Horizontal casting machine

A casting machine, horizontal technology, applied in casting equipment, equipment for feeding molten metal into molds, metal processing equipment, etc., can solve problems such as damage, laborious formwork, affecting product quality, etc., so that it is not easy to tilt and deviate, and is applicable Wide range and good equipment stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

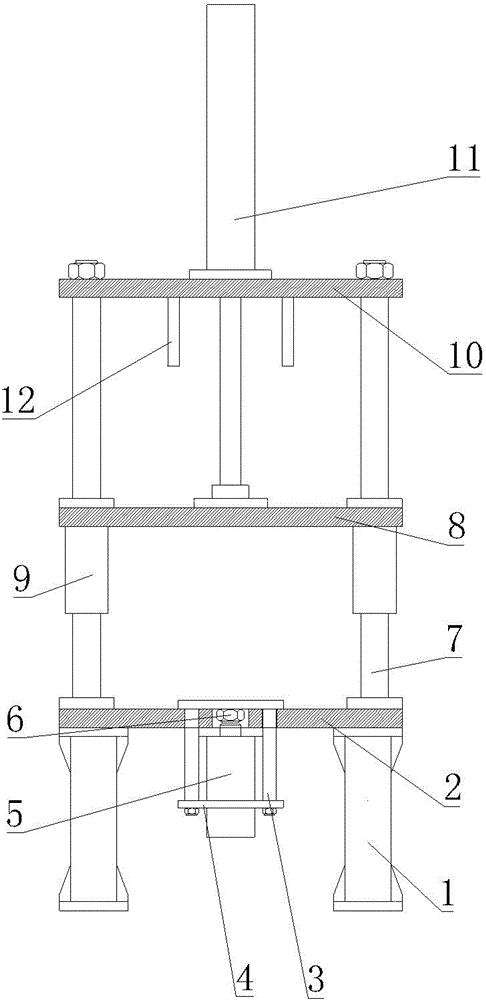

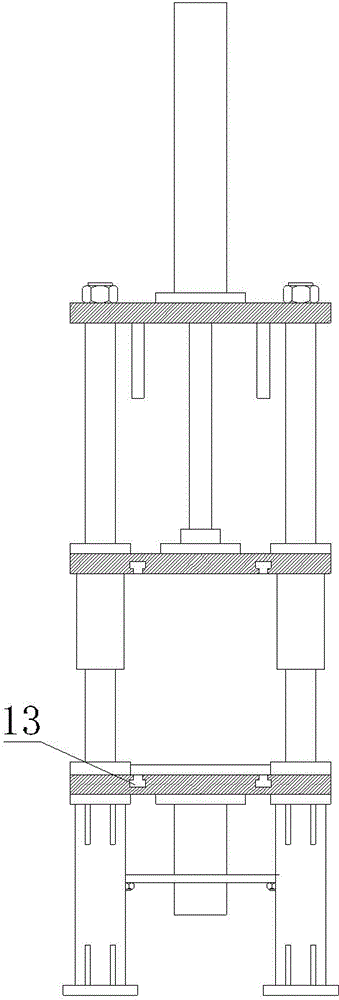

[0013] See figure 1 , figure 2 , the present invention includes a lower fixed formwork 2 installed on a foot 1, the lower end of the lower fixed formwork 2 is connected with a mounting plate 4 through a screw 3, a core-pulling oil cylinder 5 is fixed on the mounting plate 4, and the piston rod of the core-pulling oil cylinder 5 extends upwards The top block 6 is installed on the top of the piston rod, the four corners of the lower fixed template 2 are respectively provided with guide pillars 7, the four corners of the movable template 8 are respectively provided with guide sleeves 9, and the movable template 8 passes through the guide pillars 7 and the guide sleeves. 9 is mounted on the guide post 7 with sliding fit, the top of the guide post 7 is fixedly connected with the upper fixed formwork 10, and the upper fixed formwork 10 is fixed with a lifting

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap