Auxiliary agent component-containing boehmite and/or pseudo boehmite, and applications thereof

A boehmite, additive-containing technology, applied in alumina/aluminum hydroxide, catalyst carrier, other chemical processes, etc., can solve the problem of alumina specific surface area, pore volume reduction, pseudo-boehmite or thin water The problems such as the increase of bauxite grains can achieve the effect of realizing grain growth, improving relative crystallinity and inhibiting the growth of grains.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] Alumina hydrate containing auxiliary agent provided by the invention and preparation thereof:

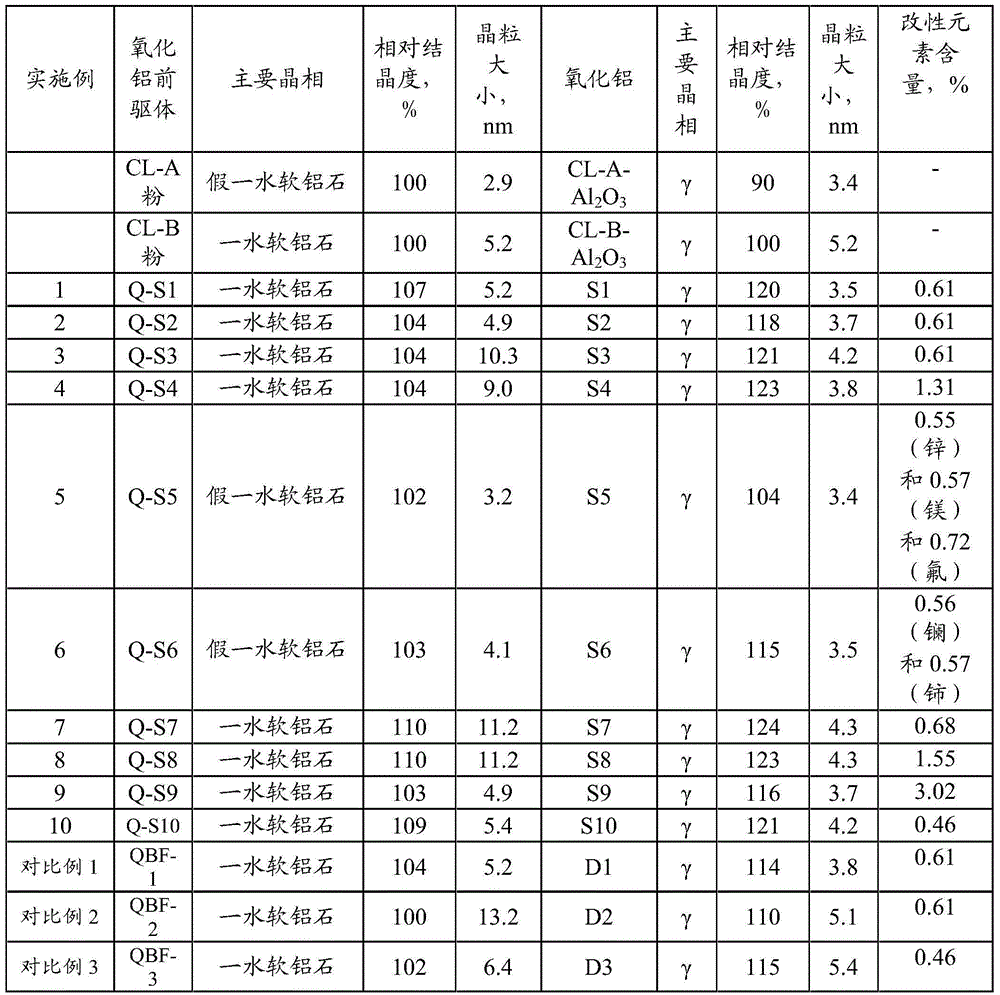

[0069] Weigh 364 grams of CL-A powder and 110 grams of CL-A-600 powder on a dry basis (the mass ratio of CL-A-600 powder to CL-A powder on a dry basis is 0.30), and combine them with Mix 3600 grams of deionized water, add 10.78 grams of ammonium dihydrogen phosphate, and stir to form a slurry; transfer the slurry to a stainless steel autoclave with a stirring volume of 5 liters and a Teflon liner, and heat it to 160 ℃ for 4 hours; after cooling down to room temperature and filtering, the filter cake was dried at 120 ℃ for 8 hours to obtain hydrated alumina Q-S1 containing additives. The crystal phase, crystallinity and grain size were characterized by X-ray diffraction method, and the results are listed in Table 1.

[0070] Formed alumina provided by the invention and its preparation:

[0071] Q-S1 was extruded into a clover-shaped strip with a circumscribed circle diameter of

Embodiment 2

[0073] Alumina hydrate containing auxiliary agent provided by the invention and preparation thereof:

[0074]Weigh 235 grams of CL-A powder and 296 grams of CL-A-600 powder on a dry basis (the mass ratio of CL-A-600 powder to CL-A powder on a dry basis is 1.26), and weigh them Mix with 3600 grams of deionized water, and add 12.08 grams of ammonium dihydrogen phosphate, and stir to form a slurry; transfer the slurry to a stainless steel autoclave with a stirring volume of 5 liters and a Teflon liner, and heat it to Constant temperature at 160°C for 4 hours; after cooling down to room temperature and filtering, the filter cake was dried at 120°C for 8 hours to obtain hydrated alumina Q-S2 containing additives. The crystal phase, crystallinity and grain size were characterized by X-ray diffraction method, and the results are listed in Table 1.

[0075] Formed alumina provided by the invention and its preparation:

[0076] Q-S2 is extruded into a clover-shaped strip with a circumsc

Embodiment 3

[0078] Alumina hydrate containing auxiliary agent provided by the invention and preparation thereof:

[0079] Weigh 126 grams of CL-A powder and 453 grams of CL-A-600 powder on a dry basis (the mass ratio of CL-A-600 powder to CL-A powder on a dry basis is 3.60), and add 13.21 grams of ammonium dihydrogen phosphate, mix them with 3600 grams of deionized water and stir to form a slurry; transfer the slurry to a stainless steel autoclave with a stirring volume of 5 liters and a Teflon liner, heat it to 160 ℃ for 4 hours; after cooling down to room temperature and filtering, the filter cake was dried at 120 ℃ for 8 hours to obtain hydrated alumina Q-S3 containing additives. The crystal phase, crystallinity and grain size were characterized by X-ray diffraction method, and the results are listed in Table 1.

[0080] Formed alumina provided by the invention and its preparation:

[0081] Q-S3 is extruded into a clover-shaped strip with a circumscribed circle diameter of 1.6 millimete

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap