Epicyclic gear

A kind of cruise star, conjoined technology, applied in the field of cruise star, can solve the problems of increased cost, cannot be reused, damaged, etc., to achieve the effect of improving production efficiency, better effect, and avoiding collapse points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the objects and advantages of the present invention clearer, the present invention will be further described in detail below through embodiments in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention.

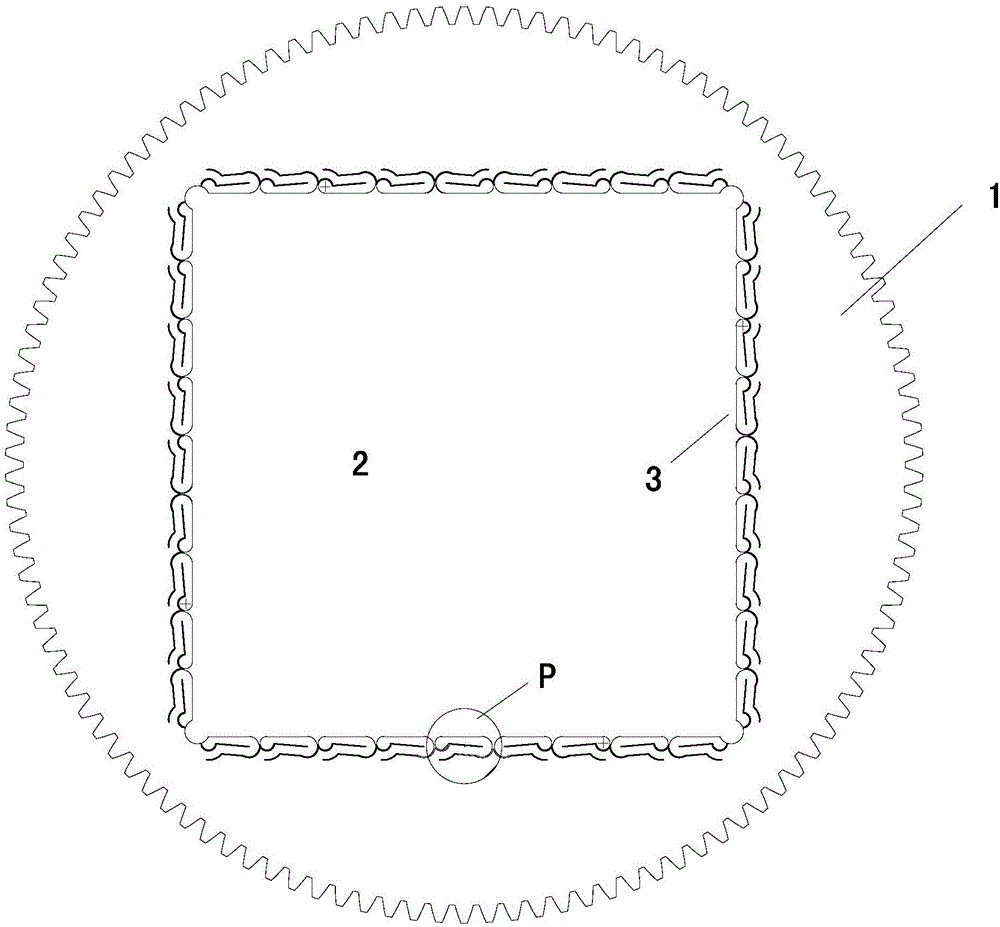

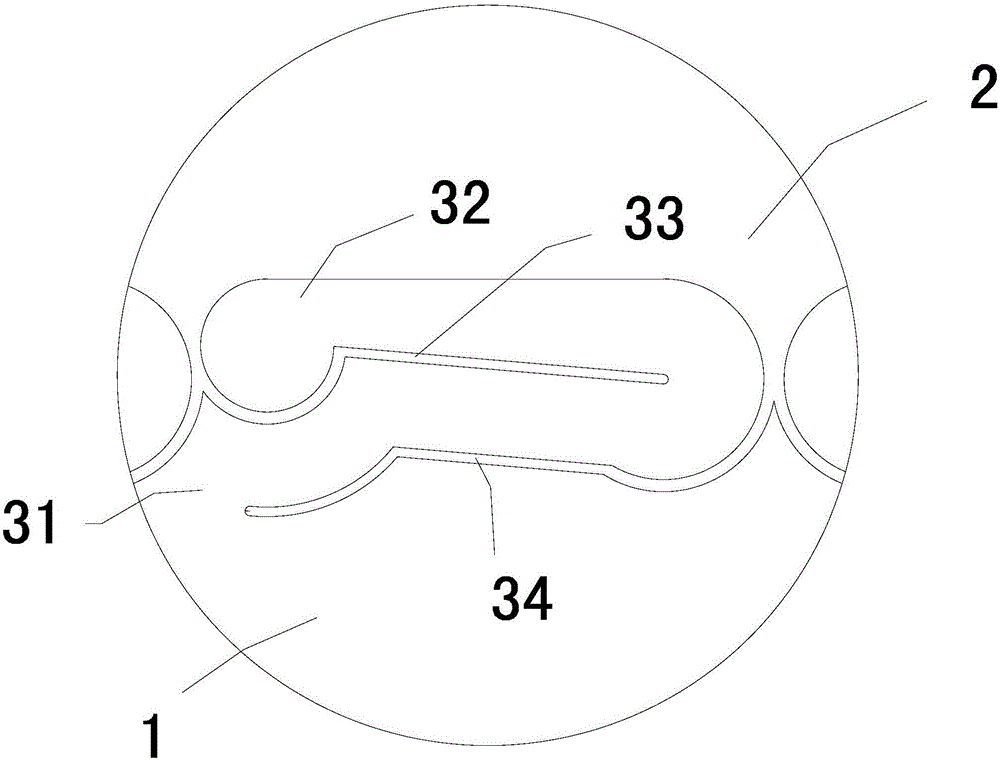

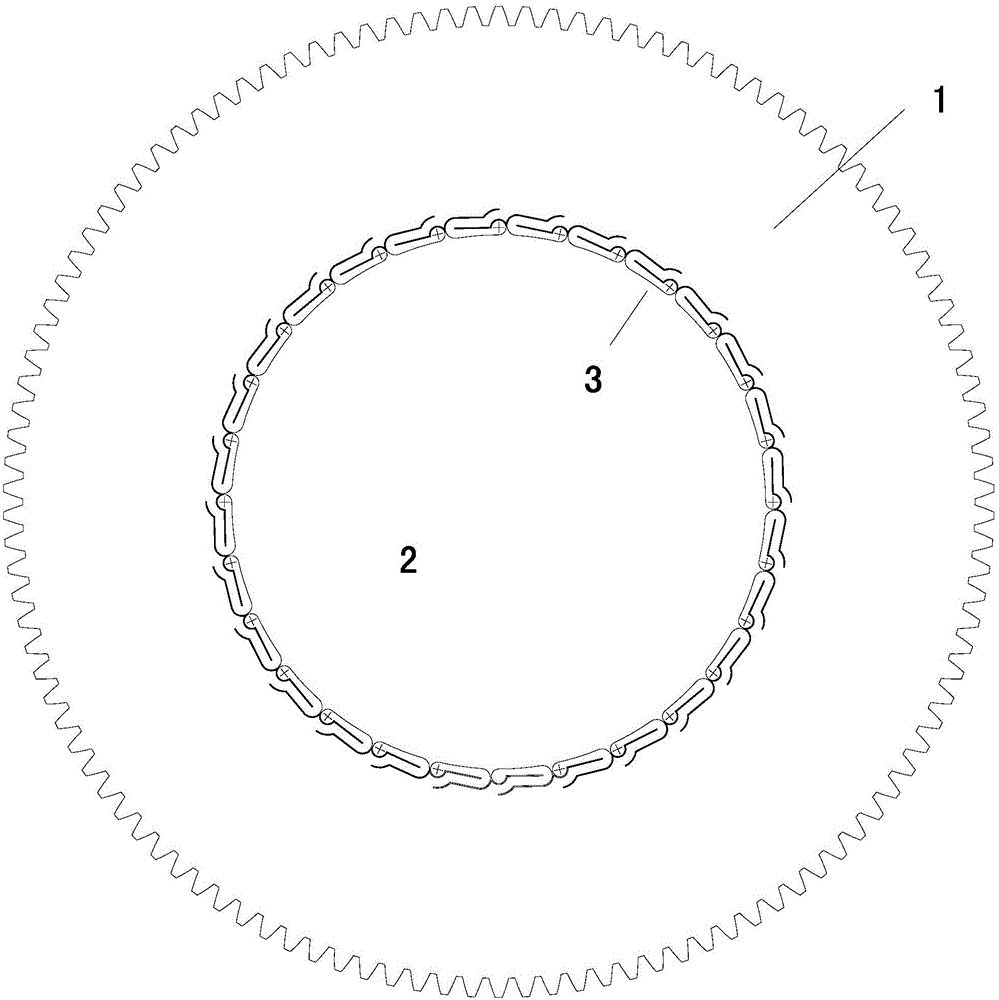

[0019] see figure 1 -3. figure 1 Only one workpiece hole is drawn, and the hole is different from image 3 The round hole in the workpiece is a square hole, which can be said to be a special-shaped hole, and the grinding and polishing of mobile phone touch screens is usually such a hole. How many workpiece holes are set in the middle part of each star wheel body 1 depends on the size of the star wheel and the size of the workpiece.

[0020] Using laser or wire electric discharge cutting method, the planetary wheel is made of blue steel sheet to form elastic conjoined bodies 3 extending from the main body 1 an

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap