Continuous production method for microwave fixation of organic flat tea

A technology of microwave fixing and production method, which is applied in the direction of tea treatment before extraction, etc., can solve the problems of gray color of tea leaves, affecting the quality of tea leaves, and blackening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the objects and advantages of the present invention clearer, the present invention will be specifically described below in conjunction with examples. It should be understood that the following words are only used to describe one or several specific implementation modes of the present invention, and do not strictly limit the protection scope of the specific claims of the present invention.

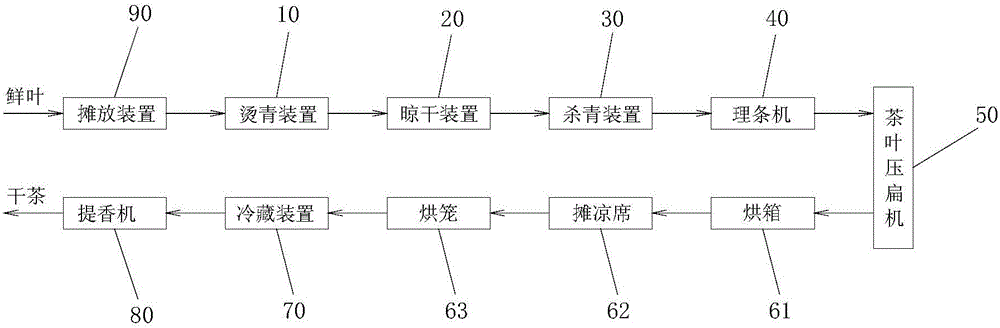

[0027] The continuous production system provided by the invention for organic flat tea microwave finishing, such as figure 1 As shown, it includes a spreading device 90 for spreading the tea leaves which are connected in sequence, a scalding device 10 for scalding the tea leaves, a drying device 20 for drying the tea leaves, and a drying device 20 for drying the tea leaves. A de-greening device 30 for de-greening tea leaves, a straightening machine 40 for de-greening tea leaves, a tea flattening machine 50 for flattening and shaping tea leaves, an oven 61 for performing

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap