Automatic firework and firecracker powder preparing and mixing system

A mixing system and automatic preparation technology, applied in explosives, explosives processing equipment, offensive equipment and other directions, can solve the problems of increasing the danger of drug mixing process, increasing the risk, occupational health hazards of workers, etc., to prevent personal injury and safety. Improve the support ability and realize the effect of man-machine separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

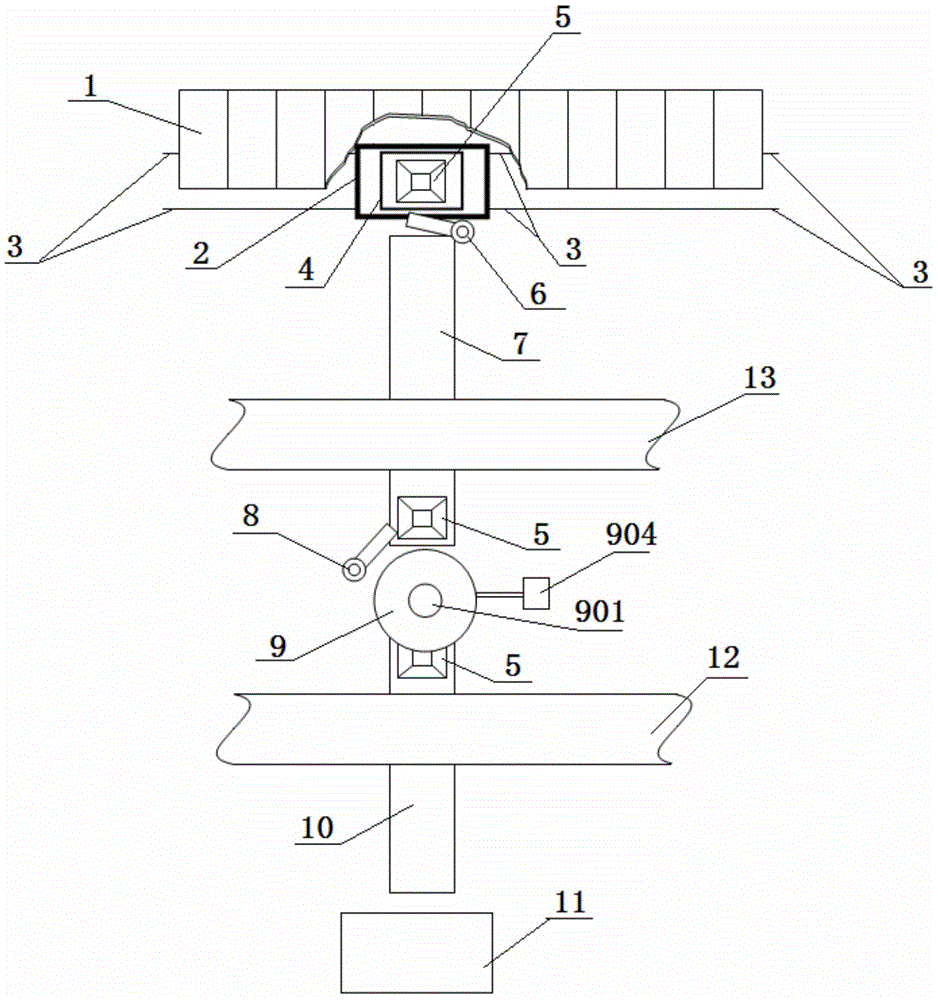

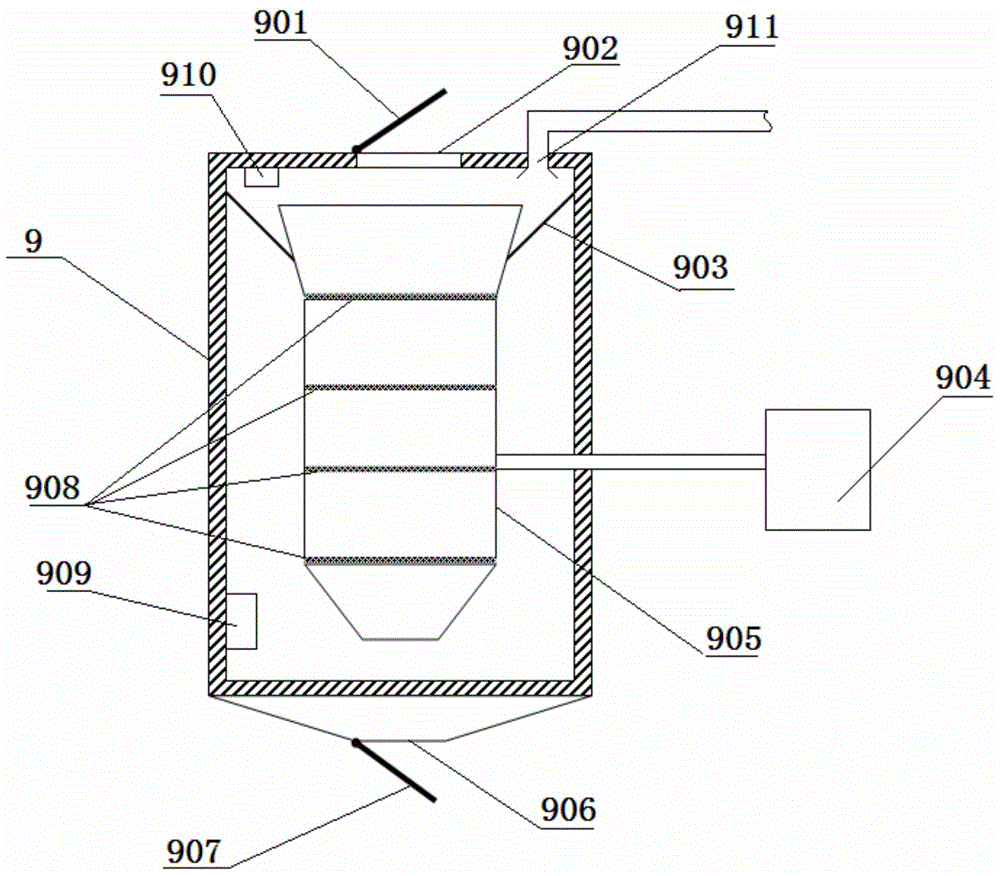

[0026] Referring to the accompanying drawings, which reflect a specific structure of the present invention, the automatic preparation and mixing system of fireworks and firecrackers includes a material preparation mechanism, a metering and preparation mechanism, a first delivery mechanism, a mixing mechanism, and a second delivery mechanism; it also includes an automatic control mechanism. The control mechanism communicates with each working mechanism, and controls each working mechanism to automatically coordinate and operate according to the set procedure:

[0027] Material preparation mechanism: various single materials are crushed and sieved and stored in twelve special containers 1 for standby. The bottom of the special container 1 is equipped with a discharge port with an automatic valve (not shown in the figure). The special container 1 has an identification code , the automatic valve communicates with the automatic control mechanism;

[0028] Measuring and preparing mecha

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap