High-efficiency high-reliability low-cost sealing apparatus for gas tightness detection of motorcycle fuel tank

A technology of air tightness detection and sealing device, which is applied in the direction of using liquid/vacuum degree for liquid tightness measurement, etc. It can solve the problems of low work efficiency, easy wear of cam, deformation of fuel tank port, etc., and achieve labor-saving operation and reliable sealing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

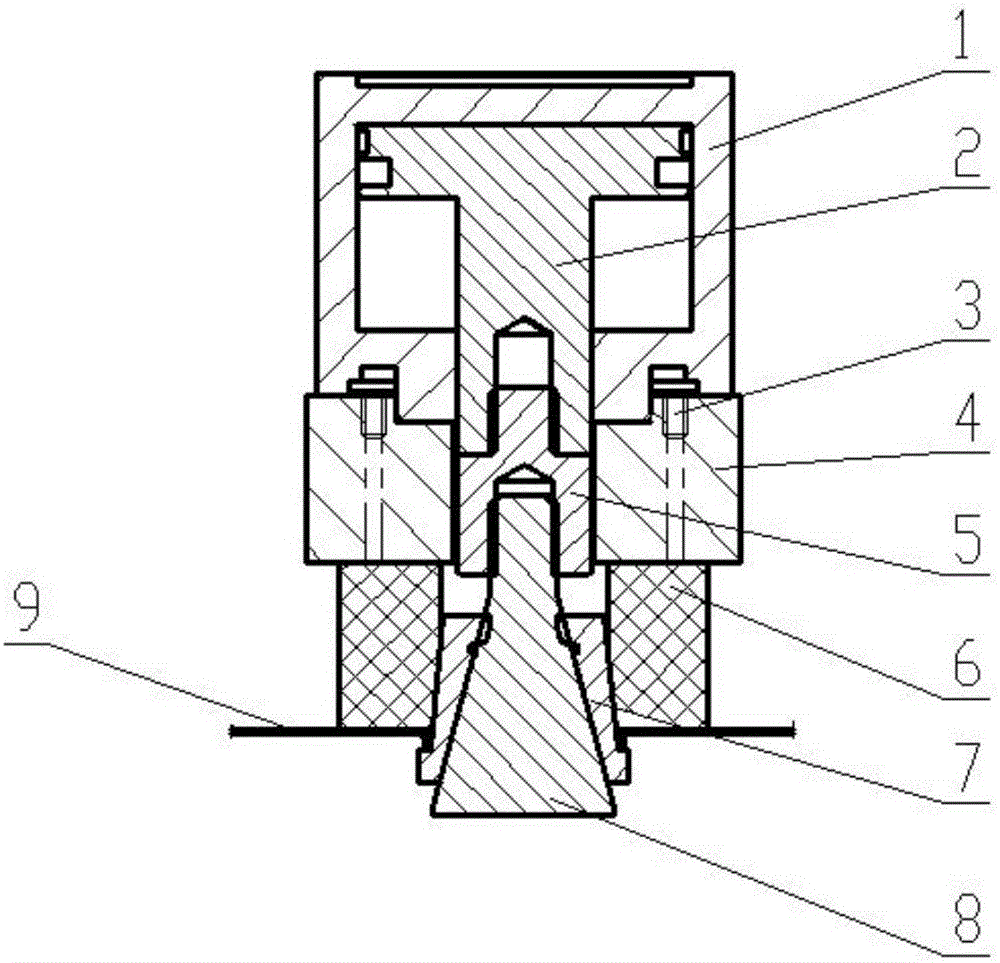

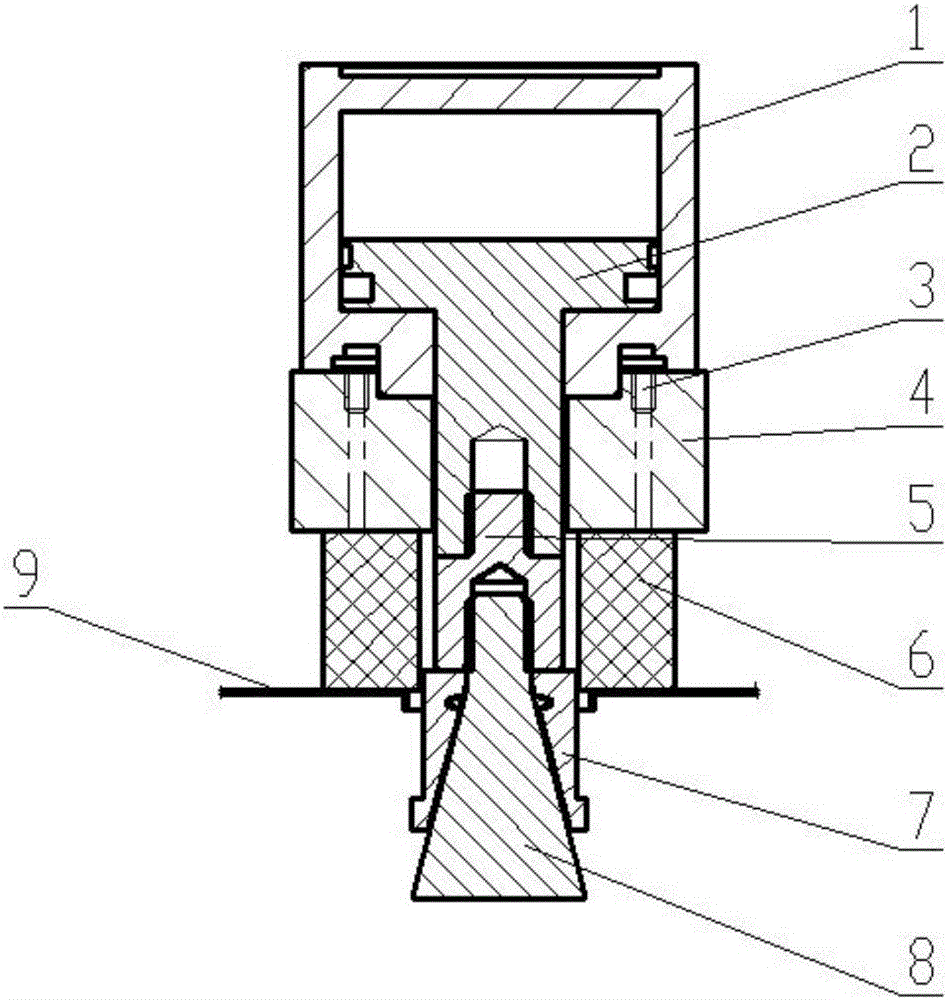

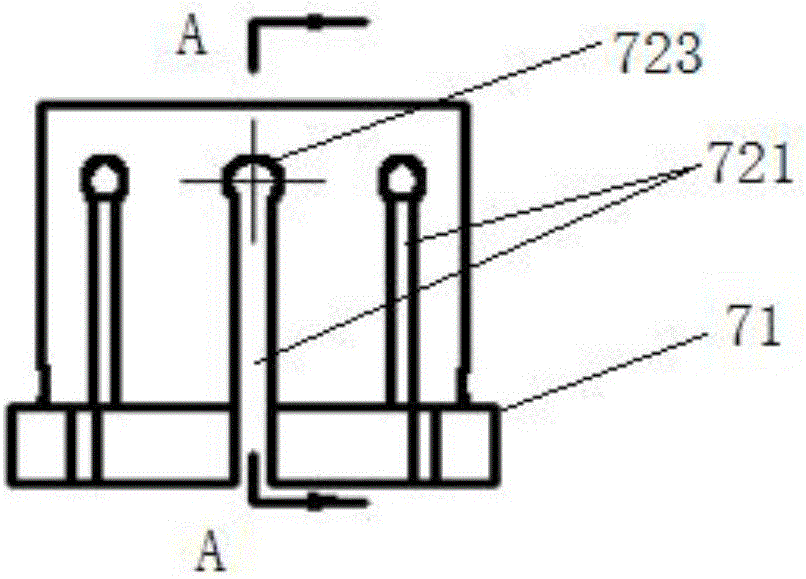

[0024] see Figure 1-Figure 6 , a kind of embodiment of the sealing device used for motorcycle fuel tank air tightness detection, comprises support plate 4, and the lower end surface of support plate 4 is provided with hollow rubber pad 6, and the rubber pad 6 is slidingly fitted with hollow elastic expansion bladder 7 There is a pull rod 8 slidingly fitted in the elastic expander 7, and the pull rod 8 is in the shape of a small upper portion and a larger lower portion. The bending part 71, the upper end of the pull rod 8 protrudes from the elastic expansion tube 7 and is dynamically connected with a tension device. When the pull rod 8 moves upward, the bending part 71 of the elastic expansion tube 7 is driven to contact the fuel tank port 9 to form a limit, and the elastic expansion tube 7 radially expands and compresses the rubber pad 6 to f...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap