Swinging inhibition device of C-shaped LNG liquid tank

A liquid tank and intermediate position technology, applied in the direction of bulk cargo, etc., can solve the problems of complex structure, limited sway control effect, limited sway control effect, etc., and achieve the effect of obvious sway control effect and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The structure of the present invention will be further described below with reference to the accompanying drawings.

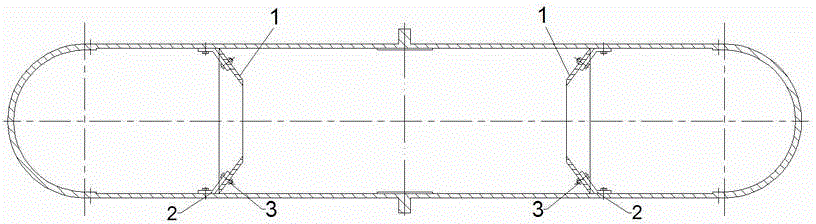

[0012] figure 1 A structural diagram of a C-type LNG liquid tank sloshing device is shown. In the figure, the sloshing device of the C-type LNG tank includes the C-type LNG tank and two swaying rings 1, and the two swaying rings 1 are respectively arranged symmetrically with the middle position of the C-type LNG tank through the connecting gasket 2 And fixed on the inner wall of the C-type LNG liquid tank, the oscillating ring 1 adopts a conical ring structure, the diameter of the cone bottom of the conical ring structure is consistent with the inner diameter of the C-type LNG liquid tank, and the cone top of the conical ring structure The hole faces the middle of the Type C LNG tank. The connecting gasket 2 adopts a square steel plate with a folded corner. There are two round holes on the connecting gasket 2. One round hole is fixedly connected with the

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap