Mechanism with double degrees of freedom

A degree of freedom, linear motor technology, applied in the direction of electromechanical devices, control mechanical energy, electrical components, etc., can solve the problems of maximum speed limit, difficult to achieve high-speed and high-precision positioning, and achieve high accuracy and acceleration, and compact structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the accompanying drawings.

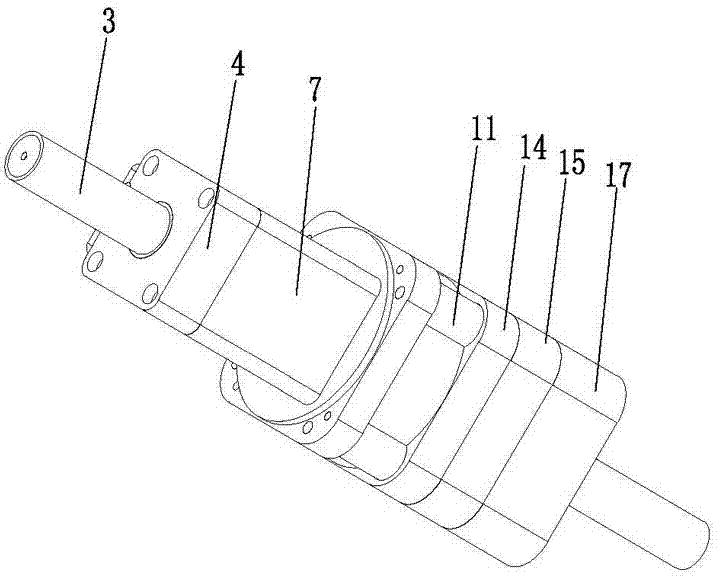

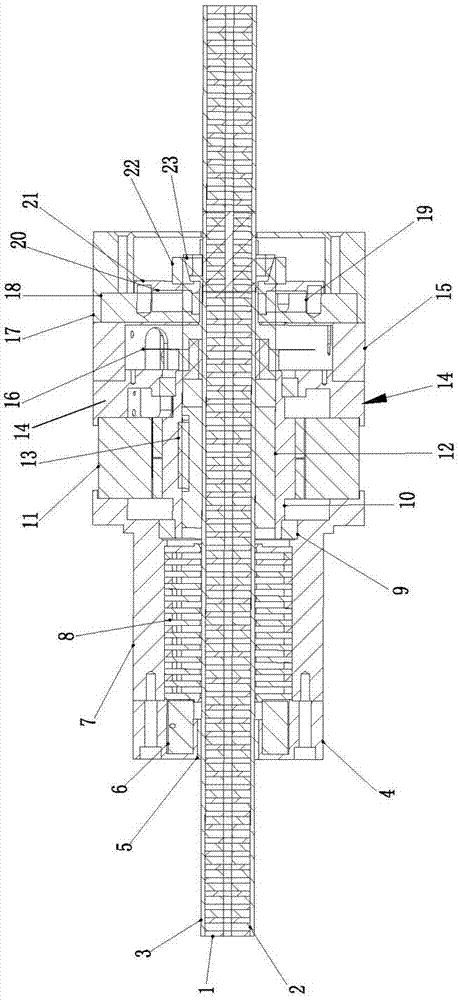

[0025] as attached figure 1 with 2 As shown, the present invention discloses a two-degree-of-freedom mechanism, including a housing 7, which is provided with a linear motor and a direct drive rotary motor, and the linear motor includes a linear motor stator 8 housed in the housing 7 , the linear motor mover 3 and the self-lubricating bearing 5, the linear motor mover 1 passes through the self-lubricating bearing 5 and the linear motor stator 8 and cooperates with the linear motor stator 8 in clearance; the direct drive rotary motor includes a rotary motor stator 11 and The rotor 10 of the rotating electrical machine, the stator 11 of the rotating electrical machine is installed on the casing 7, the rotor 10 of the rotating electrical machine is clamped on the casing 7 and is located between the casing

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap