Violet-LED excited blue fluorescent powder and preparation method thereof

A technology of blue phosphor and purple light, which is applied in the field of blue phosphor, can solve the problems of unresolved excitation and emission intensity, low luminous intensity, and low purity of phosphor powder, and achieve high commercial application value, high luminous intensity, and raw materials Easy to get effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] According to another aspect of the present invention, the present invention provides a preparation method of the blue phosphor excited by the above-mentioned purple light LED, the method comprising the following steps:

[0023] Step 1: According to the chemical structural formula M of the blue phosphor 1-x MgSi 5 Al 10 o 27 :xEu 2+ For the stoichiometric numbers shown, the raw material MCO was weighed separately 3 , MgCO 3 , SiO 2 、Al 2 o 3 and Eu 2 o 3 , mix these raw materials evenly with flux, and put them into a mortar and grind them thoroughly;

[0024] Step 2: calcining the above-mentioned ground materials in a reducing atmosphere at a temperature of 1100-1300° C. for 5-10 hours, cooling and pulverizing after calcining to obtain the blue fluorescent powder of the present invention.

[0025] In the first step, the flux is selected from AlF 3 , NH 4 F. Li 2 CO 3 、H 3 BO 3 , NaCO 3 One or more of them, and preferably AlF 3 ; The amount of flux is 0.1w

Embodiment 1

[0030] Weigh 0.99mol CaCO according to the chemical structural formula of the blue phosphor 3 , 1.0mol MgCO 3 , 5.0mol SiO 2 , 5.0mol Al 2 o 3 , 0.005mol Eu 2 o 3 As a raw material, the flux AlF of 0.4wt% of the total mass of the raw material was weighed 3 To mix with the raw material, put the weighed raw material and flux into the mortar and grind, grind for 10min, and sieve the ground material through a 300-mesh sieve to obtain the sieved material;

[0031] Place the above-mentioned sieved material in a crucible, weigh 10wt% activated carbon powder of the total mass of the above-mentioned raw material, place it around the crucible where the raw material is located, and calcinate under the reducing atmosphere created by these activated carbon powders. The calcining temperature is 1100°C. Time 10h; after calcination, the calcined product is taken out, cooled and pulverized to obtain the required Ca 0.99 MgSi 5 Al 10 o 27 :0.01Eu 2+ Phosphor.

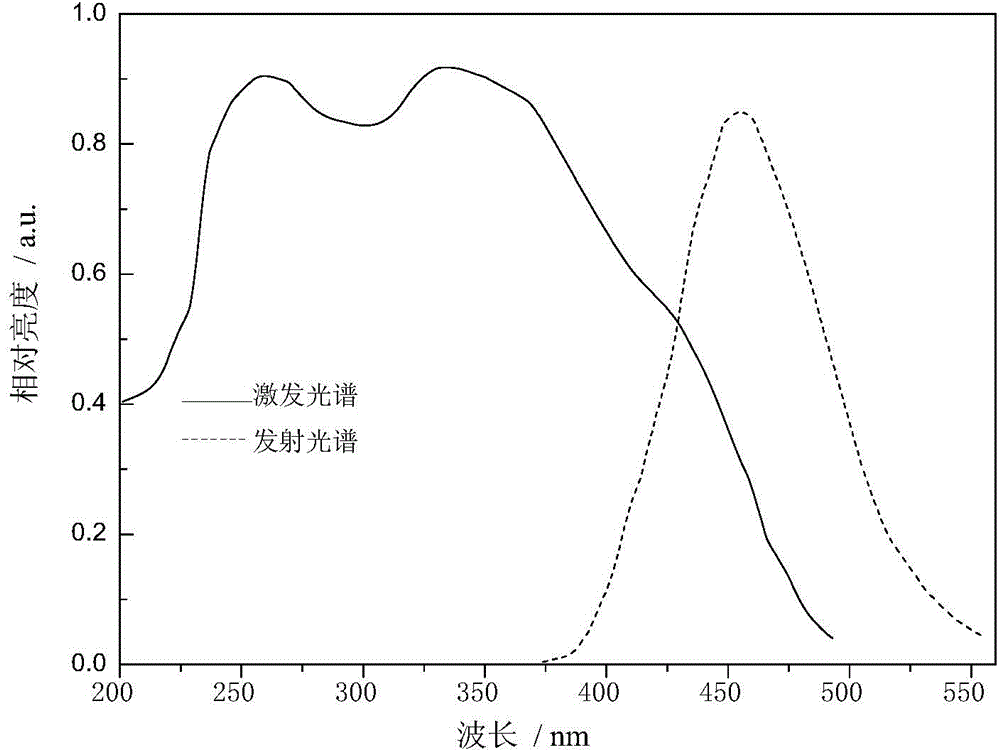

[0032] figure 1 shows t

Embodiment 2

[0034] Weigh 0.97mol SrCO according to the chemical structural formula of the blue phosphor 3 , 1.0mol MgCO 3 , 5.0mol SiO2 , 5.0mol Al 2 o 3 , 0.015mol Eu 2 o 3 As a raw material, weigh 0.5wt% flux H of the total mass of the raw material 3 BO 3 To mix with the raw material, put the weighed raw material and flux into the mortar and grind, grind for 10min, and sieve the ground material through a 300-mesh sieve to obtain the sieved material;

[0035] Place the above-mentioned sieved material in a crucible, weigh 12wt% activated carbon powder of the total mass of the above-mentioned raw material, place it around the crucible where the raw material is located, and calcinate under the reducing atmosphere created by these activated carbon powders. The calcining temperature is 1150°C. Time 9h; after calcination, the calcined product is taken out, cooled and pulverized to obtain the required Sr 0.97 MgSi 5 Al 10 o 27 :0.03Eu 2+ Phosphor.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ll | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap