate oligosaccharides and betaine to the

Embodiment 2

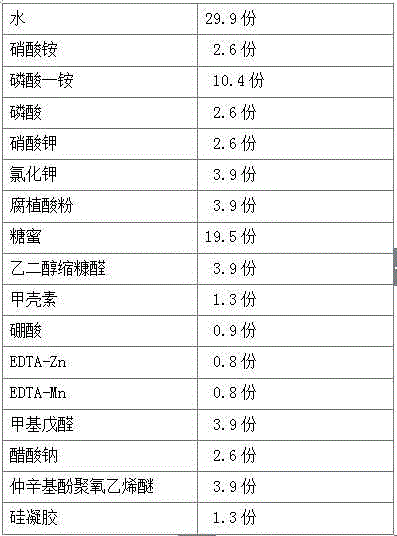

[0066] The organic carbon suspension liquid compound fertilizer described in the present embodiment contains each component of following parts by weight:

[0067]

[0068] The specific preparation method of the organic carbon suspension liquid compound fertilizer comprises the following steps:

[0069] S1. Dissolve the leftovers from the monosodium glutamate factory, sodium octaborate tetrahydrate, boric acid, EDTA-Zn and EDTA-Mn in 2 / 3 of the above compound fertilizer formula, and stir for 15 minutes to obtain the mother liquor;

[0070] S2. Add humic acid powder to the mother liquor, stir while adding, and stir for 30 minutes to form black thick liquid;

[0071] S3. Slowly add urea phosphate to S2, stir while adding at 80°C, and stir for 25 minutes to form a viscous fluid; after the urea phosphate is completely dissolved, slowly add monoammonium phosphate, ammonium polyphosphate, urea, and potassium chloride respectively , stirring while adding, keeping the reaction t

Embodiment 3

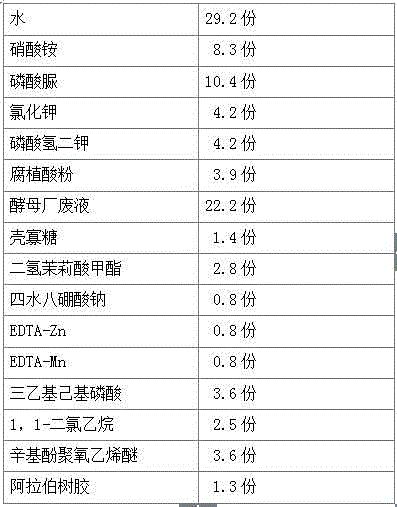

[0077] The organic carbon suspension liquid compound fertilizer described in the present embodiment contains each component of following parts by weight:

[0078]

[0079] The specific preparation method of the organic carbon suspension liquid compound fertilizer comprises the following steps:

[0080] S1. Dissolve the yeast factory waste liquid, boric acid, EDTA-Zn and EDTA-Mn of the above compound fertilizer formula in 2 / 3 of the water, stir for 15 minutes, and obtain the mother liquor;

[0081] S2. Add humic acid powder to the mother liquor, stir while adding, and stir for 30 minutes to form black thick liquid;

[0082] S3. Slowly add urea phosphate to S2, stir while adding at 80°C, and stir for 25 minutes to form a viscous fluid; after the urea phosphate is fully dissolved, slowly add monoammonium phosphate, ammonium nitrate, and potassium sulfate While stirring, keep the reaction temperature at 70°C and the reaction time for 40 minutes to form a viscous fluid;

[0083

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap